The Benefits and Applications of Perforated Steel Screens

Perforated steel screens have emerged as versatile and essential components in various industries. Characterized by their unique patterns of holes, these screens offer a combination of strength, lightweight design, and excellent functionality. They are utilized for filtration, ventilation, and aesthetic purposes across numerous applications, showcasing both practicality and style.

One of the primary advantages of perforated steel screens is their ability to facilitate effective airflow and fluid movement. In industrial sectors, these screens are crucial for separation processes—be it in mining, food processing, or chemical manufacturing. By allowing certain particles or liquids to pass through while restricting others, perforated screens enhance efficiency and productivity. This filtering capability is also vital in environmental applications, such as water treatment, where they help remove debris and contaminants, ensuring cleaner, safer water supplies.

In construction and architecture, perforated steel screens serve both functional and aesthetic roles. Architects often incorporate these screens into building designs, using them as facades or sunshades. The patterns created by perforations can reduce heat gain and glare, improving energy efficiency while adding a modern, artistic element to structures. Moreover, these screens can provide privacy without sacrificing natural light, making them ideal for residential and commercial spaces alike.

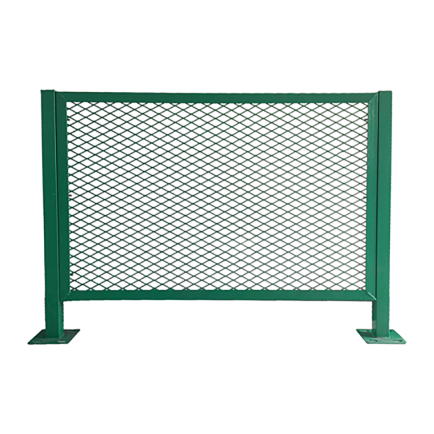

perforated steel screen

The manufacturing process of perforated steel screens has evolved significantly over the years. Modern technology enables precision engineering, allowing for custom hole sizes, shapes, and patterns tailored to specific needs. This adaptability ensures that perforated steel screens can meet the demands of various applications, from HVAC systems to decorative wall panels. Their durability, coupled with corrosion resistance properties, makes them a long-lasting choice for both indoor and outdoor environments.

In terms of maintenance, perforated steel screens are relatively easy to clean and maintain. Their robust construction means they can withstand harsh conditions, minimizing the need for frequent replacements. Regular cleaning helps maintain their functionality and aesthetic appeal, ensuring they continue to perform well over time.

Another significant aspect of perforated steel screens is their contribution to sustainability. By optimizing processes such as air and water filtration, they help reduce waste and energy consumption. Furthermore, many manufacturers are moving towards eco-friendly practices, using recycled materials in the production of perforated screens, thereby minimizing their environmental impact.

In conclusion, perforated steel screens offer a myriad of benefits and applications across various industries. Their ability to facilitate airflow, enhance architectural design, and contribute to sustainable practices makes them an indispensable component in modern applications. As technology advances and design trends evolve, the use of perforated steel screens is likely to expand further, solidifying their place in both functional and aesthetic domains.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.