Understanding the Price of Perforated Sheets per Square Foot

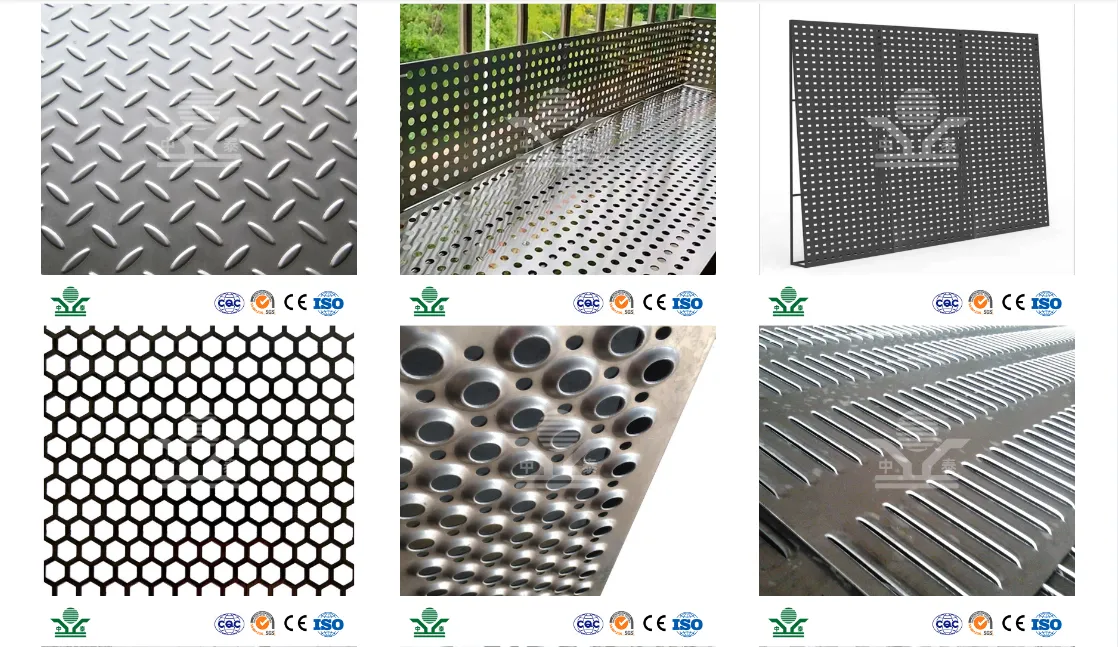

Perforated sheets are versatile materials used in a wide range of applications, including architecture, construction, industrial processes, and interior design. These sheets are characterized by holes that are punched through their surface, creating a pattern that not only enhances aesthetic appeal but also serves functional purposes such as ventilation, noise reduction, and filtering. One of the critical considerations for anyone looking to purchase perforated sheets is the price per square foot, which can vary significantly based on several factors.

Factors Influencing Perforated Sheet Prices

1. Material Type The material from which the perforated sheet is made plays a significant role in its price. Common materials include stainless steel, aluminum, brass, and plastic. Stainless steel sheets are typically more expensive due to their durability and corrosion resistance, while aluminum sheets can be more affordable yet still provide good strength and lightweight options.

2. Sheet Thickness The thickness of the perforated sheet also impacts cost. Thicker sheets tend to be more expensive due to the additional material and the manufacturing processes involved. Depending on the application, choosing the right thickness is essential, as it affects both strength and flexibility.

3. Hole Size and Pattern The size and arrangement of holes can influence prices as well. Custom patterns or larger holes may require more complex manufacturing processes, thereby increasing the cost. Conversely, standard patterns with uniform hole sizes might be less expensive, as they may be produced in higher quantities.

4. Quantity Ordered Bulk purchases typically result in lower prices per square foot. Manufacturers often offer discounts for larger orders, which can make a significant difference for businesses needing substantial quantities for projects.

perforated sheet price per sq ft

5. Finish and Coating Some perforated sheets undergo additional treatments or coatings, such as powder coating, anodizing, or galvanizing, to enhance their resistance to corrosion, wear, and environmental factors. These finishes can add to the overall cost of the sheet.

6. Supplier and Location Prices can vary among suppliers and are often influenced by regional factors. Local suppliers may offer different pricing structures, and transport costs can also affect the overall expense, especially for heavy sheets.

Average Price Range

On average, the price of perforated sheets can range from $1.00 to $6.00 per square foot, depending on the factors mentioned above. For example, a standard aluminum perforated sheet might cost around $2.00 per square foot, while a heavy-duty stainless steel version could be priced at $4.00 or more. It is important for buyers to compare prices and specifications from various suppliers to ensure they are getting the best value for their investment.

Conclusion

When considering perforated sheets for any project, it is crucial to understand the factors that influence their pricing. By evaluating material types, thicknesses, hole designs, and finishes, as well as taking into account order quantities and supplier differences, buyers can make informed decisions that align with their budget and project requirements. Whether for architectural features, industrial applications, or decorative elements, understanding the price per square foot of perforated sheets will help ensure a successful purchase that meets both functional and aesthetic needs. As demand for these materials continues to grow in diverse sectors, staying informed about market trends and pricing strategies will be essential for both end-users and manufacturers alike.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.