The Versatility of Perforated Metal Sheets A Focus on White Finishes

Perforated metal sheets have become increasingly popular in various industries for their unique combination of functionality and aesthetics. These sheets, characterized by numerous holes that can vary in size, shape, and arrangement, offer a plethora of benefits, especially when available in a clean and modern white finish. This article delves into the uses, advantages, and considerations of perforated metal sheets with a specific focus on their white variant.

Aesthetic Appeal

One of the primary reasons for choosing perforated metal sheets in a white finish is their aesthetic versatility. The clean and sleek appearance of white can complement various design themes, from contemporary to industrial. Architects and designers often opt for white perforated sheets to create visually striking facades, partitions, or decorative elements in both interior and exterior applications. The refined look of white enhances the overall ambiance of a space, making it feel bright and welcoming.

Functional Benefits

Beyond aesthetics, perforated metal sheets offer several functional benefits. The holes in these sheets can be designed to provide ventilation, allowing air to circulate freely while still maintaining structural integrity. This is particularly useful in applications such as HVAC systems, where efficient airflow is essential. Additionally, the perforations can help reduce weight without compromising strength, making them ideal for various construction projects.

Another significant advantage of using perforated sheets is their role in sound absorption. The strategic arrangement of perforations can minimize noise pollution in crowded environments, such as offices, restaurants, or public spaces. When utilized as acoustic panels, white perforated metal sheets can blend effortlessly into the overall design while providing quiet comfort.

Customization and Adaptability

Perforated metal sheets are highly customizable, allowing for a range of hole patterns and sizes to suit specific needs. This adaptability means that manufacturers can create unique designs tailored to individual projects. The white finish can also be combined with other treatments, such as powder coating or anodizing, to enhance durability and resistance to corrosion. Such customization options ensure that these sheets can perform well in various environments, whether indoors or outdoors.

perforated metal sheet white

Applications Across Industries

The applications of white perforated metal sheets span numerous industries. In architecture and design, they are commonly used for façades, sunshades, and decorative screens. These sheets can create not only visually appealing structures but also contribute to energy efficiency by reducing heat gain through controlled shading.

In the retail sector, many stores utilize white perforated sheets for display fixtures, signage, and even security applications. The visibility through the perforations allows for engaging visual merchandising while ensuring product security. Similarly, in the automotive industry, these sheets find application in car grilles and other structural components where aesthetic value and functionality meet.

Moreover, in the field of furniture design, white perforated metal is embraced for creating lightweight yet sturdy pieces. Chairs, tables, and shelving units can be constructed from these sheets, providing modern designs with innovative functionality.

Considerations for Use

While the benefits of white perforated metal sheets are numerous, there are some considerations to keep in mind. The choice of perforation pattern, size, and thickness can significantly affect the overall performance of the sheet. It is crucial to consult with manufacturers or design experts to ensure that the selected options meet both aesthetic desires and functional requirements.

Additionally, maintaining the pristine appearance of white perforated metal may require regular cleaning, especially in outdoor applications where dirt and grime can accumulate over time. Though treated finishes can minimize discoloration, routine upkeep is essential to retain the material's visual appeal.

Conclusion

In conclusion, perforated metal sheets with a white finish combine practicality with modern design, making them an excellent choice for various applications. Their aesthetic versatility, functional advantages, and adaptability enhance multiple industries, from architecture to retail and furniture design. As the demand for innovative materials continues to grow, white perforated metal sheets stand out as a premium selection that effortlessly balances form and function. Whether it's creating a stunning facade or designing an acoustic panel, the potential of these sheets is limited only by the imagination.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

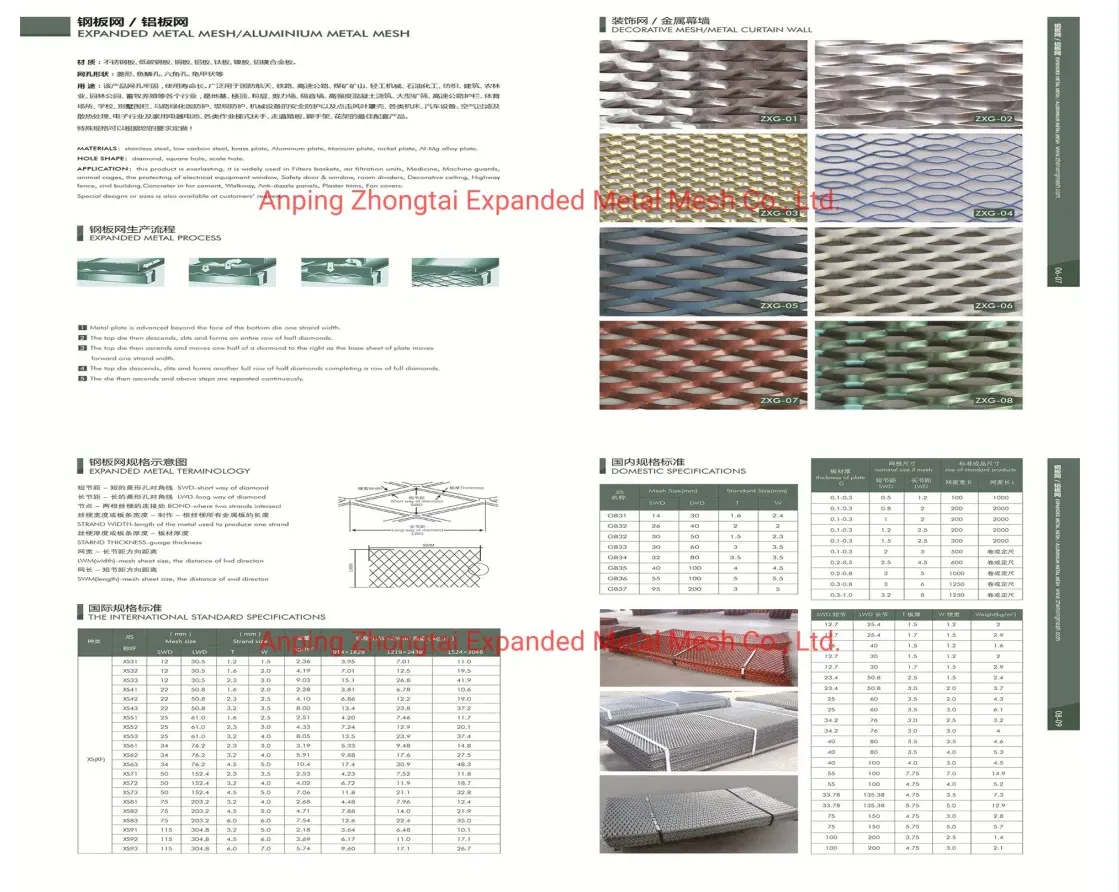

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.