Understanding Perforated Mild Steel Applications and Benefits

Perforated mild steel has gained prominence across various industries due to its unique properties and versatility. It comprises sheets of mild steel that have been subjected to a process where numerous holes are punched or drilled into the material. This article delves into the characteristics, applications, and benefits of perforated mild steel, emphasizing its significance in today's industrial landscape.

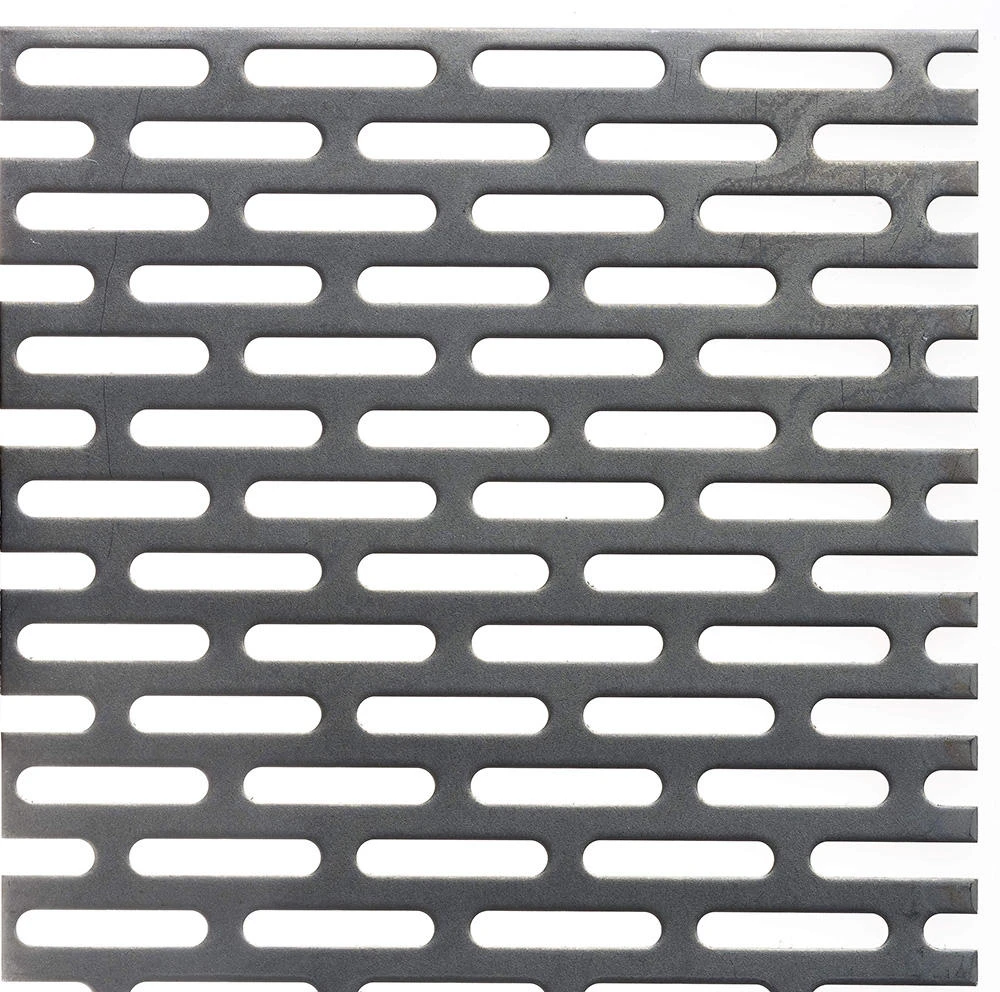

Characteristics of Perforated Mild Steel

Mild steel, known for its ductility and strength, forms the base of perforated materials. The perforation process enhances its mechanical properties, creating a material that is not only lightweight but also strong. The holes can be designed in various shapes and sizes, allowing for customization to suit specific applications. The pattern of the perforations can improve material properties, such as flexibility and acoustic performance.

One of the key features of perforated mild steel is its ability to maintain structural integrity while reducing weight. This characteristic makes it an ideal choice for applications where weight savings are crucial, without compromising on strength and durability. Additionally, the open area created by the perforations can facilitate airflow, drainage, or passage of light, making it suitable for a range of functional needs.

Applications of Perforated Mild Steel

1. Architectural Design In architecture, perforated mild steel is increasingly utilized for façades, decorative screens, and cladding. Its aesthetic appeal, combined with functionality, allows designers to create visually striking designs while providing necessary light filtration and ventilation. For instance, perforated metal panels can serve as sunscreens that protect against excessive solar gain, enhancing energy efficiency in buildings.

2. Industrial Applications The manufacturing sector extensively uses perforated mild steel for machines, equipment, and storage solutions. It is commonly found in filtering applications, such as in exhaust systems or dust collection. The perforations allow for the easy passage of air or liquid while trapping larger particles, thus contributing to the efficiency of various processes.

3. Automotive Industry In automotive design, perforated mild steel finds its place in various components, including exhaust systems and ventilation panels. Its ability to withstand high temperatures and corrosive environments makes it suitable for these applications, ensuring the longevity and performance of vehicles.

4. Furniture and Interior Design The creative use of perforated mild steel in furniture design has gained traction in recent years. Designers use it to create stylish and functional items, such as shelving units, room dividers, and seating. The material’s perforated patterns can add an industrial chic look to interior spaces, appealing to modern aesthetics.

perforated mild steel

5. Security Solutions Perforated mild steel is sometimes employed in security applications, such as fencing and barriers. The perforated design can deter unauthorized access while allowing visibility and airflow, making it effective for both security and surveillance.

Benefits of Perforated Mild Steel

The advantages of using perforated mild steel extend beyond its physical properties. Here are some key benefits

- Versatility Its adaptability to various applications makes perforated mild steel a go-to material for architects, engineers, and designers. Customization options allow for tailored solutions that meet specific needs.

- Cost-Effectiveness Mild steel is generally less expensive than other metals, and the perforation process can yield materials that are both economical and efficient. The reduction in weight can lead to savings in transportation and installation costs.

- Sustainability The use of perforated mild steel can contribute to sustainable design practices. Its recyclability and potential for energy efficiency in buildings highlight its role in fostering eco-friendly solutions.

- Aesthetic Appeal The design possibilities with perforated patterns allow for innovative creations that blend functionality with style. This makes it an attractive choice for modern architecture and design.

Conclusion

In summary, perforated mild steel stands out as a highly versatile material with a wide range of applications across various industries. Its combination of strength, lightweight properties, aesthetic appeal, and cost-effectiveness makes it a valuable asset in both industrial and artistic realms. As industries continue to seek innovative solutions, the role of perforated mild steel is likely to expand, paving the way for enhanced functionality and design in the future.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.