Understanding Perforated Sheet Sizes A Comprehensive Guide

Perforated sheets are versatile materials widely used in various industries, offering a balance between aesthetics and functionality. These sheets, characterized by a series of holes punched through them, provide unique benefits that cater to different applications, from architectural designs to industrial processing. A key factor in utilizing perforated sheets effectively is understanding the various sizes and configurations available. This article will delve into the significance of perforated sheet sizes, their applications, and considerations to keep in mind when selecting the right size for your project.

What Are Perforated Sheets?

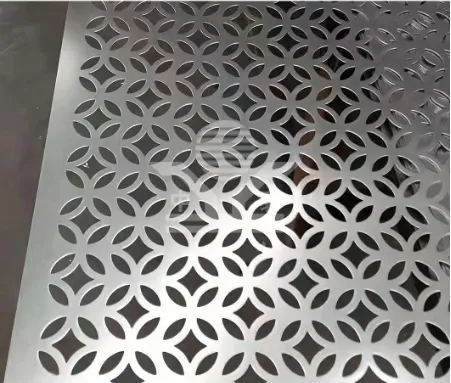

Perforated sheets are made from materials like metal, plastic, or composite materials that have been drilled or punched with a pattern of holes. The holes can vary in size, shape, and spacing, creating different effects and functionalities. The perforation allows for ventilation, filtration, and aesthetic appeal, making them a popular choice in modern design.

Common Sizes and Patterns

Perforated sheets can be custom made to specific sizes, but there are standard dimensions available for convenience. Common sheet sizes typically include

- 4x8 feet - 4x10 feet - 5x10 feet

These standard sizes can often be cut down to the required dimensions depending on the project’s needs. Hole sizes may range from tiny (1/8 inch) to large (1 inch or more), depending on the intended use. Additionally, the pattern may either be round, square, or decorative shapes, which adds to its aesthetic flexibility.

Applications of Perforated Sheets

1. Architecture and Design In building and interior design, perforated sheets are utilized in facades, partitions, and ceilings. The holes allow for light and air to pass through while maintaining privacy. Decorative patterns can enhance visual appeal, contributing to the overall design theme.

2. Industrial Uses In manufacturing, perforated sheets play a vital role in filtration applications, allowing liquids or gases to pass while retaining larger particles. They are also used in screen applications, enabling the separation of materials in a process.

perforated sheet sizes

3. Acoustic Solutions Perforated sheets are employed in sound absorption and control solutions. The holes can help reduce noise levels in various environments, making them essential in both commercial and residential settings.

4. Automotive Industry In the automotive sector, perforated sheets are often used in parts such as grilles, speaker covers, and air conditioning vents, allowing for the necessary airflow while offering a degree of protection.

Choosing the Right Size

When selecting perforated sheets, it's crucial to consider both the size of the sheet and the hole configuration. Here are some factors to consider

- Purpose of Use Define the primary function of the perforated sheet. Will it be used for aesthetic purposes, filtration, or sound absorption? Each application may require different hole sizes and patterns.

- Material Type The choice of material affects the thickness and strength of the perforated sheet. For outdoor applications, galvanized steel or aluminum may offer better corrosion resistance.

- Installation Space Measure the area where the perforated sheet will be installed. Ensure the dimensions align with your design and functional requirements, keeping in mind that custom sizes may incur additional costs.

- Regulations and Standards In some applications, particularly in construction and manufacturing, local regulations may dictate specific requirements for sizes and materials. Always check to ensure compliance.

Conclusion

Perforated sheets are a valuable component across many sectors, providing practical benefits while enhancing aesthetic appeal. Understanding the various sizes and configurations available is essential for selecting the appropriate sheet for your specific needs. By considering factors such as application, material, and size requirements, you can ensure optimal performance and satisfaction with your final choice. Whether you're working on an architectural project or an industrial application, the right perforated sheet can make all the difference.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.