The Versatility and Applications of Pierced Sheet Metal

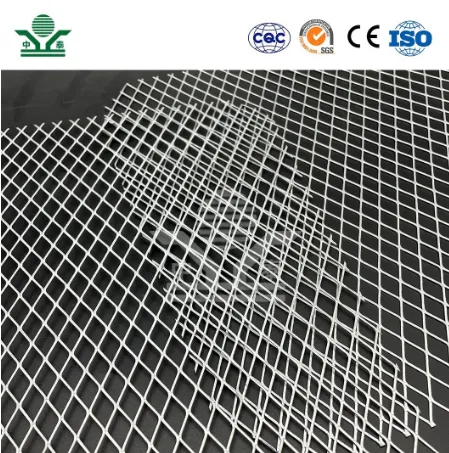

Pierced sheet metal is a fascinating material that has found its way into numerous applications across various industries. This specialized form of metalworking involves creating holes or patterns in sheet metal, which can significantly enhance its functional and aesthetic qualities. The process of piercing not only contributes to the metal's weight reduction but also provides benefits like improved airflow, increased surface area for painting or coating, and enhanced flexibility in design.

Understanding Pierced Sheet Metal

Pierced sheet metal is typically made from materials such as steel, aluminum, and copper. The perforation can come in numerous shapes and sizes, depending on the intended application. The methods used to pierce the metal can vary, with common techniques including laser cutting, punching, and stamping. Each method has its advantages, with laser cutting offering precise cuts, while punching can be more economical for mass production.

One of the key benefits of pierced sheet metal is its ability to reduce weight without sacrificing strength. By removing strategic sections of the metal, manufacturers can create lightweight structures that are both durable and functional. This attribute is particularly valuable in industries such as automotive and aerospace, where the challenge of weight reduction is constant.

Applications of Pierced Sheet Metal

The applications of pierced sheet metal are widespread and diverse. In the architectural world, it is often used in building facades, sunshades, and decorative screens. The patterns created through the piercing process not only serve aesthetic purposes but also contribute to energy efficiency by allowing natural light to filter through while reducing direct sunlight exposure.

In the HVAC industry, pierced sheet metal is commonly used for ductwork

. The perforations improve airflow, making heating and cooling systems more efficient. Furthermore, in the field of electronics, perforated metal is used in enclosures and casings to provide ventilation for cooling mechanisms.pierced sheet metal

Another notable application is in the manufacturing of industrial equipment. Components such as filters are often made from perforated sheet metal, taking advantage of the material's ability to allow fluids or gases to pass through while filtering out impurities. This characteristic is crucial in industries like food processing, pharmaceuticals, and environmental management.

Advantages of Pierce Sheet Metal

The benefits of using pierced sheet metal extend beyond functionality. The aesthetic versatility provided by various hole patterns allows designers to create unique products that stand out in the marketplace. Decorative elements made from perforated metal can be seen in furniture design, art installations, and even in consumer products.

Moreover, pierced sheet metal can also lead to cost savings in production. The ability to manufacture lighter parts reduces shipping costs and makes assembly easier. Additionally, the innate properties of metals allow for high levels of recycling, making pierced sheet metal an environmentally friendly choice in a time when sustainability is a crucial concern for many companies.

Conclusion

In conclusion, pierced sheet metal is a prime example of how innovation and traditional techniques can converge to create materials that are both practical and visually appealing. Its applications across various industries showcase its versatility and importance. As technology advances and the demand for sustainable materials grows, the significance of pierced sheet metal is only expected to increase.

Whether it's enhancing architectural designs, optimizing systems for air flow, or contributing to the efficiency of industrial processes, pierced sheet metal has solidified its place as an essential element in modern manufacturing and design. The future is bright for this unique material, and its continued development will undoubtedly lead to exciting new applications.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.