The Versatility of Perforated Slotted Metal Sheets

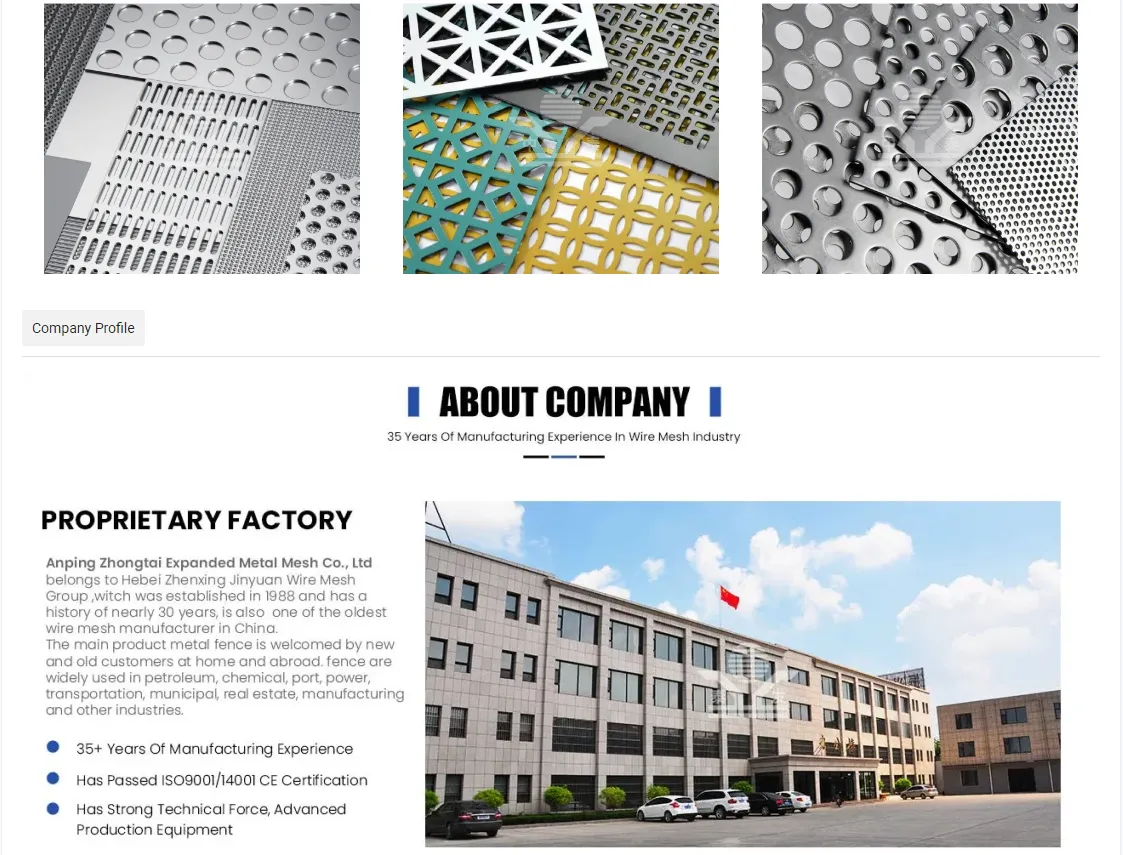

Perforated slotted metal sheets are increasingly gaining popularity across various industries due to their unique combination of strength, functionality, and aesthetic appeal. A perforated slotted metal sheet is crafted by punching holes and slots into a sheet of metal, resulting in a material that is both lightweight and structurally sound. This article explores the multifaceted applications, advantages, and manufacturing processes of perforated slotted metal sheets, highlighting their role in modern engineering and architecture.

Diverse Applications

One of the most significant advantages of perforated slotted metal sheets is their versatility. They are commonly used in the construction industry for architectural facades, railings, and canopies. The perforations can be designed in various patterns, providing not only functional utility but also aesthetic enhancements. For example, a perforated screen can shroud a building to create a dynamic interplay of light and shadow, enhancing the visual appeal while also providing ventilation and reducing solar heat gain.

In industrial applications, these metal sheets serve as filters, sound barriers, and mechanical covers. They are frequently used in the design of HVAC systems for airflow management, ensuring efficient ventilation and reducing noise levels. Additionally, they are employed in the manufacturing of machinery and equipment, serving as protective covers that allow for necessary airflow while keeping out debris.

Perforated slotted metal sheets are also prevalent in the automotive sector, where they are utilized for grilles, panels, and diffusers

. Their lightweight nature helps improve fuel efficiency while maintaining the structural integrity required for safety.Advantages

The use of perforated slotted metal sheets comes with a range of notable advantages. First and foremost is their strength-to-weight ratio. Despite being perforated, these sheets retain impressive load-bearing capabilities, making them ideal for a wide array of applications without adding excessive weight.

perforated slotted metal sheet

Moreover, the customizability of perforated patterns allows for a tailored solution to specific needs. Manufacturers can create sheets with different hole sizes, shapes, and distributions to suit unique project requirements. This adaptability ensures that engineers and designers can achieve both functionality and aesthetic beauty.

Another major advantage is the ability of perforated sheets to enhance acoustic performance. The holes in the metal allow sound waves to penetrate and dissipate, making these sheets ideal for environments where noise reduction is crucial, such as concert halls and theaters.

Manufacturing Processes

The production of perforated slotted metal sheets involves several key steps. Initially, a metal sheet, typically made of materials like stainless steel, aluminum, or mild steel, is selected based on the intended application. The sheet is then subjected to a perforation process where holes and slots are punched through the material using hydraulic or mechanical presses. This process can be highly automated, allowing for mass production of sheets with consistent quality.

Post-perforation, the sheets may undergo additional treatments such as cleaning, finishing, or coating to enhance their durability and appearance. Treatments like powder coating or galvanization can protect against corrosion, extending the life of the product in harsh environments.

Conclusion

In conclusion, perforated slotted metal sheets are an essential component in numerous industries, ranging from construction and manufacturing to automotive and acoustics. Their blend of strength, versatility, and aesthetic appeal makes them a preferred choice for many applications. As technology continues to evolve, the manufacturing processes and design possibilities for these sheets are likely to expand, further establishing them as a vital resource in modern engineering and design. Whether utilized for practical or decorative purposes, perforated slotted metal sheets are sure to remain influential in shaping the future of various industries.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.