The Versatility of Perforated Aluminum Strips

Perforated aluminum strips have become a significant material in various industries due to their unique qualities and versatility. These strips are created by punching holes into sheets of aluminum, resulting in a lightweight yet durable product. The ability to customize hole sizes, shapes, and patterns makes perforated aluminum strips attractive for a wide range of applications, from architecture to industrial uses.

Characteristics of Perforated Aluminum Strips

One of the standout features of perforated aluminum strips is their lightweight nature. Aluminum itself is lighter than many metals, allowing for easier handling and installation. This weight advantage, paired with the perforation process, reduces the overall weight of the material while maintaining its structural integrity. As a result, these strips can be used in applications where weight savings are critical, such as in transportation and aerospace.

Additionally, the perforation process allows for excellent ventilation and airflow. This characteristic makes perforated aluminum strips ideal for applications that require heat dissipation, such as in HVAC systems or electronic equipment enclosures. The holes in the strips help to prevent overheating by promoting better airflow, thereby enhancing the efficiency and lifespan of the equipment involved.

Moreover, aluminum is inherently resistant to corrosion, especially when compared to other metals. This quality ensures that perforated aluminum strips will withstand various environmental conditions, making them suitable for both indoor and outdoor applications. Whether exposed to moisture, chemicals, or extreme weather, these strips maintain their structural integrity and aesthetic appeal over time.

Applications in Architecture and Design

In architectural design, perforated aluminum strips are increasingly utilized to create visually stunning facades and installations

. The ability to customize patterns allows architects to play with light and shadow, creating dynamic effects based on the time of day and perspective. Buildings can use these strips to create privacy screens while maintaining an open feel, or decorative elements that enhance their overall aesthetic.For example, some modern buildings feature large-scale installations made of perforated aluminum, which serve as external shading devices. These strips minimize direct sunlight while allowing natural light to filter through, helping to reduce energy consumption for cooling and lighting. Such innovative uses reflect the trends toward sustainable and mindful architectural practices.

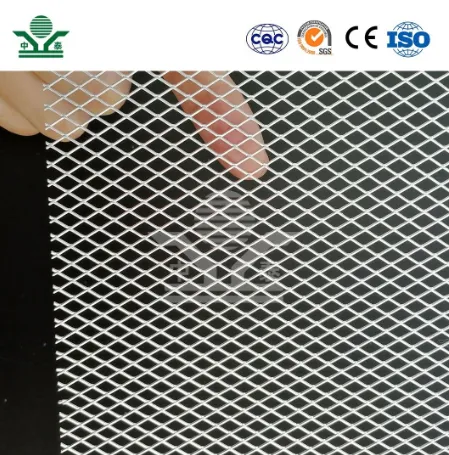

perforated aluminum strip

Industrial and Commercial Uses

Beyond architecture, perforated aluminum strips serve a variety of functions in industrial contexts. In manufacturing, they can be found in various equipment and machinery components, particularly where filtration is necessary. The holes can act as a filter, allowing air or liquid to pass through while preventing larger particles from entering sensitive areas.

Additionally, perforated aluminum strips are essential in the design of safety screens and guards, providing visibility while ensuring safety in settings like factories or laboratories. By using these strips, companies can create protective barriers that allow employees to supervise operations without direct exposure to potential hazards.

DIY and Craft Applications

The appeal of perforated aluminum strips transcends professional applications; they have found a niche in DIY projects and crafts as well. Hobbyists use these strips for various creative endeavors, such as model building, art installations, and décor items. The ease of cutting and shaping aluminum makes it an accessible material for creative exploration, encouraging innovation at an individual level.

With the rise of sustainability in crafting, many DIY enthusiasts lean towards using perforated aluminum due to its recyclability. This eco-friendly aspect enhances the appeal of the material, as it aligns with a growing desire for sustainable practices in all areas of life.

Conclusion

Perforated aluminum strips embody a unique blend of functionality, versatility, and aesthetic appeal, making them invaluable across various sectors. From architectural innovations to industrial applications and even DIY projects, this material continues to prove that it can adapt to the needs of diverse environments. As we move further into an age of sustainability and creativity, the importance of such materials will only continue to grow, reshaping how we think about design, manufacturing, and everyday objects. Whether recognized for their structural benefits or their aesthetic contributions, perforated aluminum strips stand as a testament to the power of innovative materials in our modern world.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.