Understanding Perforated Radiator Sheets Applications and Benefits

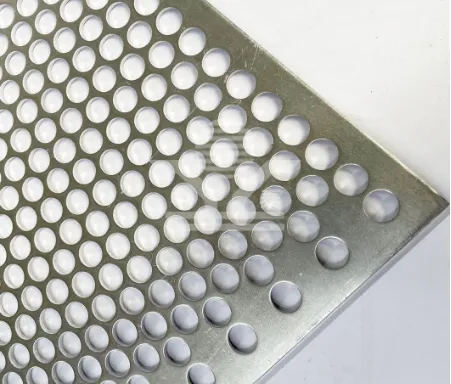

Perforated radiator sheets are specialized components used in a variety of heating and cooling applications. They are primarily made from materials like metal, which are then perforated with holes in various patterns and sizes. These sheets play a critical role in enhancing the efficiency of radiators, heat exchangers, and other thermal management systems.

The primary function of perforated radiator sheets is to facilitate the distribution of heat. When integrated into a radiator system, these sheets allow hot air or fluid to pass through, ensuring that heat is effectively transferred into the surrounding environment. The perforations increase the surface area of the sheet, which enhances heat dissipation. This increased efficiency not only maximizes the system's performance but also optimizes energy consumption, making it an eco-friendly choice for heating solutions.

One of the most significant advantages of using perforated radiator sheets is their versatility in design and application. These sheets can be customized to fit various sizes and specifications, allowing for their integration into both traditional radiators and modern heating systems. Additionally, the pattern and size of the perforations can be tailored to meet specific airflow and heat distribution needs, ensuring that each system operates at peak efficiency.

perforated radiator sheets

Moreover, perforated radiator sheets can be constructed from a variety of materials, including stainless steel, aluminum, and galvanized steel

. This allows industries to select materials that best suit their environmental conditions and aesthetic requirements. For instance, stainless steel is highly resistant to corrosion, making it an ideal choice for humid or wet environments, while aluminum is lightweight and offers excellent thermal conductivity.The manufacturing process of perforated radiator sheets usually involves laser cutting or stamping techniques, which ensure precision in the size and placement of perforations. This level of accuracy is crucial as improper perforation can lead to inefficiencies in heat transfer. High-quality perforated sheets conform to industry standards, ensuring durability and long-term performance even under extreme conditions.

Another noteworthy benefit is the aesthetic appeal of perforated radiator sheets. With increasingly modern design trends, many consumers and industries are looking for components that not only serve a functional purpose but also enhance the visual appeal of their spaces. Perforated sheets can be treated with various finishes and coatings, allowing them to blend seamlessly in both residential and commercial settings.

In conclusion, perforated radiator sheets represent a crucial innovation in heating and cooling technology. Their ability to enhance heat transfer efficiency, coupled with their versatile design and material options, makes them a practical choice for a wide array of applications. By investing in high-quality perforated sheets, industries and consumers alike can enjoy improved energy efficiency, aesthetic appeal, and overall performance of their heating systems. As technology continues to advance, we can expect further developments in this area, leading to even more efficient and eco-friendly thermal management solutions.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.