Feb . 07, 2025 00:49

Back to list

perforated tin sheets

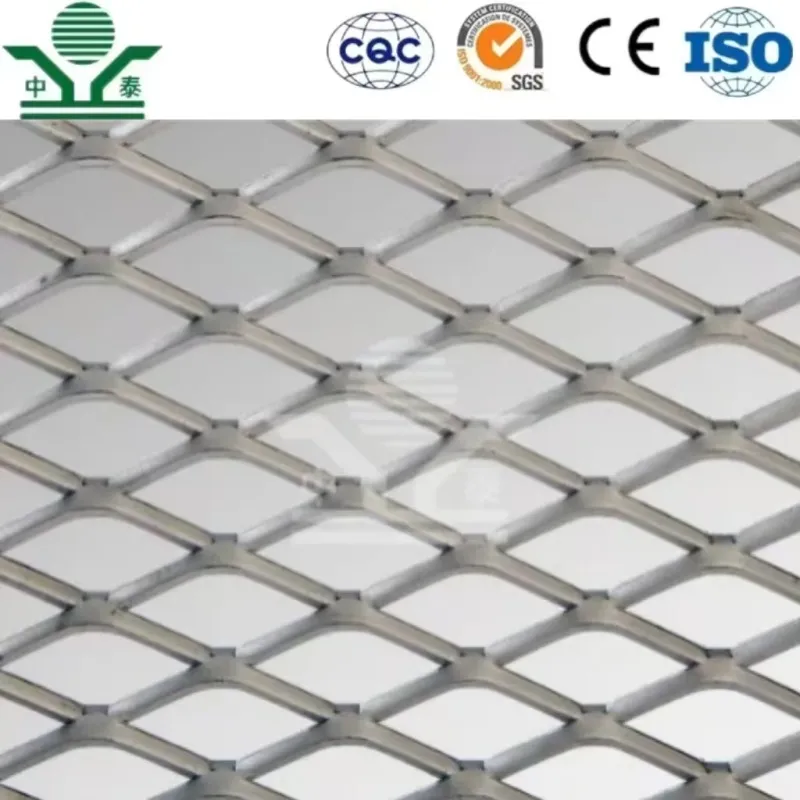

Perforated tin sheets have steadily gained recognition in various industries due to their versatility, durability, and cost-effectiveness. These sheets, crafted from tin, feature an array of small holes, meticulously punched for functional and aesthetic purposes. Their unique characteristics make them ideal for numerous applications across different sectors.

The environmental benefits of using perforated tin sheets cannot be overlooked. Tin is a recyclable material, aligning with sustainable development and manufacturing practices. The lifecycle of tin products contributes to reduced environmental impact, as they can be reprocessed and reused, promoting a circular economy. Industries focusing on sustainability often opt for perforated tin sheets as a green alternative to other materials, solidifying its reputation as an eco-friendly option. Explore the benefits of perforated tin sheets in creative projects such as interior design or art installations. Their aesthetic appeal is unparalleled, offering endless possibilities for creativity. When used in interior spaces, these sheets can be backlit to create stunning visual effects or serve as a unique room divider, allowing designers to craft distinctive environments. In terms of regulatory compliance, perforated tin sheets meet various industry standards, ensuring they adhere to safety and quality criteria. This compliance is a testament to their credibility as a reliable material across different sectors. Whether used in construction, manufacturing, or design, they provide peace of mind with their proven performance and adherence to stringent quality standards. Despite their many benefits, potential users might face challenges selecting the appropriate specifications for their intended application. Consultation with experts during the selection process is crucial to maximize their functional and aesthetic advantages. By doing so, businesses and individuals can ensure they harness the full potential of perforated tin sheets in their projects. In summary, perforated tin sheets are celebrated for their versatility, durability, and sustainability. From enhancing architectural designs to improving industrial efficiencies, their applications are as varied as they are effective. The combination of technical expertise, environmental benefits, and compliance with industry standards positions perforated tin sheets as a trusted and authoritative choice across multiple domains.

The environmental benefits of using perforated tin sheets cannot be overlooked. Tin is a recyclable material, aligning with sustainable development and manufacturing practices. The lifecycle of tin products contributes to reduced environmental impact, as they can be reprocessed and reused, promoting a circular economy. Industries focusing on sustainability often opt for perforated tin sheets as a green alternative to other materials, solidifying its reputation as an eco-friendly option. Explore the benefits of perforated tin sheets in creative projects such as interior design or art installations. Their aesthetic appeal is unparalleled, offering endless possibilities for creativity. When used in interior spaces, these sheets can be backlit to create stunning visual effects or serve as a unique room divider, allowing designers to craft distinctive environments. In terms of regulatory compliance, perforated tin sheets meet various industry standards, ensuring they adhere to safety and quality criteria. This compliance is a testament to their credibility as a reliable material across different sectors. Whether used in construction, manufacturing, or design, they provide peace of mind with their proven performance and adherence to stringent quality standards. Despite their many benefits, potential users might face challenges selecting the appropriate specifications for their intended application. Consultation with experts during the selection process is crucial to maximize their functional and aesthetic advantages. By doing so, businesses and individuals can ensure they harness the full potential of perforated tin sheets in their projects. In summary, perforated tin sheets are celebrated for their versatility, durability, and sustainability. From enhancing architectural designs to improving industrial efficiencies, their applications are as varied as they are effective. The combination of technical expertise, environmental benefits, and compliance with industry standards positions perforated tin sheets as a trusted and authoritative choice across multiple domains.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP