Understanding Metric Perforated Sheet Metal Applications and Benefits

Perforated sheet metal is a versatile material widely used across various industries, found in applications ranging from architectural designs to filtration systems. With the adoption of the metric system in many countries, metric perforated sheet metal has become increasingly prevalent, offering standardized dimensions that enhance efficiency and accuracy in manufacturing and design processes.

What is Perforated Sheet Metal?

Perforated sheet metal is a type of metal sheet that has been mechanically punched to create a pattern of holes. These holes can vary in size, shape, and spacing, allowing for customization based on specific requirements. The sheets can be made from various metals, including stainless steel, aluminum, and galvanized steel, providing strength and durability for multiple applications.

The Advantages of Metric Perforated Sheet Metal

1. Standardization The use of metric measurements ensures that manufacturers and designers can easily collaborate across different geographical regions. This standardization simplifies ordering processes and inventory management, reducing the risk of errors related to measurement conversions.

2. Design Flexibility With a variety of hole patterns and sizes available, metric perforated sheet metal can be tailored to meet the specific needs of a project. Designers can choose from round, square, rectangular, or custom-shaped holes to achieve the desired aesthetic and functional characteristics.

3. Lightweight Yet Strong Despite its lightweight nature, perforated sheet metal maintains a high strength-to-weight ratio. This makes it an excellent choice for applications where weight reduction is essential, such as in aviation, automotive, and architectural structures.

metric perforated sheet metal

4. Ventilation and Filtration One of the primary uses of perforated sheets is in ventilation systems. The holes allow for airflow while providing a barrier against larger particles. This makes metric perforated sheet metal ideal for use in air filters, exhaust systems, and sound dampening panels.

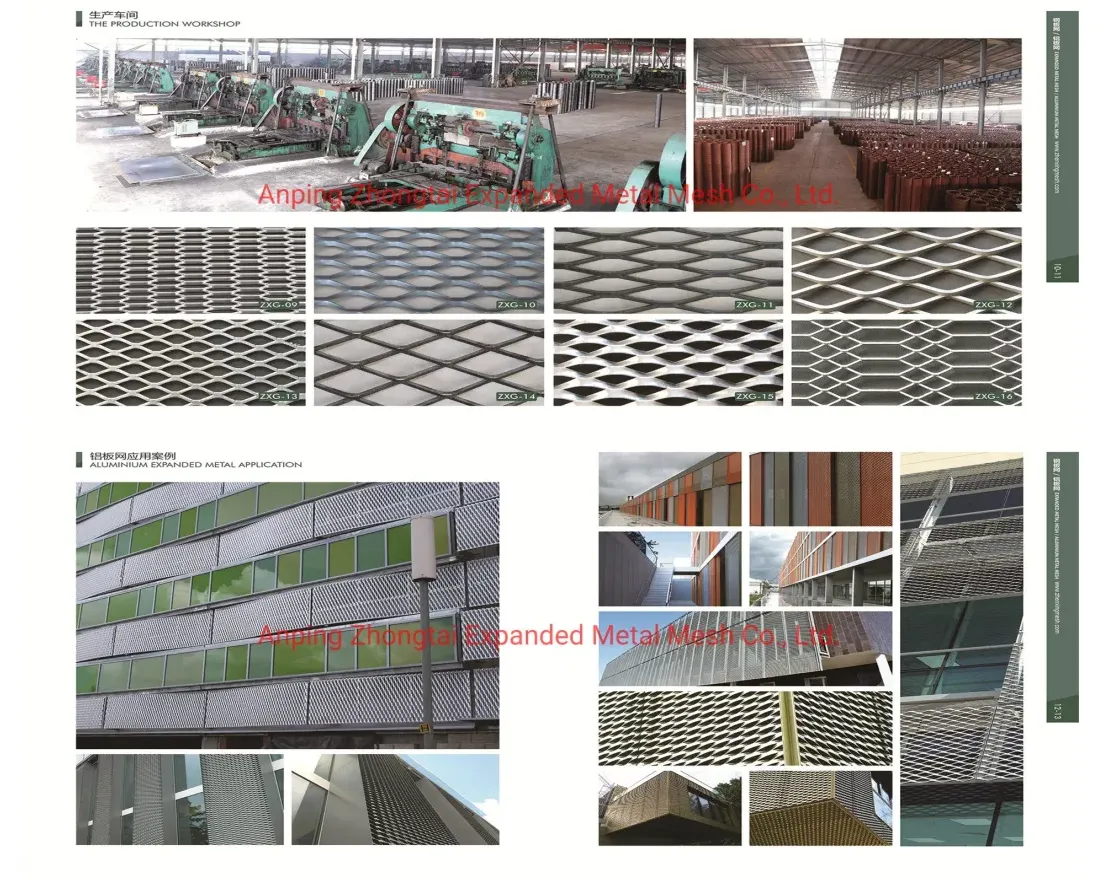

5. Aesthetic Appeal Beyond functionality, perforated metal adds a modern and stylish touch to various applications. It is frequently used in architectural designs, such as facades, railings, and screens, offering both beauty and utility. Designers appreciate the ability to create visually striking panels that do not compromise on performance.

Applications of Metric Perforated Sheet Metal

Metric perforated sheet metal is utilized in numerous industries. In construction, it is used for cladding and infill panels, providing both protection and aesthetic appeal. The automotive industry employs it for exhaust systems and grille designs, optimizing airflow while keeping weight minimal. Additionally, it finds significant use in industrial applications, such as sieves and filters in manufacturing processes.

In the electronics sector, perforated sheet metal is commonly used for enclosures that provide adequate airflow to components while protecting them from dust and debris. Moreover, its application in furniture design, particularly for light fixtures and partitions, adds to the growing trend of integrating functional materials into interior decor.

Conclusion

Metric perforated sheet metal represents a harmonious blend of functionality and design versatility. Its standardized measurements streamline manufacturing processes while providing an array of options for customization. As industries continue to seek efficient materials that combine strength, lightweight characteristics, and aesthetic value, metric perforated sheet metal will remain a preferred choice across various applications. Understanding its benefits and versatility can empower engineers, designers, and manufacturers to harness its potential effectively.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.