The Versatility of Perforated Stainless Steel Mesh

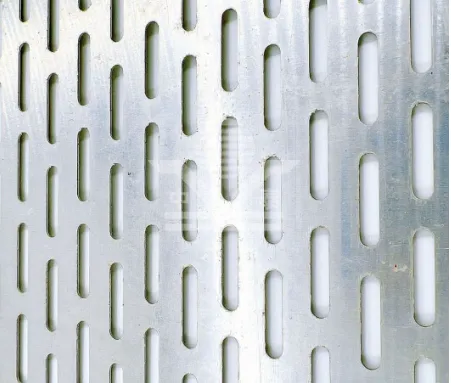

Perforated stainless steel mesh is a remarkable material that finds application in various industries due to its unique combination of strength, durability, and aesthetic appeal. This engineered product consists of stainless steel sheets that have been punched with a series of holes, creating a mesh-like structure. The result is a lightweight yet strong material that offers a plethora of functionalities.

One of the primary advantages of perforated stainless steel mesh is its corrosion resistance. Stainless steel, by its nature, contains chromium, which forms a protective layer on the surface of the metal. This layer prevents rust and corrosion, making perforated stainless steel particularly suitable for environments exposed to moisture, chemicals, or extreme temperatures. As a result, it is commonly used in outdoor applications, including architectural features, facades, and fencing.

The aesthetic versatility of perforated stainless steel mesh also contributes to its widespread use in modern architecture and design. Architects and designers appreciate the ability to create visually striking and functional structures. The mesh can be customized in terms of hole size, arrangement, and sheet thickness, allowing for creative architectural designs that provide both light and ventilation. This adaptability makes it a popular choice for building facades, sunshades, and decorative screens.

perforated stainless steel mesh

In addition to its architectural applications, perforated stainless steel mesh is extensively used in industrial settings. It serves as a filtration medium in processing plants, where it can separate solids from liquids and gases. Its strength and durability make it ideal for use in high-stress environments, such as manufacturing and mining. Furthermore, the perforations in the mesh allow for easy flow of air, liquids, and sound, making it an excellent choice for noise reduction applications in industrial equipment.

The food and beverage industry also benefits significantly from perforated stainless steel mesh. Due to its non-reactive nature and ease of cleaning, this material is often used in food processing equipment, such as screens, strainers, and conveyor baskets. It ensures that products remain uncontaminated while allowing thorough washing and drainage, which is crucial for maintaining hygiene and safety standards.

Moreover, the energy efficiency of perforated stainless steel mesh cannot be overlooked. In HVAC systems, for instance, the mesh can be used in air filters, promoting better airflow while minimizing energy consumption. This property aligns with the growing trend of sustainable and energy-efficient building practices.

In conclusion, perforated stainless steel mesh stands out as a multifaceted material with a diverse range of applications across numerous industries. From architecture to filtration and beyond, its unique combination of strength, corrosion resistance, aesthetic appeal, and functionality has made it an essential component in modern manufacturing and design. As industries continue to evolve and seek innovative solutions, the popularity and utility of perforated stainless steel mesh are sure to endure, marking its significance in contemporary applications.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.