Understanding the Pricing of Perforated Sheets per Kilogram

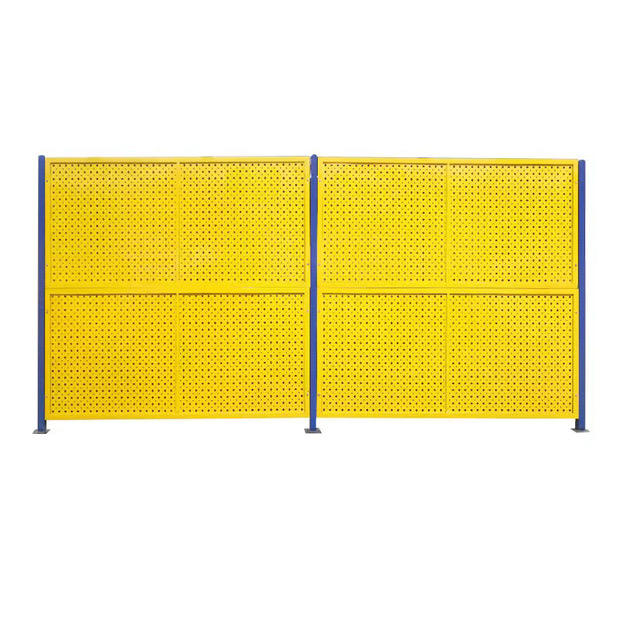

Perforated sheets have become increasingly popular in various industries due to their unique properties and versatile applications. These sheets are made from a variety of materials, including metal, plastic, and even wood, with numerous holes punched into them in specific patterns. The resulting product combines aesthetic appeal with functional benefits such as filtration, ventilation, and weight reduction. One of the crucial aspects of purchasing perforated sheets is understanding their price per kilogram, which can vary significantly based on material, thickness, size, and customization options.

Factors Influencing Price

1. Material Type The type of material used for perforated sheets is one of the primary determinants of price. Common materials include stainless steel, aluminum, mild steel, and PVC. Stainless steel, for instance, is often more expensive due to its corrosion resistance and durability, making it a preferred choice for outdoor or industrial applications. On the other hand, aluminum offers a lightweight alternative, often at a slightly lower cost.

2. Thickness and Gauge The thickness (or gauge) of the perforated sheet also plays a critical role in pricing. Thicker sheets generally cost more because they require more raw material and manufacturing effort. For example, a 2mm thick stainless steel sheet will usually be priced higher per kilogram compared to a 1mm version. When purchasing perforated sheets, it’s essential to balance the required strength and the weight needed for your application with budget constraints.

3. Hole Pattern and Size The configuration of holes, including their size, distribution, and pattern, can also impact the price. Custom designs will typically incur higher costs due to the additional manufacturing processes involved. Standard hole patterns might attract lower prices, while specialized patterns aimed at specific functions—such as sound absorption or light diffusion—may lead to increased costs.

4. Dimensions and Sheet Size The overall dimensions of the perforated sheet—length and width—will affect the price per kilogram. Larger sheets can be more cost-effective when analyzing the price per kilogram; however, they also require more material, which can skew the overall pricing.

perforated sheet price per kg

5. Volume and Bulk Orders Purchasing in bulk typically lowers the price per kilogram. Most manufacturers provide discounts based on quantity, which can significantly affect the overall costs for businesses looking to procure large amounts of perforated sheets.

Applications and Industries

The applications of perforated sheets are vast, spanning a wide range of industries including construction, aerospace, automotive, and HVAC systems. In the construction industry, they are often used for decorative facades and privacy screens. The automotive sector utilizes perforated sheets for lightweight components and noise reduction. In HVAC, these sheets serve crucial roles in air filtration and ventilation control.

Conclusion

When considering the price of perforated sheets per kilogram, it’s important to account for numerous factors, including material type, thickness, hole pattern, and order volume. By understanding these elements, buyers can make informed decisions based on their specific needs and budget. As the demand for perforated sheets continues to grow due to their versatility and functional advantages, staying informed about pricing trends can provide significant leverage for businesses ensuring they get the best value for their investment.

Ultimately, whether for architectural designs, industrial applications, or custom projects, knowing the cost implications associated with perforated sheets helps buyers navigate their options effectively, driving better project outcomes and optimizing expenses.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.