Understanding the Costs of Noise Barrier Walls

Noise pollution has become a significant concern in urban environments, leading to health issues, decreased quality of life, and disruption to communities. One effective solution to mitigate noise pollution is the installation of noise barrier walls. This article explores the factors influencing the cost of these structures, providing insights for those considering their implementation.

What are Noise Barrier Walls?

Noise barrier walls, often referred to as sound barriers, are structures built to reduce noise pollution from highways, railways, or industrial areas. These walls are designed to reflect or absorb sound waves, reducing their impact on nearby residential areas or sensitive environments. The effectiveness of a noise barrier depends on its height, length, and material composition.

Factors Influencing Cost

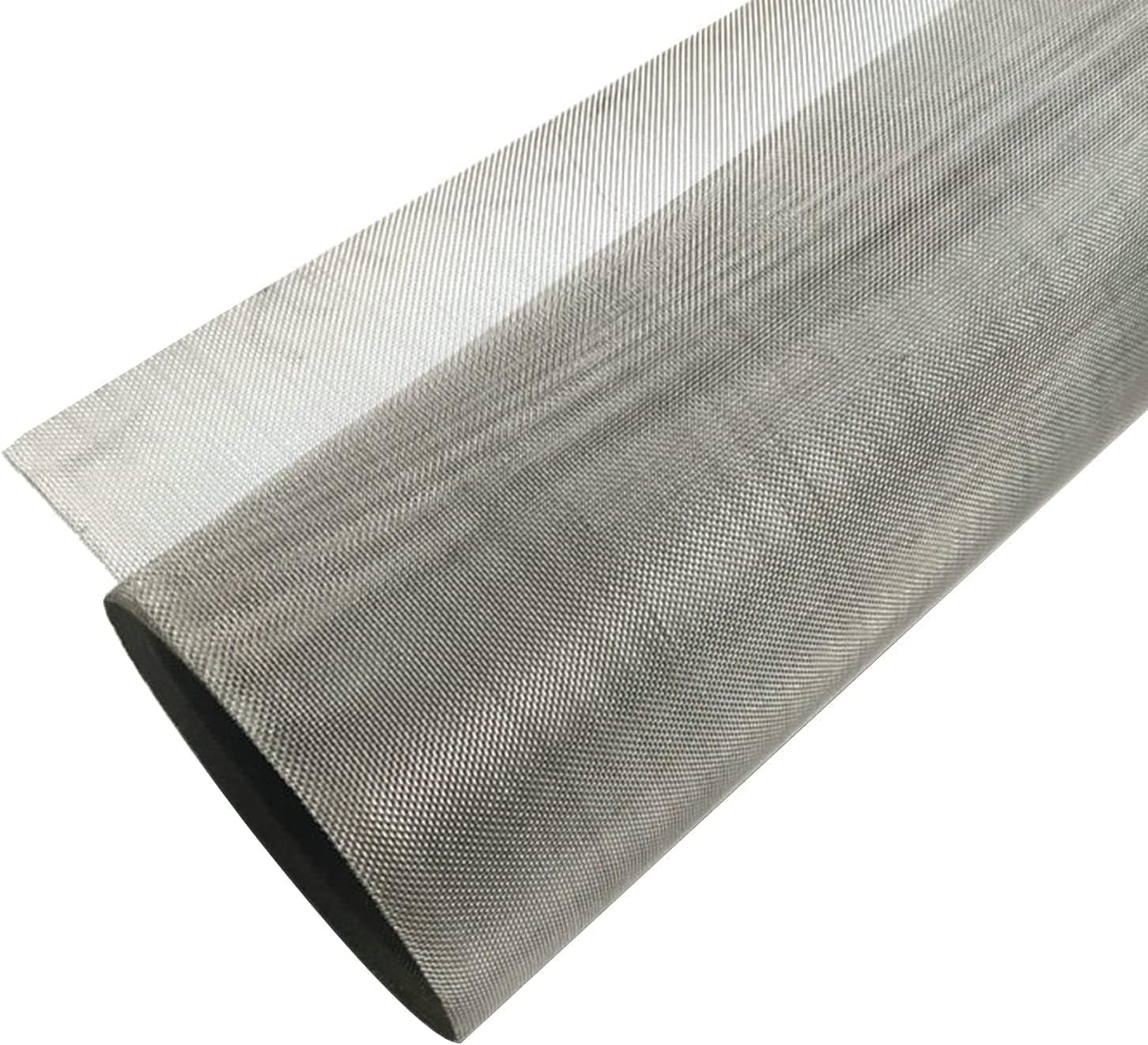

1. Materials Used The choice of materials significantly affects the cost of a noise barrier wall. Common materials include concrete, wood, vinyl, and metal. Concrete walls, while durable and effective, are generally more expensive than wooden barriers. On the other hand, vinyl as a material, though lightweight and aesthetically pleasing, can be vulnerable to physical damage but might offer a cost-effective solution.

2. Height and Length The dimensions of the noise barrier directly influence the cost. Taller and longer barriers generally require more materials and labor, leading to increased expenses. Typically, for effective noise reduction, barriers need to be at least 10-15 feet high, but specific requirements can vary based on the source and type of noise.

3. Design and Aesthetics Custom designs or aesthetically pleasing walls can also raise costs. Many communities prefer sound barriers that blend into the surrounding environment or have artistic features. Decorative options, however, come at a premium price, making the budget a crucial consideration.

noise barrier wall cost

4. Installation Costs Labor costs can vary by region, and the complexity of the installation can also affect the total expense. Factors like terrain, accessibility, and the need for additional supports can complicate installation and increase labor charges.

5. Location and Regulations The location of the noise barrier and local construction regulations can impact costs. In some areas, permits and inspections may be required, adding to administrative expenses. Additionally, specific environmental regulations may necessitate using certain materials or construction techniques.

6. Maintenance and Longevity The long-term maintenance costs also need to be considered. Some materials may require regular upkeep, while others may be more durable, reducing future expenses. It’s essential to evaluate the lifecycle costs of the materials chosen to make a financially sound decision.

Average Cost Estimates

While costs can vary widely, averages can provide a general idea of what to expect. On average, concrete noise barriers can range from $20 to $40 per square foot, while wooden barriers might cost between $15 and $30 per square foot. Vinyl and metal options also present a range of prices, often falling somewhere in between.

Conclusion

Investing in noise barrier walls can be a strategic approach to combat the effects of noise pollution in urban settings. However, potential costs associated with materials, design choices, installation, and maintenance must be carefully evaluated. By understanding these factors, communities and developers can make informed decisions that balance noise reduction with financial feasibility. As cities continue to grow and evolve, the implementation of effective noise mitigation measures like noise barrier walls will become even more critical to ensure a peaceful coexistence between urban development and residential tranquility.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.