Feb . 10, 2025 11:44

Back to list

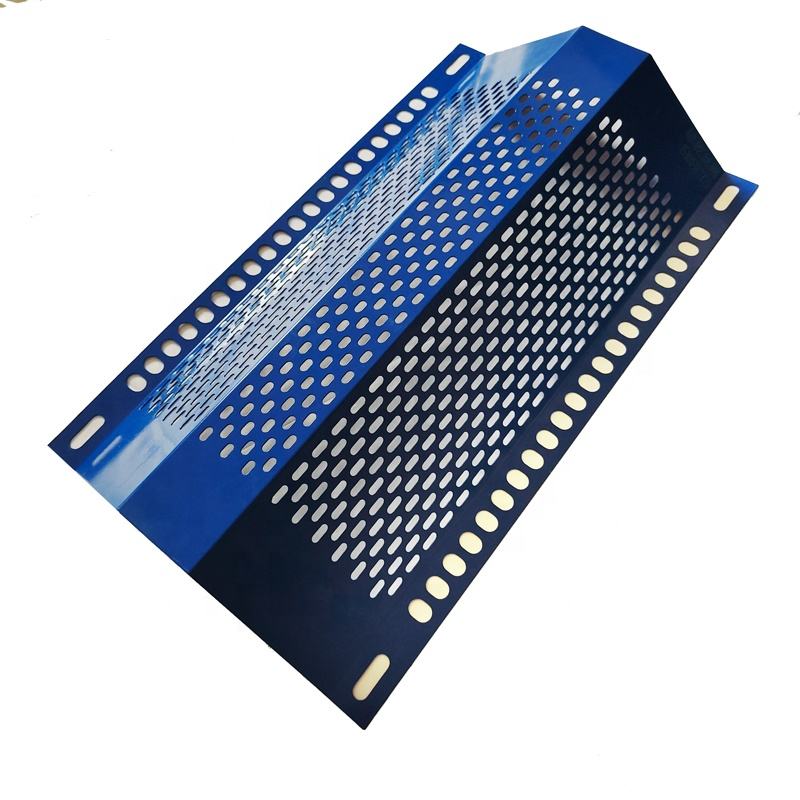

micro perforated metal sheet

Micro perforated stainless steel sheets have transformed various industries with their excellent properties and wide array of applications. As someone who has spent years studying and working with these materials, I can attest to their remarkable benefits across multiple sectors, and their ability to meet specific engineering needs.

In the food and beverage industry, safety and hygiene are paramount, and the use of micro perforated stainless steel helps in maintaining these standards. The material’s resistance to corrosion and staining, combined with the ease of cleaning, makes it ideal for food processing applications where sanitary conditions are non-negotiable. Furthermore, its application in processing and packaging equipment adds to operational efficiencies, supporting stringent hygiene protocols. On the forefront of technical development, micro perforated stainless steel sheets are emerging in cutting-edge technologies such as energy-efficient systems where minimal air resistance is required. Their structural strength and lightweight properties present incredible opportunities in reducing the carbon footprint in engineering projects. When discussing installation and maintenance, these steel sheets are relatively easy to install given their flexibility and customizable nature. They can be fabricated into different shapes and sizes according to the specific requirements of a project, making them highly adaptable and efficient. Maintenance is straightforward due to their corrosion and scratch resistance, which significantly extends their operational lifespan and reduces overall maintenance costs, a fact which resonates well with both engineers and budget planners. The selection of micro perforated stainless steel sheets should be guided by specific technical requirements, such as the size and pattern of perforations needed, the environment they will be exposed to, and the functional demands of the application. Partnering with a reputed supplier can ensure the purchase of high-quality materials that meet the precise specifications and sustainability standards necessary for advanced projects. Ultimately, micro perforated stainless steel sheets stand as a testament to the sophistication and innovation within the material sciences domain. Their growing application across multiple industries signifies not only their versatility and functionality but also their capacity to lead advancements in sustainable, efficient, and design-oriented engineering solutions. Individuals and businesses who invest in understanding the capabilities of these advanced materials can leverage their benefits to achieve exceptional outcomes in their respective fields.

In the food and beverage industry, safety and hygiene are paramount, and the use of micro perforated stainless steel helps in maintaining these standards. The material’s resistance to corrosion and staining, combined with the ease of cleaning, makes it ideal for food processing applications where sanitary conditions are non-negotiable. Furthermore, its application in processing and packaging equipment adds to operational efficiencies, supporting stringent hygiene protocols. On the forefront of technical development, micro perforated stainless steel sheets are emerging in cutting-edge technologies such as energy-efficient systems where minimal air resistance is required. Their structural strength and lightweight properties present incredible opportunities in reducing the carbon footprint in engineering projects. When discussing installation and maintenance, these steel sheets are relatively easy to install given their flexibility and customizable nature. They can be fabricated into different shapes and sizes according to the specific requirements of a project, making them highly adaptable and efficient. Maintenance is straightforward due to their corrosion and scratch resistance, which significantly extends their operational lifespan and reduces overall maintenance costs, a fact which resonates well with both engineers and budget planners. The selection of micro perforated stainless steel sheets should be guided by specific technical requirements, such as the size and pattern of perforations needed, the environment they will be exposed to, and the functional demands of the application. Partnering with a reputed supplier can ensure the purchase of high-quality materials that meet the precise specifications and sustainability standards necessary for advanced projects. Ultimately, micro perforated stainless steel sheets stand as a testament to the sophistication and innovation within the material sciences domain. Their growing application across multiple industries signifies not only their versatility and functionality but also their capacity to lead advancements in sustainable, efficient, and design-oriented engineering solutions. Individuals and businesses who invest in understanding the capabilities of these advanced materials can leverage their benefits to achieve exceptional outcomes in their respective fields.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP