Feb . 08, 2025 06:04

Back to list

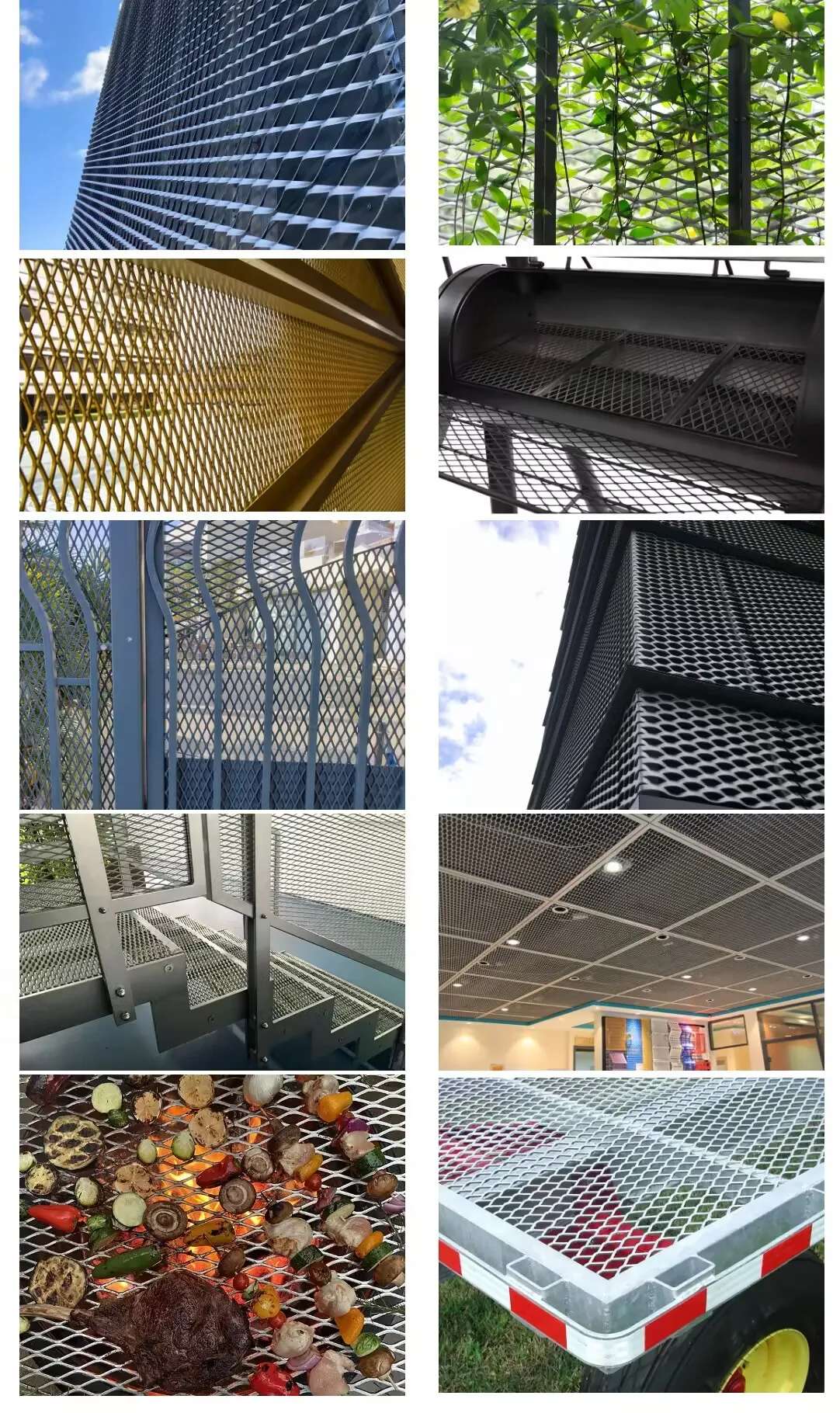

mild steel walkway mesh

Perforated mild steel sheets have carved a niche for themselves in the industrial and architectural arenas due to their versatility and resilience. They emerge as a pivotal material, adept at various applications ranging from functional to aesthetic, uniquely positioning themselves as essential components in modern design and construction.

In terms of economic benefits, cost-efficiency is a highlight of perforated mild steel sheets. Their longevity and durability reduce long-term replacement and maintenance costs. Moreover, their widespread availability and ease of manufacturing result in a lower initial investment compared to alternative materials. Companies seeking budget-friendly yet robust solutions often turn to these sheets for both major projects and everyday applications. With innovation at the forefront, incorporating digital design and laser-cutting techniques ensures that even the most complex patterns can be realized with perforated mild steel sheets. This not only maximizes functionality but also extends creativity in industrial design and architecture. Engineers and designers can push the boundaries of what is possible, crafting unique, modern structures that remain functional yet artistically expressive. Critical to their success is the trustworthiness of perforated mild steel sheets reliability proven over time. Used by seasoned professionals across various sectors, these sheets have demonstrated resilience and adaptability, affirming their role as a trusted component in both traditional and cutting-edge applications. Their ability to consistently meet rigorous standards underscores their standing in industries that demand reliability and precision. In conclusion, perforated mild steel sheets emerge as a formidable contender in both practical and creative pursuits. By merging strength with versatility, they address the nuanced requirements of modern industry and design. Their extensive application potential, coupled with environmental and economic advantages, showcases their indispensable role in advancing contemporary technological and architectural endeavors. As sectors evolve, these sheets remain at the forefront, championing both innovation and tradition while continuing to inspire confidence and reliability in their deployment.

In terms of economic benefits, cost-efficiency is a highlight of perforated mild steel sheets. Their longevity and durability reduce long-term replacement and maintenance costs. Moreover, their widespread availability and ease of manufacturing result in a lower initial investment compared to alternative materials. Companies seeking budget-friendly yet robust solutions often turn to these sheets for both major projects and everyday applications. With innovation at the forefront, incorporating digital design and laser-cutting techniques ensures that even the most complex patterns can be realized with perforated mild steel sheets. This not only maximizes functionality but also extends creativity in industrial design and architecture. Engineers and designers can push the boundaries of what is possible, crafting unique, modern structures that remain functional yet artistically expressive. Critical to their success is the trustworthiness of perforated mild steel sheets reliability proven over time. Used by seasoned professionals across various sectors, these sheets have demonstrated resilience and adaptability, affirming their role as a trusted component in both traditional and cutting-edge applications. Their ability to consistently meet rigorous standards underscores their standing in industries that demand reliability and precision. In conclusion, perforated mild steel sheets emerge as a formidable contender in both practical and creative pursuits. By merging strength with versatility, they address the nuanced requirements of modern industry and design. Their extensive application potential, coupled with environmental and economic advantages, showcases their indispensable role in advancing contemporary technological and architectural endeavors. As sectors evolve, these sheets remain at the forefront, championing both innovation and tradition while continuing to inspire confidence and reliability in their deployment.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP