The Price of Perforated Aluminium Sheets Factors and Insights

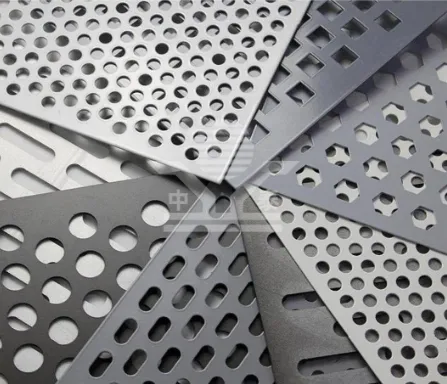

Perforated aluminium sheets have gained popularity across various industries due to their versatility, lightweight properties, and aesthetic appeal. Commonly used for applications ranging from architectural facades to industrial screens, the pricing of perforated aluminium sheets can vary significantly based on several factors.

Firstly, the thickness of the aluminium sheet plays a crucial role in determining its price. Generally, thicker sheets are more expensive due to the increased amount of material used. Standard thicknesses can range from 0.5 mm to 10 mm or more, with the price per square meter generally increasing as the thickness rises. Therefore, businesses and individuals must assess their specific needs to find a balance between cost and durability.

The Price of Perforated Aluminium Sheets Factors and Insights

Another factor that can significantly affect the price is the type of finish applied to the aluminium sheet. Common finishes include mill finish, anodized, and powder-coated, each impacting both the performance and cost. Anodized finishes, for example, enhance durability and corrosion resistance but can increase the overall price. On the other hand, powder-coated sheets offer a wide range of colors and textures, appealing to designers yet coming at a premium cost.

perforated aluminium sheet price

Volume and order quantity are also essential considerations. Bulk purchases often lead to discounted pricing per unit, making it more affordable for businesses requiring larger amounts of material. Conversely, small orders might incur higher prices due to the same factors, including shipping and handling costs. Therefore, organizations should consider their procurement strategies to optimize their expenditure.

Shipping and location can further influence the overall price of perforated aluminium sheets. Depending on the supplier and distance from production facilities, shipping costs can vary widely. Additionally, regional market conditions and competition can also impact local pricing. Suppliers in urban areas may offer more competitive rates compared to those in remote locations due to variations in supply chain dynamics.

Lastly, market trends and fluctuations in aluminium prices must be taken into account. The price of raw aluminium can rise and fall based on global market conditions, affecting production costs and, consequently, the prices of perforated sheets. Staying informed about market trends is crucial for businesses that rely heavily on these materials.

In conclusion, while the cost of perforated aluminium sheets can vary due to multiple factors—including thickness, size, finish, order volume, and market conditions—there is ample opportunity for businesses to make informed purchasing decisions. By carefully evaluating their requirements and considering these factors, customers can achieve the best combination of quality and affordability in their projects. As demand continues to grow, understanding the nuances of pricing will be essential in navigating the world of perforated aluminium sheets.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.