Understanding Perforated Steel Sheet Sizes A Comprehensive Guide

Perforated steel sheets have gained significant popularity across various industries due to their versatile functionality and aesthetic appeal. These sheets, characterized by their unique patterns of holes punched into them, offer not only structural support but also an element of design. One of the most critical factors to consider when working with perforated steel sheets is their size, as it can greatly influence their application and effectiveness.

What Are Perforated Steel Sheets?

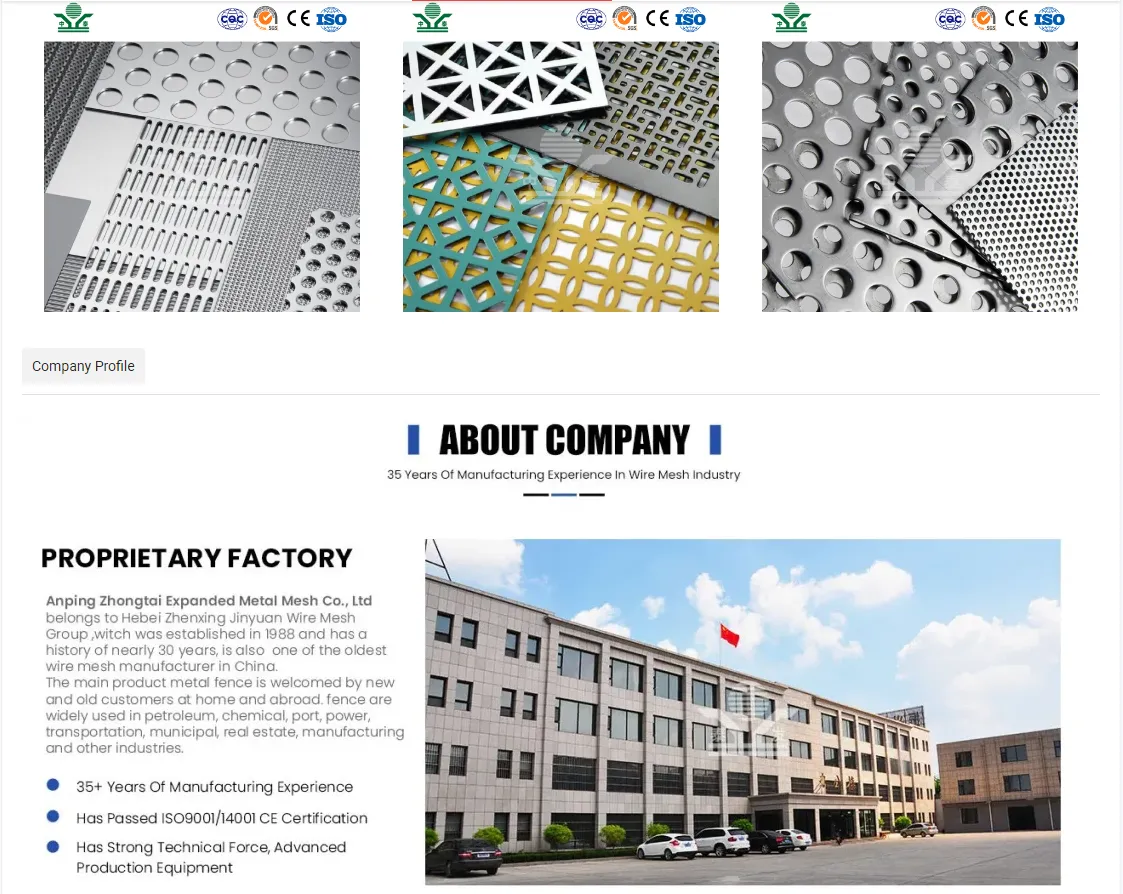

Perforated steel sheets are metal sheets that have been mechanically punched to create a pattern of holes. These holes can vary in size, shape, and spacing, allowing for customization based on specific needs. The primary materials used in the manufacturing of perforated sheets include mild steel, stainless steel, and aluminum, which can be selected based on factors such as corrosion resistance, strength, and weight.

Importance of Sizes

When it comes to perforated steel sheets, the sizes available on the market can be extensive. These sheets are often produced in standard sizes, but custom dimensions can also be manufactured to meet particular project requirements. The size of a perforated sheet affects its application in numerous ways. Here are some core considerations

1. Application Specificity Different applications may require different sheet sizes. For instance, architectural applications, such as facades or decorative elements, might demand larger sheets with intricate patterns, while industrial uses may necessitate smaller sheets that can fit specific machinery or structures.

2. Load-Bearing Considerations The size of a sheet also impacts its load-bearing capabilities. Larger sheets might distribute weight differently than smaller sheets, influencing their performance in construction and engineering applications. Understanding the weight and loading conditions is key in selecting the proper size for your project.

perforated steel sheet sizes

3. Installation and Handling Larger perforated sheets can be cumbersome to handle and install, especially in tight spaces or complex structures. Conversely, smaller sheets may be easier to manage but could require more joints and fasteners, complicating the installation process.

4. Cost Implications Size plays a significant role in cost. Larger sheets might come at a higher price point due to material and shipping costs. However, they can also provide savings by minimizing the need for additional pieces, reducing waste, and lowering labor costs associated with handling multiple smaller sheets.

Common Sizes and Customization

Perforated steel sheets commonly come in various sizes, including but not limited to 4x8 feet, 3x6 feet, and 2x4 feet. The thickness of these sheets generally ranges from 16 gauge to 1/4 inch, allowing for flexibility in strength and weight. However, businesses are increasingly opting for customized sizes to meet specific requirements. This flexibility in dimensions ensures that perforated sheets can seamlessly integrate into projects of all scales.

When considering customization, it’s essential to collaborate with manufacturers who can offer advice on hole sizes, patterns, and spacing that will work best for the intended application. Common hole patterns include round, square, and slots, and each pattern can influence airflow, light transmission, and aesthetic appeal.

Conclusion

Choosing the right size for perforated steel sheets is vital for ensuring their effectiveness in your project. Whether you require large sheets for a significant construction endeavor or smaller sheets for specific industrial use, understanding your options will help you make informed decisions. The versatility and customizability of perforated steel sheets enable creative possibilities, transforming standard materials into innovative design elements while providing functional benefits.

By taking the time to evaluate the application, load requirements, handling considerations, and cost implications, you can select the ideal perforated steel sheet size that meets your project's unique needs. As industries continue to embrace these materials for their diverse applications, the importance of informed size selection becomes increasingly paramount, ensuring successful project outcomes and maximized efficiencies.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.