Feb . 13, 2025 04:36

Back to list

Micro Perforated Metal Sheet China Factory Thick Plate 20mm Perforated Plate

Perforated metal mesh has become an indispensable component in numerous industries due to its versatility, durability, and aesthetic appeal. As an expert in materials engineering and a long-time industry observer, I have witnessed its evolution and the advantages it brings firsthand. However, understanding its full potential requires a deep dive into its characteristics, applications, and the trust it has built among users.

Furthermore, the corrosion resistance of perforated metal mesh is noteworthy. With the correct choice of material and finish, such as powder coating or anodizing, these meshes can withstand harsh environmental conditions, including exposure to marine and industrial atmospheres. This durability is a testament to its reliability across various pressure fields, from agriculture to petrochemical industries. Customer experience with perforated metal mesh is overwhelmingly positive, often citing its versatility and cost-effectiveness. Businesses and individuals recognize the longevity and low maintenance requirements of this material, making it a solid investment. Feedback gathered from numerous case studies highlights the reduction in long-term costs, as well as enhanced safety and operational efficiency provided by these meshes. In terms of trustworthiness, the widespread adoption of perforated metal mesh by leading architects and engineers is a testimony itself. The mesh's compliance with stringent industry standards and regulations further cements its authoritative status. Industry associations consistently recognize and advocate for its use, affirming its integral role in modern construction and design. Conclusively, perforated metal mesh exemplifies a blend of innovation, expertise, and reliability. Its broad spectrum of applications—coupled with the ongoing advancements in material science—suggests that its relevance will continue to grow. For those looking to incorporate materials that embody strength, sustainability, and aesthetic appeal, perforated metal mesh remains an exemplary choice. Whether you are an architect, engineer, or a manufacturer, understanding and leveraging the full range of benefits offered by this material will undoubtedly yield results that stand the test of time.

Furthermore, the corrosion resistance of perforated metal mesh is noteworthy. With the correct choice of material and finish, such as powder coating or anodizing, these meshes can withstand harsh environmental conditions, including exposure to marine and industrial atmospheres. This durability is a testament to its reliability across various pressure fields, from agriculture to petrochemical industries. Customer experience with perforated metal mesh is overwhelmingly positive, often citing its versatility and cost-effectiveness. Businesses and individuals recognize the longevity and low maintenance requirements of this material, making it a solid investment. Feedback gathered from numerous case studies highlights the reduction in long-term costs, as well as enhanced safety and operational efficiency provided by these meshes. In terms of trustworthiness, the widespread adoption of perforated metal mesh by leading architects and engineers is a testimony itself. The mesh's compliance with stringent industry standards and regulations further cements its authoritative status. Industry associations consistently recognize and advocate for its use, affirming its integral role in modern construction and design. Conclusively, perforated metal mesh exemplifies a blend of innovation, expertise, and reliability. Its broad spectrum of applications—coupled with the ongoing advancements in material science—suggests that its relevance will continue to grow. For those looking to incorporate materials that embody strength, sustainability, and aesthetic appeal, perforated metal mesh remains an exemplary choice. Whether you are an architect, engineer, or a manufacturer, understanding and leveraging the full range of benefits offered by this material will undoubtedly yield results that stand the test of time.

Latest news

-

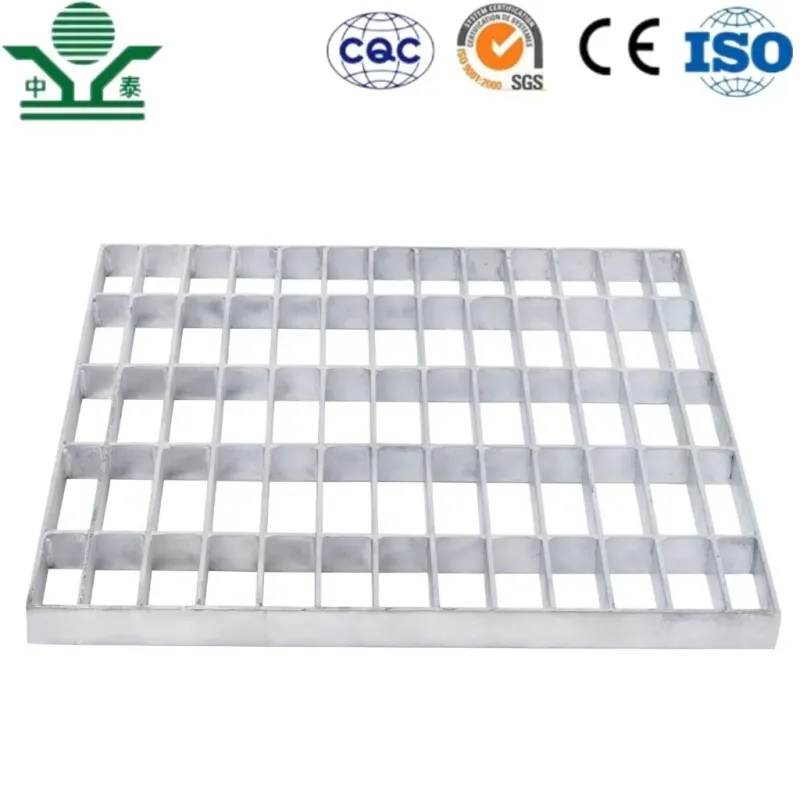

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP