The Versatility of Perforated Stainless Steel Strips

Perforated stainless steel strips have emerged as a prominent material across various industries, thanks to their unique combination of durability, aesthetics, and functionality. This article explores the various applications, advantages, and characteristics of perforated stainless steel strips, emphasizing why they have become a choice material for designers, engineers, and manufacturers.

At its core, perforated stainless steel refers to sheets or strips of stainless steel that have been drilled or punched with a series of holes. These perforations can vary in size, shape, and pattern, allowing for a high degree of customization. The inherent properties of stainless steel, such as resistance to corrosion, high strength-to-weight ratio, and ease of maintenance, further enhance the appeal of perforated strips.

One of the key applications of perforated stainless steel strips is in the architectural sector. Designers and architects often utilize these strips in facades, railings, and screens to not only provide functional benefits but also to add a modern touch to structures. The perforations allow for the passage of light and air, creating an interplay of shadows and textures that can greatly enhance the aesthetic appeal of a building. Additionally, these strips can serve as effective noise barriers, especially in urban environments where sound pollution is a concern.

perforated stainless steel strip

In the manufacturing and industrial sectors, perforated stainless steel strips are invaluable. They are frequently used in the production of filters, sieves, and grilles. Their strength and durability ensure that they can withstand rigorous conditions, while their perforated design allows for efficient flow of materials, air, or liquids. For instance, in the food processing industry, perforated strips can facilitate the draining of liquids without compromising structural integrity.

Moreover, the lightweight nature of perforated stainless steel strips makes them ideal for use in transportation. In the automotive and aerospace industries, these materials contribute to weight reduction while maintaining safety and performance standards. The ability to customize the strip's perforation pattern allows engineers to optimize performance based on specific aerodynamic requirements.

Another significant benefit of perforated stainless steel strips is their contribution to sustainability. Stainless steel is 100% recyclable, which means that materials used in applications can be reprocessed and repurposed, promoting an eco-friendly approach. The durability of stainless steel ensures that products will have a long lifespan, reducing the need for frequent replacements and contributing to resource conservation.

In conclusion, perforated stainless steel strips offer an array of advantages across many applications. Their versatility, strength, aesthetic value, and sustainability make them an essential material in modern design and engineering. As industries continue to innovate, the demand for such materials will undoubtedly grow, positioning perforated stainless steel strips as a cornerstone of contemporary manufacturing and architecture.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

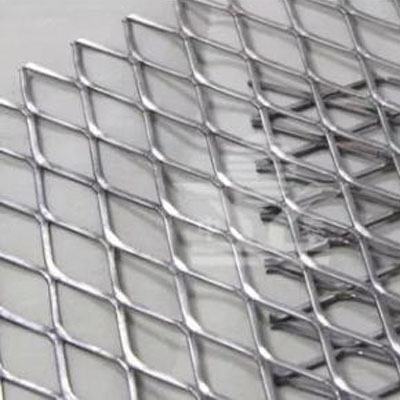

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.