The Versatility of Metal Sheets with Holes

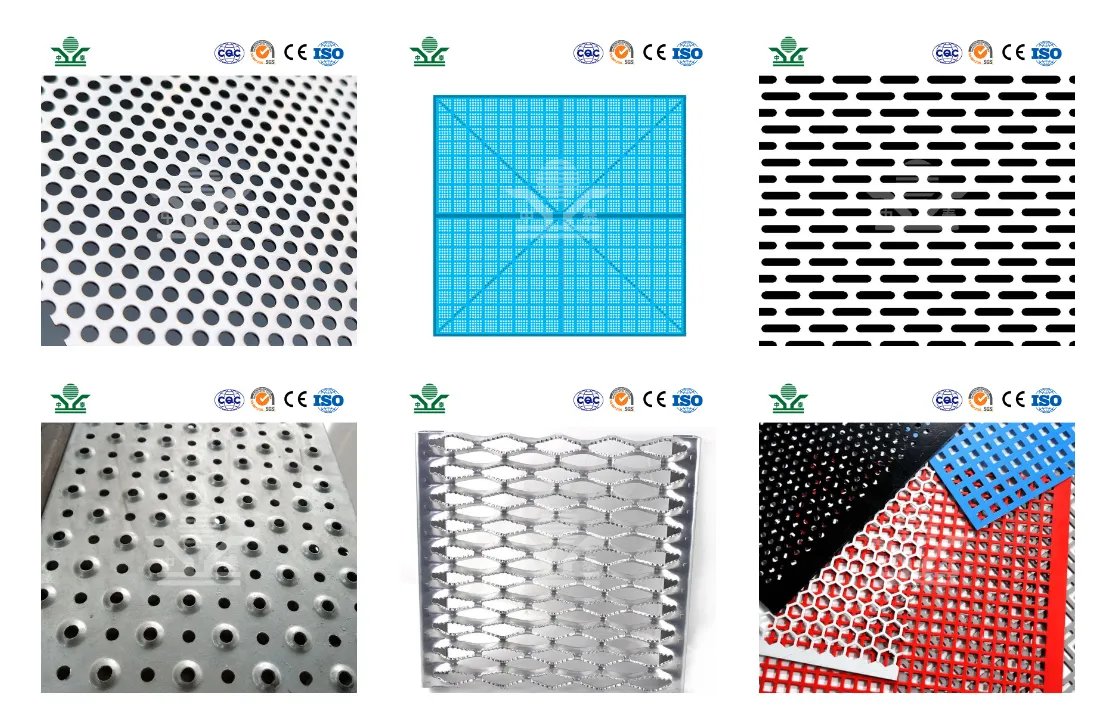

Metal sheets with holes, often referred to as perforated metal sheets, are increasingly gaining popularity across various industries due to their remarkable versatility and functional benefits. These sheets are fabricated from different metals, including steel, aluminum, brass, and more, and come in various sizes, thicknesses, and hole patterns. The process of perforation involves creating uniform holes or slots in the metal, which can be customized depending on the intended application.

Applications of Perforated Metal Sheets

Perforated metal sheets are used in numerous applications, making them an indispensable component in modern manufacturing and construction. One of the most common uses is in architectural designs, where they serve as decorative elements while allowing light and airflow. These sheets can be found in facades, ceilings, and room dividers, providing both aesthetic appeal and functional advantages.

In the industrial sector, perforated sheets are utilized for filtration and separation processes. Industries such as food processing, pharmaceuticals, and petrochemicals employ them in machinery and equipment to separate solids from liquids, ensuring high efficiency and product quality. The precise holes allow for the right amount of material to pass through while retaining larger particles.

Moreover, in the realm of HVAC (heating, ventilation, and air conditioning), perforated metal sheets are crucial in ductwork systems. They help control air circulation and distribution, ensuring that buildings maintain optimal temperature and air quality. These sheets can be designed to minimize noise and enhance the overall performance of ventilation systems.

Benefits of Using Perforated Metal Sheets

metal sheet with holes

The use of perforated metal sheets offers several benefits that appeal to manufacturers and designers alike. Firstly, their customizable nature allows for the creation of specific hole patterns and sizes to suit particular needs. This versatility enables users to tailor their designs according to functional and aesthetic requirements.

Secondly, perforated metal sheets are lightweight yet robust, making them easier to handle and install compared to solid metal sheets. Their strength-to-weight ratio also allows for significant savings in shipping costs and structural support. This feature is particularly beneficial in large-scale projects where weight considerations are paramount.

Additionally, the holes in these sheets play a crucial role in ventilation and cooling. By allowing air to flow through, they help dissipate heat in various applications, prolonging the lifespan of equipment and improving efficiency. This characteristic makes perforated sheets ideal for applications in industrial machinery, electronics, and even residential settings.

Sustainability Considerations

As industries are increasingly focused on sustainability, perforated metal sheets offer an eco-friendly alternative. Metal is a 100% recyclable material, and using perforated sheets can lead to reduced material waste during manufacturing processes. Furthermore, their lightweight nature contributes to lower energy consumption during transportation and installation, aligning with contemporary green building practices.

Conclusion

In conclusion, metal sheets with holes are an essential material in various sectors, from architecture to industrial manufacturing. Their versatility, lightweight nature, and ability to provide functional benefits such as filtration, ventilation, and aesthetic appeal make them a popular choice among designers and engineers. As sustainability continues to be a priority, perforated metal sheets are set to play an even more significant role in future innovations and applications. Whether in enhancing building designs or improving industrial efficiency, the use of these sheets exemplifies the confluence of functionality and creativity in material design.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.