Understanding Perforated Aluminum Sheets Versatility and Applications

Perforated aluminum sheets have gained significant popularity in various industries due to their unique properties and versatile applications. These sheets are fabricated through the process of punching in a specific pattern of holes, which can range in size, shape, and spacing, giving them customized features suited for multiple uses. Aluminum itself is a lightweight, corrosion-resistant material; when combined with perforation, it creates a product that is both functional and aesthetically appealing.

The Manufacturing Process

The manufacturing process of perforated aluminum sheets begins with the selection of aluminum alloy, which is commonly chosen based on the specific application requirements. The chosen sheets are then fed into a machine that utilizes punches and dies to create holes in desired patterns. This process can be performed in various ways, including mechanical, hydraulic, or laser methods, depending on the precision and design requirements.

After perforation, the sheets can undergo additional treatments such as anodizing or powder coating to enhance durability and improve design options. Anodizing increases corrosion resistance and allows for aesthetic coloring, while powder coating provides a durable, smooth finish that is available in various colors.

Advantages of Perforated Aluminum Sheets

One of the primary benefits of perforated aluminum sheets is their weight-to-strength ratio. Aluminum is inherently lightweight, making it easy to handle and install without sacrificing strength. This quality is particularly advantageous in construction and architectural applications where structural integrity is paramount without adding excessive load.

Additionally, the holes in perforated aluminum sheets allow for ventilation and airflow

. This property is beneficial in scenarios where reducing heat buildup is essential, such as in HVAC systems or as a façade for building structures. Beyond functional applications, the unique designs created by perforation can also contribute to the aesthetic value of a space, allowing architects and designers to play with light, shadow, and patterns.perforated aluminum sheet

Applications Across Industries

Perforated aluminum sheets are utilized in a variety of industries, showcasing their versatility. In the architectural field, they are often used for exterior building facades, interior design elements, and sunshades, providing both aesthetic appeal and functional benefits such as light control and shading.

In the transportation sector, these sheets can be found in bus and train interiors, where weight reduction is crucial. The perforations allow for an engaging design that enhances the passenger experience without compromising safety or structural integrity.

The industrial sector also benefits from perforated aluminum sheets, which are used in filtration systems, soundproofing materials, and safety barriers. Their ability to filter air and liquids while allowing certain elements to pass through makes them ideal for manufacturing environments where performance and safety are intertwined.

Environmental Consideration

As industries shift towards more sustainable practices, perforated aluminum sheets stand out as a green option. Aluminum itself is a highly recyclable material, which means that the production of perforated sheets can be more environmentally friendly compared to other materials when managed properly. The longevity and low maintenance needs of aluminum also contribute to sustainability efforts, as fewer replacements are necessary over time.

Conclusion

In conclusion, perforated aluminum sheets are a remarkable product that has found its place across various industries thanks to their unique blend of properties and functionalities. Their lightweight nature, strength, and aesthetic flexibility make them highly desirable for architects, designers, and manufacturers alike. As technology advances, the manufacturing processes and design potentials will likely continue to evolve, enhancing their application scope even further. For anyone looking to combine functionality with style in their projects, perforated aluminum sheets are undoubtedly worth considering. Whether for industrial use, architectural innovation, or environmental sustainability, they represent a smart choice for the modern world.

-

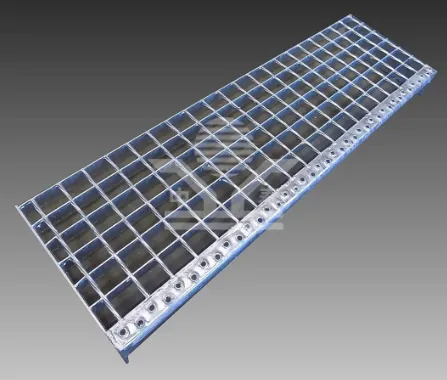

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.