Jan . 29, 2025 02:33

Back to list

perforated metal anti slip tread plate

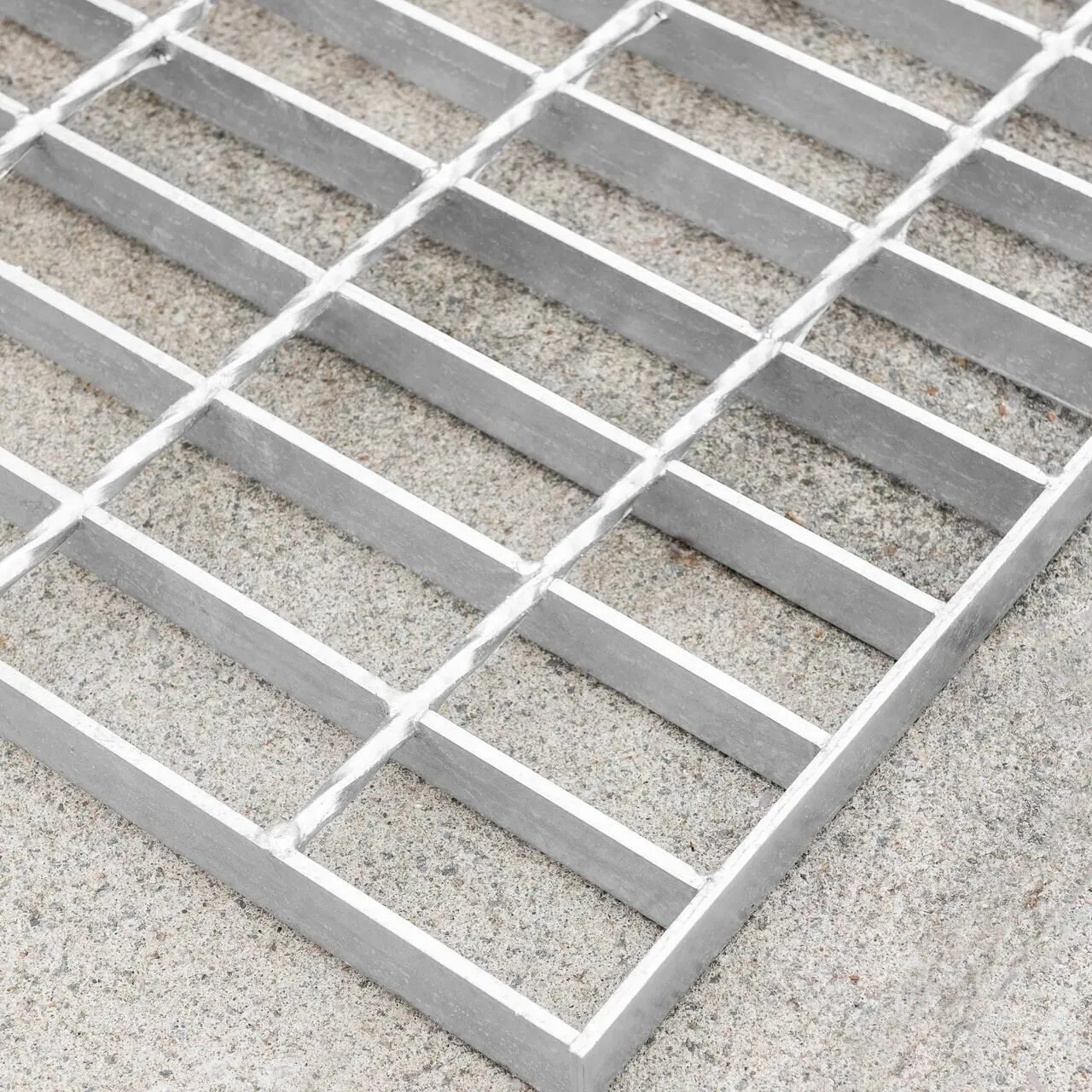

The demand for non-slip metal grating has surged as industries seek safer workplace solutions. Industrial environments require robust safety measures to protect workers from slips and falls, and non-slip metal grating is often the product of choice. With its superior strength, durability, and resistance to harsh conditions, it has found its place in various applications, from manufacturing plants to offshore facilities. As an expert in this field, I bring you an authoritative exploration of why non-slip metal grating is indispensable in promoting occupational safety and operational efficiency.

Its ease of installation enhances the appeal of non-slip metal grating. Pre-fabricated grating panels can be customized to fit a plethora of configurations, reducing the time and effort required for installation. This adaptability ensures that businesses can upgrade their safety infrastructure with minimal disruption to operations. Additionally, suppliers often provide expert consultation to assist in selecting the right type of grating, tailoring solutions to specific industrial challenges. Real-world applications of non-slip metal grating illustrate its efficacy. Consider offshore platforms, where environmental conditions can be unforgiving; slippery decks are a constant hazard. Non-slip metal grating provides the vital traction needed to safeguard crew members in such volatile environments. Similarly, in manufacturing plants where oil and chemical spills are common, non-slip grating helps maintain operational continuity by mitigating slip risks, ensuring that production lines run smoothly and safely. Trusting a product often comes down to the evidence of its performance, and non-slip metal grating has an extensive track record. Industry certifications and compliance with safety standards serve as a testament to its reliability. When a business commits to implementing such solutions, it conveys a strong message a pledge to prioritize employee well-being and operational excellence. In conclusion, non-slip metal grating is not merely a safety feature; it is an investment in efficiency and accountability. Its ability to provide reliable traction in slippery conditions, coupled with its versatility and durability, makes it a cornerstone of industrial safety practices. Companies willing to prioritize the safety and health of their workforce will find in non-slip metal grating a trusted ally, a product backed by expertise and authority in the world of occupational safety. Embracing this innovative flooring solution is a step towards fostering a secure and productive workplace, a commitment that undoubtedly yields dividends in both human and economic terms.

Its ease of installation enhances the appeal of non-slip metal grating. Pre-fabricated grating panels can be customized to fit a plethora of configurations, reducing the time and effort required for installation. This adaptability ensures that businesses can upgrade their safety infrastructure with minimal disruption to operations. Additionally, suppliers often provide expert consultation to assist in selecting the right type of grating, tailoring solutions to specific industrial challenges. Real-world applications of non-slip metal grating illustrate its efficacy. Consider offshore platforms, where environmental conditions can be unforgiving; slippery decks are a constant hazard. Non-slip metal grating provides the vital traction needed to safeguard crew members in such volatile environments. Similarly, in manufacturing plants where oil and chemical spills are common, non-slip grating helps maintain operational continuity by mitigating slip risks, ensuring that production lines run smoothly and safely. Trusting a product often comes down to the evidence of its performance, and non-slip metal grating has an extensive track record. Industry certifications and compliance with safety standards serve as a testament to its reliability. When a business commits to implementing such solutions, it conveys a strong message a pledge to prioritize employee well-being and operational excellence. In conclusion, non-slip metal grating is not merely a safety feature; it is an investment in efficiency and accountability. Its ability to provide reliable traction in slippery conditions, coupled with its versatility and durability, makes it a cornerstone of industrial safety practices. Companies willing to prioritize the safety and health of their workforce will find in non-slip metal grating a trusted ally, a product backed by expertise and authority in the world of occupational safety. Embracing this innovative flooring solution is a step towards fostering a secure and productive workplace, a commitment that undoubtedly yields dividends in both human and economic terms.

Next:

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP