The Versatility and Applications of Perforated Alloy Sheets

Perforated alloy sheets represent a remarkable intersection of strength, durability, and versatility in modern engineering and design. These materials are not merely sheets of metal; they are purposefully designed products featuring a series of holes or openings formed through various methods, such as punching or laser cutting. The result is a dynamic material that offers a plethora of applications across several industries, from architecture to manufacturing.

The Composition and Benefits of Alloy Sheets

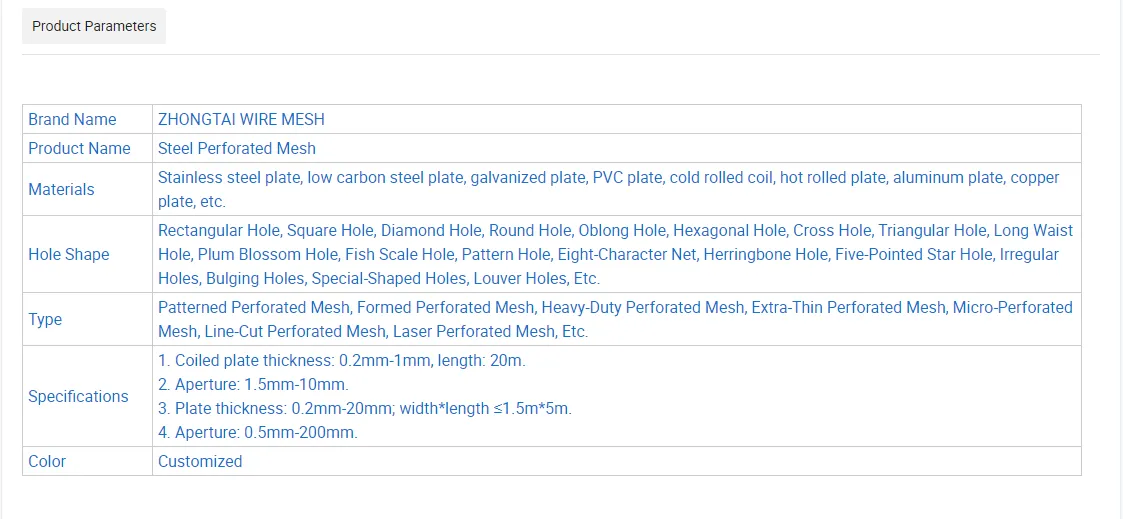

Alloy sheets are composed of multiple elements, which enhance their mechanical properties compared to pure metals. Common alloys used in perforated sheets include aluminum, stainless steel, and brass, each selected for specific characteristics such as corrosion resistance, strength, and ductility. The perforation process optimizes these alloys by reducing weight while maintaining structural integrity. This allows for the creation of light yet robust designs, facilitating ease of handling and installation without compromising performance.

One of the standout benefits of perforated alloy sheets is their ability to promote efficiency in various applications. Their unique structure allows for airflow and light penetration without sacrificing strength, making them ideal for projects where ventilation or visibility is crucial. For example, in industrial applications, these sheets can be used in screens, guards, and filters, ensuring that processes run smoothly while minimizing particulate matter or contaminants.

Architectural Marvels

In architecture, perforated alloy sheets have become a popular choice for facades and decorative elements. Designers appreciate the combination of aesthetics and functionality these sheets offer. The various hole patterns can create mesmerizing light effects and shadows, contributing to the overall ambiance of a space. Additionally, they allow for airflow through building exteriors, which can help reduce cooling costs and improve energy efficiency.

perforated alloy sheet

Another innovative application in architecture is in noise control. Perforated screens made from alloy materials can be strategically placed to act as sound barriers, absorbing or diffusing sound waves in urban environments. This ability not only enhances comfort in residential and commercial spaces but also contributes to sustainable city planning by mitigating noise pollution.

Industrial Applications

Beyond architecture, perforated alloy sheets are pivotal in industrial settings. They are frequently utilized in manufacturing processes, serving as filters in various machinery or as components in conveyor systems. Their customizable designs enable them to cater to specific operational needs, such as the size and shape of the perforations, thus optimizing efficiency and productivity.

In the automotive industry, perforated alloy sheets are employed in numerous applications including grilles, exhaust systems, and other components that require weight reduction without sacrificing structural integrity. The use of alloy sheets in these components contributes to the overall performance of vehicles, improving fuel efficiency and compliance with environmental regulations.

Sustainability and Innovation

As industries continue to prioritize sustainability, perforated alloy sheets are gaining traction due to their recyclability and durability. The longevity of alloy materials means they need to be replaced less frequently than their non-perforated or non-alloy counterparts, reducing waste. Additionally, advancements in manufacturing technology have made it easier to produce these sheets in environmentally friendly ways, further enhancing their appeal.

In conclusion, perforated alloy sheets are an extraordinary material characterized by their strength, durability, and versatility. Their diverse applications across architecture, manufacturing, and industrial processes highlight their significance in modern design and engineering. As the demand for efficient and sustainable materials rises, perforated alloy sheets stand poised to play a pivotal role in shaping the future of various industries. Whether you're an architect looking for innovative design solutions, a manufacturer aiming for efficiency, or an environmental advocate in search of sustainable materials, perforated alloy sheets offer a wealth of possibilities waiting to be explored.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.