The Versatility and Applications of Metal Perforated Mesh

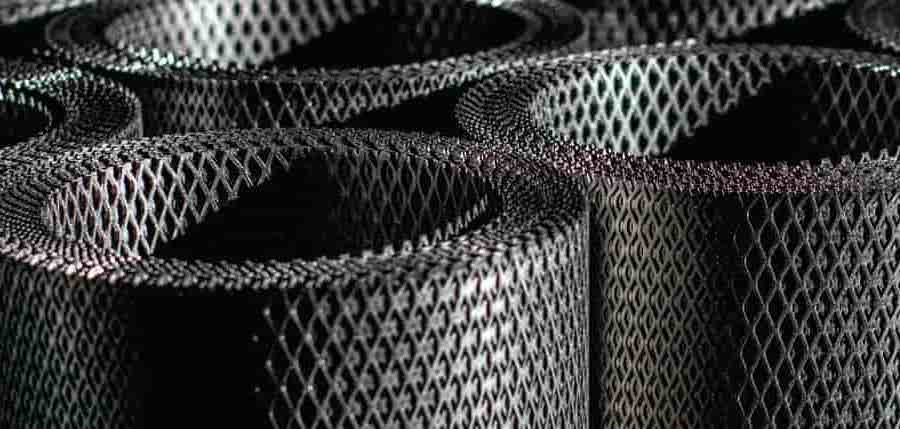

Metal perforated mesh, characterized by its unique structure and functional versatility, is an essential material in numerous industries. This specialized mesh is formed by the process of perforation, where patterns of holes are punched into sheets of metal, creating an array of openings that can vary in size, shape, and arrangement. The result is a lightweight yet durable mesh that offers a blend of aesthetic appeal and functional utility. This article explores the significance, manufacturing processes, and diverse applications of metal perforated mesh.

Manufacturing Processes

The production of metal perforated mesh typically involves several stages. First, a sheet of metal—commonly aluminum, stainless steel, or mild steel—is selected based on the desired properties such as strength, corrosion resistance, and weight. The next step is perforation, a process that can be achieved using various techniques, including mechanical punching, laser cutting, and water jet cutting. Each method offers distinct advantages in precision and design flexibility, allowing manufacturers to create intricate patterns and designs.

Finishing processes, such as anodizing, plating, or painting, often follow perforation to enhance the mesh's durability and aesthetic appeal. Anodizing provides a protective layer against corrosion, while paints and coatings can be applied in various colors to match specific design needs. The final product can either be sold as flat sheets or fabricated into specific shapes and sizes, depending on customer requirements.

Versatile Applications

1. Architectural Design One of the most notable applications of metal perforated mesh is in architectural design. It is frequently used as a facade element in buildings, providing both decorative appeal and functional benefits. The mesh can offer sun shading, ensuring that natural light enters while reducing heat gain. Additionally, the perforated design allows for airflow, contributing to better building ventilation.

metal perforated mesh

2. Industrial Uses In industrial settings, metal perforated mesh serves a wide range of purposes. It is commonly used for safety barriers, machinery guards, and sieves, ensuring that hazardous equipment is enclosed while allowing visibility and airflow. Furthermore, the mesh is employed in filtration systems to separate solid materials from liquids or gases, making it indispensable in manufacturing processes.

3. Automotive and Aerospace The automotive and aerospace sectors also leverage the benefits of metal perforated mesh. In vehicles, it is used in grilles and panels to allow for cooling airflow while maintaining a stylish appearance. In aerospace applications, the light weight and strength of the mesh make it suitable for various components within aircraft, contributing to overall fuel efficiency.

4. Furniture and Interior Design The aesthetic qualities of metal perforated mesh have made it increasingly popular in furniture design and interior decor. Designers utilize the material in creating statement pieces, such as room dividers, lighting fixtures, and decorative screens. The interplay of light and shadow through the mesh can create stunning visual effects in both residential and commercial spaces.

5. Environmental Applications Sustainability concerns have led to the use of metal perforated mesh in environmental applications. It is frequently employed in green building practices, helping to create eco-friendly designs that optimize energy efficiency. Moreover, it can be used in erosion control systems and as part of stormwater management solutions, contributing to enhanced environmental protection.

Conclusion

Metal perforated mesh is an invaluable material with extensive applications across various industries. Its unique combination of strength, versatility, and aesthetic appeal makes it a preferred choice for architects, designers, and engineers alike. As technology continues to advance, we can expect to see even more innovative uses of perforated mesh, solidifying its role as a staple in modern design and industrial practices. With its capacity to blend functionality with style, metal perforated mesh epitomizes the intersection of form and function, making it an enduring solution for contemporary challenges. Whether in the realm of architectural elegance or industrial efficiency, metal perforated mesh proves to be a material of endless possibilities.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.