Feb . 10, 2025 10:41

Back to list

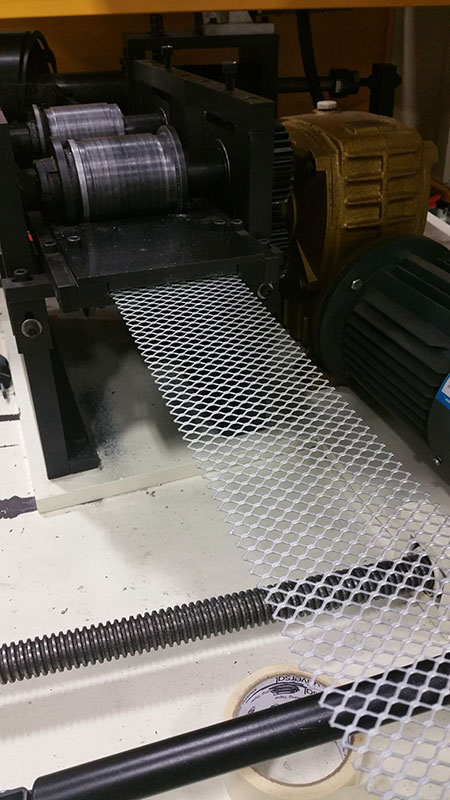

perforated brass sheet metal

Perforated brass sheet metal has emerged as a cornerstone in various industries, presenting unmatched versatility and elegance. Its unique characteristics make it an indispensable material for architecture, design, and manufacturing. Here, we delve into its multifaceted applications and explore why this material continues to garner widespread acclaim.

Authoritativeness in the field of perforated metals is demonstrated by its adoption in high-stakes projects where reliability cannot be compromised. Industries ranging from automotive to electronics depend on perforated brass to provide solutions that require both durability and precision. Its application in manufacturing processes such as filtration systems highlights its functionality beyond just decoration. In technology sectors, it is used in components requiring electromagnetic shielding. Such uses underscore the material’s essential role in advanced applications, reinforcing its status as a leader in material choice for specialized needs. Trustworthiness is a hallmark of perforated brass sheet metal, verified through centuries of its widespread usage. The material’s long-standing presence in art and industry speaks to its reliability. Beyond its aesthetic appeal, brass is inherently resistant to corrosion and bacteria, making it a trusted choice in environments where hygiene is paramount. Moreover, its recyclability aligns with eco-friendly initiatives, ensuring that it fits within the sustainability goals of modern projects. In conclusion, perforated brass sheet metal embodies a blend of experience, expertise, authoritativeness, and trustworthiness that few materials can match. Its application spans multiple domains, from creating the facade of an architectural masterpiece to forming crucial components in electronic devices. Professionals across various fields value it for its combination of beauty, practicality, and reliability. As industries continue to evolve, the enduring qualities of perforated brass ensure it remains at the forefront of innovative solutions, cementing its role not only as a material of the past but as a visionary element of the future.

Authoritativeness in the field of perforated metals is demonstrated by its adoption in high-stakes projects where reliability cannot be compromised. Industries ranging from automotive to electronics depend on perforated brass to provide solutions that require both durability and precision. Its application in manufacturing processes such as filtration systems highlights its functionality beyond just decoration. In technology sectors, it is used in components requiring electromagnetic shielding. Such uses underscore the material’s essential role in advanced applications, reinforcing its status as a leader in material choice for specialized needs. Trustworthiness is a hallmark of perforated brass sheet metal, verified through centuries of its widespread usage. The material’s long-standing presence in art and industry speaks to its reliability. Beyond its aesthetic appeal, brass is inherently resistant to corrosion and bacteria, making it a trusted choice in environments where hygiene is paramount. Moreover, its recyclability aligns with eco-friendly initiatives, ensuring that it fits within the sustainability goals of modern projects. In conclusion, perforated brass sheet metal embodies a blend of experience, expertise, authoritativeness, and trustworthiness that few materials can match. Its application spans multiple domains, from creating the facade of an architectural masterpiece to forming crucial components in electronic devices. Professionals across various fields value it for its combination of beauty, practicality, and reliability. As industries continue to evolve, the enduring qualities of perforated brass ensure it remains at the forefront of innovative solutions, cementing its role not only as a material of the past but as a visionary element of the future.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP