Understanding Metal Bar Grating An Essential Component in Engineering and Construction

Metal bar grating has become an indispensable element in various industrial, commercial, and architectural applications. This versatile product, often made from steel, aluminum, or stainless steel, offers a combination of strength, durability, and functionality, making it ideal for numerous settings. This article aims to explore the characteristics, applications, benefits, and installation methods of metal bar grating, emphasizing its significance in modern engineering and construction.

What is Metal Bar Grating?

Metal bar grating consists of a series of horizontal or vertical bars that are spaced evenly apart to form a grid-like structure. These bars are typically produced from cold-rolled, hot-rolled, or welded materials, allowing for various configurations and designs to fit specific requirements. The spacing between the bars can be adjusted to provide different levels of support and drainage, making them suitable for a wide range of uses.

Key Characteristics

1. Strength and Durability Metal bar grating is built to withstand heavy loads, making it a reliable choice for applications in industrial settings where heavy machinery operates. The robust nature of materials like steel ensures extended service life, even in harsh environments.

2. Lightweight Design Despite its strength, metal bar grating is surprisingly lightweight. This feature makes it easier to handle and install, significantly reducing labor costs and time associated with transportation and setup.

3. Versatility One of the most appealing attributes of metal bar grating is its versatility. It can be used for flooring, walkways, platforms, and as safety barriers. Additionally, it comes in various finishes, such as galvanized or powder-coated, which enhances its resistance to corrosion.

4. Slip Resistance Many manufacturers offer a variety of surface treatments that provide slip resistance. This characteristic is particularly important in environments where water, oil, or other substances may create hazardous conditions.

Applications

Metal bar grating is utilized across diverse sectors, demonstrating its adaptability. Here are some common applications

- Industrial Facilities Used extensively in factories and refineries, metal bar grating serves as flooring, access platforms, and drainage covers. It supports heavy machinery and equipment, ensuring safety and efficiency.

metal bar grating

- Commercial Buildings In commercial settings, metal bar grating is employed for walkways, stairways, and fencing. Its aesthetic appeal, combined with practicality, enhances the interior and exterior design of buildings.

- Public Works Municipal projects such as bridges, sidewalks, and parks frequently incorporate metal bar grating to improve safety and accessibility while maintaining a clean sightline.

- Wastewater Treatment Plants Its ability to allow liquids to flow freely while providing a solid platform makes metal bar grating ideal for covering trenches and channels in wastewater facilities.

Benefits

Employing metal bar grating has numerous advantages, including

- Cost-Effectiveness While the initial investment may be higher compared to other materials, the long-term durability and reduced maintenance costs can lead to significant savings over time.

- Easy Installation and Maintenance Metal bar grating is designed for straightforward installation. Additionally, its low maintenance needs, particularly when treated for corrosion resistance, contribute to its overall efficiency.

- Environmental Impact Many metal gratings are made from recycled materials, and their longevity reduces the need for frequent replacements, making them an environmentally friendly option.

Installation Considerations

Proper installation is critical to maximizing the effectiveness of metal bar grating. This process includes assessing load requirements, selecting the appropriate spacing and type of grating, and ensuring secure anchoring to prevent movement or displacement. It’s essential to follow manufacturer guidelines and industry best practices to achieve optimal functionality and safety.

Conclusion

In summary, metal bar grating is more than just a structural component; it represents a fusion of engineering efficiency and aesthetic appeal. Its strength, durability, and versatility make it a preferred choice in various applications, from industrial sectors to commercial and municipal projects. As architects and engineers continue to seek innovative solutions, metal bar grating remains a vital resource that contributes to safer, more efficient, and environmentally sustainable construction practices. Whether you're managing a large production facility or designing a sleek commercial space, understanding and implementing metal bar grating can elevate the functionality and safety of your projects.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

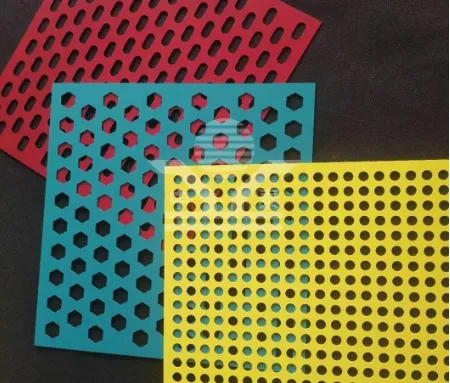

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.