The Versatility and Applications of Perforated Steel Sheet Metal

Perforated steel sheet metal is a remarkable material that has gained increasing popularity in various industries due to its unique properties and versatility. Made by punching holes into a sheet of steel, this product allows for a multitude of applications ranging from architectural use to industrial processes. The creation of these sheets not only enhances their aesthetic appeal but also their functionality, offering a blend of strength, durability, and designer-friendly features.

One of the primary advantages of perforated steel sheet metal is its ability to provide structural integrity while allowing for lightweight construction. The holes punched into the material reduce weight without sacrificing strength. This makes it an optimal choice for various structural applications where reducing overall weight is desirable, such as in roofing, walls, and other building materials. Additionally, the perforations can help in controlling airflow and light, making it an ideal element in both industrial and commercial design.

In architectural applications, perforated steel is celebrated for its aesthetic potential. Designers and architects utilize these sheets to create intricate patterns and facades that not only enhance the visual appeal of a building but also serve functional purposes such as natural ventilation and light filtering. Perforated panels can significantly enhance energy efficiency by allowing natural light to permeate indoor spaces while reducing the need for artificial lighting. The customization options available for hole sizes, shapes, and spacing further empower architects to meet specific design intents without compromising on functionality.

perforated steel sheet metal

Moreover, perforated steel sheet metal is extensively used in various industries, from manufacturing to food processing. In industrial settings, they are often employed as filters, grates, and trays in processes that require the separation of materials or the support of heavy items. The holes in the sheets allow for easy drainage and airflow, which is particularly beneficial in processes involving liquids or gases. For instance, in the food industry, perforated sheets are used for baking trays and fry baskets, ensuring that heat is evenly distributed while allowing grease to drain away efficiently.

Sustainability is another key benefit of using perforated steel sheet metal. Steel is recyclable, and using perforated designs can minimize waste during manufacturing processes. As industries increasingly shift towards more sustainable practices, materials like perforated steel are becoming essential components of environmentally-conscious design.

The versatility of perforated steel sheet metal extends to various sectors, including interior design, automotive, and HVAC systems. With its myriad applications, it has cemented its position as a go-to material for those seeking a balance of form and function.

In conclusion, perforated steel sheet metal is not just a functional material but also an innovative solution in modern design and industrial applications. Its ability to blend strength, aesthetic appeal, and versatility makes it an essential choice for architects, designers, and engineers alike. Whether in constructing buildings or creating innovative products, perforated steel is sure to be at the forefront of contemporary material use.

-

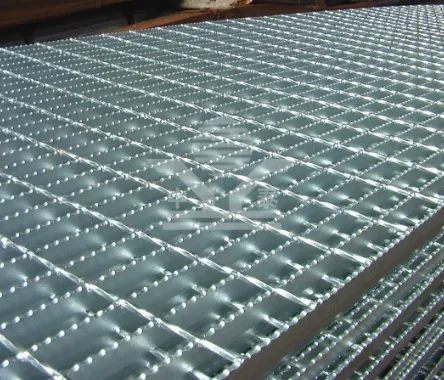

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.