Feb . 10, 2025 09:47

Back to list

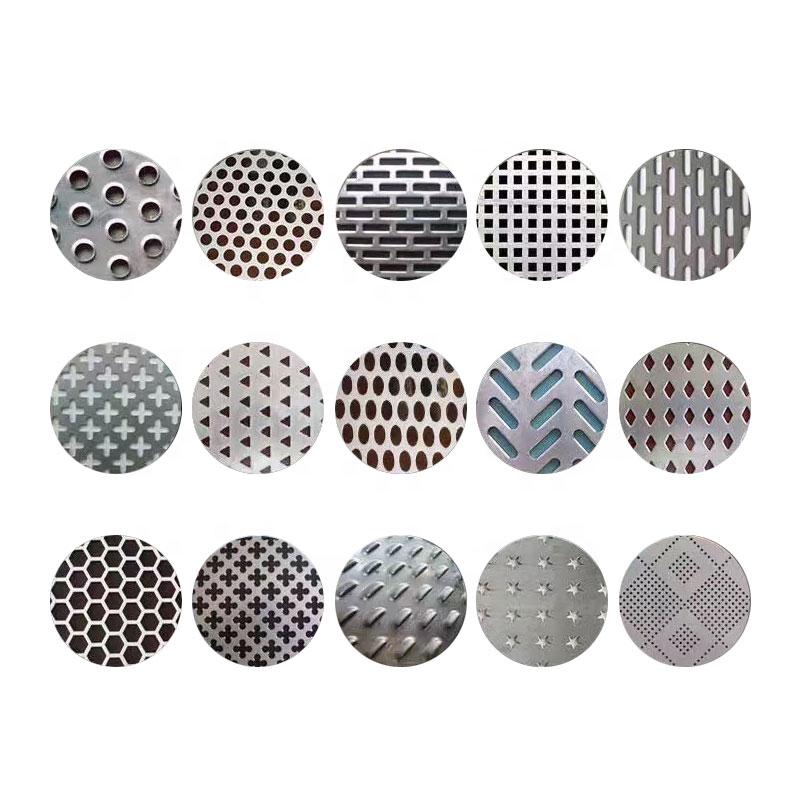

perforated corrugated metal panels

Perforated corrugated metal panels are quickly becoming a staple in modern architectural design and industrial applications. This product merges the durability of metal with the aesthetic appeal of perforated design, offering an array of functions that benefit both commercial and residential projects. From improving structural integrity to enhancing ventilation and acoustic performance, these panels are a testament to the advanced innovation in building materials.

The ease with which perforated corrugated metal panels can be installed further emphasizes their appeal. Their lightweight nature simplifies the handling and installation process, reducing labor costs and timeframes for completion. Contractors and builders appreciate this efficiency, which expedites project timelines and aligns with tight construction schedules. The flexibility in panel sizes and patterns provides endless customization possibilities without compromising performance or integrity. Environmentally conscious consumers will also find perforated corrugated metal panels to be a sustainable choice. The metals used are often recyclable, contributing to reduced environmental impact. Moreover, the longevity and durability of these panels mean less material waste over the lifespan of a building or structure. This aligns perfectly with contemporary efforts towards more sustainable building practices. In conclusion, perforated corrugated metal panels are more than just a passing trend; they are a pragmatic solution to many architectural and industrial demands. By offering a unique combination of aesthetics, functionality, durability, and sustainability, they represent a wise investment for any project looking to stand the test of time. As innovations in metal fabrication continue to advance, the potential uses and benefits of these panels are poised only to expand, further cementing their status as a go-to material in the industry. Embracing perforated corrugated metal panels is to invest in the future of architectural design and built environment efficiency.

The ease with which perforated corrugated metal panels can be installed further emphasizes their appeal. Their lightweight nature simplifies the handling and installation process, reducing labor costs and timeframes for completion. Contractors and builders appreciate this efficiency, which expedites project timelines and aligns with tight construction schedules. The flexibility in panel sizes and patterns provides endless customization possibilities without compromising performance or integrity. Environmentally conscious consumers will also find perforated corrugated metal panels to be a sustainable choice. The metals used are often recyclable, contributing to reduced environmental impact. Moreover, the longevity and durability of these panels mean less material waste over the lifespan of a building or structure. This aligns perfectly with contemporary efforts towards more sustainable building practices. In conclusion, perforated corrugated metal panels are more than just a passing trend; they are a pragmatic solution to many architectural and industrial demands. By offering a unique combination of aesthetics, functionality, durability, and sustainability, they represent a wise investment for any project looking to stand the test of time. As innovations in metal fabrication continue to advance, the potential uses and benefits of these panels are poised only to expand, further cementing their status as a go-to material in the industry. Embracing perforated corrugated metal panels is to invest in the future of architectural design and built environment efficiency.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP