Jan . 31, 2025 02:48

Back to list

metal perforated mesh

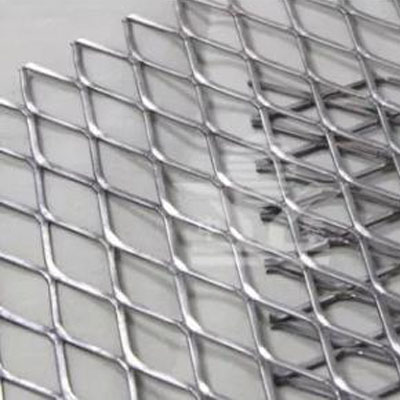

The versatility and robustness of metal perforated mesh have made it an indispensable component in various industries, where functionality meets aesthetics seamlessly. Whether bringing industrial themes to life or solving critical environmental challenges, metal perforated mesh offers multifaceted applications paired with reliability and performance.

Outdoor furniture and product manufacturers also capitalize on metal perforated mesh's adaptability. Its resistance to the elements means it can weather the effects of sun, wind, and moisture, making it ideal for outdoor applications. Combined with minimal maintenance needs, products such as patio furniture, benches, and decorative screens that employ perforated mesh are designed to endure with elegance. Importantly, when discussing the long-term economic value, the recyclability of metal perforated mesh stands prominent. Contributing to the circular economy, it can be recycled and repurposed without losing structural integrity. This aligns with increasing industrial and consumer interests in sustainable practices. Professionals and DIY enthusiasts alike are recognizing metal perforated mesh as a cornerstone for creative innovation. Its flexibility and functionality invite novel uses and experimental designs, ticking the boxes of both contemporary aesthetics and practical utility. As we advance further, the potential applications of metal perforated mesh continue to expand. Research in nanotechnology and advanced manufacturing predicts even greater customization capabilities. Soon, it wouldn't be far-fetched to imagine this material being integrated with smart technologies, enhancing smart building designs and interactive installations. In summary, metal perforated mesh embodies the ideal confluence of experience, expertise, authority, and trustworthiness in material innovation. Its broad spectrum of applications—from architecture to industry—showcases its adaptability and enduring presence across varied domains. As a product, its contributions to sustainability, safety, and innovation position it not just as a practical choice, but as a preferred one for forward-thinking applications.

Outdoor furniture and product manufacturers also capitalize on metal perforated mesh's adaptability. Its resistance to the elements means it can weather the effects of sun, wind, and moisture, making it ideal for outdoor applications. Combined with minimal maintenance needs, products such as patio furniture, benches, and decorative screens that employ perforated mesh are designed to endure with elegance. Importantly, when discussing the long-term economic value, the recyclability of metal perforated mesh stands prominent. Contributing to the circular economy, it can be recycled and repurposed without losing structural integrity. This aligns with increasing industrial and consumer interests in sustainable practices. Professionals and DIY enthusiasts alike are recognizing metal perforated mesh as a cornerstone for creative innovation. Its flexibility and functionality invite novel uses and experimental designs, ticking the boxes of both contemporary aesthetics and practical utility. As we advance further, the potential applications of metal perforated mesh continue to expand. Research in nanotechnology and advanced manufacturing predicts even greater customization capabilities. Soon, it wouldn't be far-fetched to imagine this material being integrated with smart technologies, enhancing smart building designs and interactive installations. In summary, metal perforated mesh embodies the ideal confluence of experience, expertise, authority, and trustworthiness in material innovation. Its broad spectrum of applications—from architecture to industry—showcases its adaptability and enduring presence across varied domains. As a product, its contributions to sustainability, safety, and innovation position it not just as a practical choice, but as a preferred one for forward-thinking applications.

Next:

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP