Understanding Perforated Metal Sheets A Comprehensive Guide

In various industries, the demand for versatile and functional materials has led to the widespread use of perforated metal sheets. These sheets, characterized by their unique patterns of holes, have found applications in fields ranging from architecture to manufacturing. This article aims to delve into the intricacies of perforated metal sheets, including their production, benefits, uses, and considerations for purchasing.

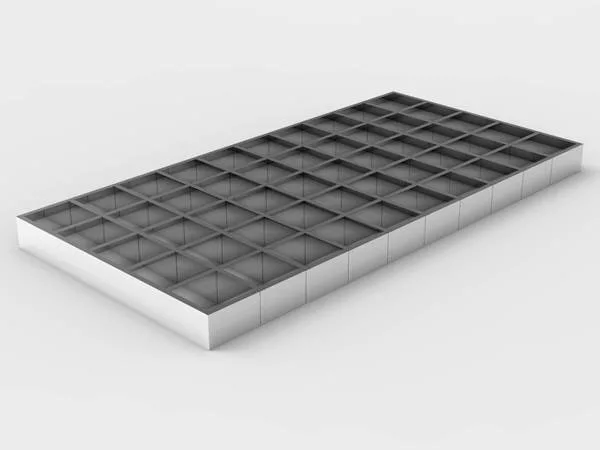

What is a Perforated Metal Sheet?

Perforated metal sheets are flat panels made of metal that feature a series of holes, either uniformly distributed or arranged in custom patterns. The manufacturing process involves punching holes into the sheet metal, allowing for a range of hole sizes, shapes, and distributions. The most common materials used for perforated sheets include stainless steel, aluminum, and carbon steel. The choice of material often depends on the specific use case, environmental conditions, and aesthetic preferences.

The Manufacturing Process

The production of perforated metal sheets typically begins with selecting a base material. Once the material is chosen, it undergoes a punching process using CNC (Computer Numerical Control) machinery. This technology ensures precision in the size and positioning of the holes. After the punching process, the sheets might be finished through processes like galvanization, powder coating, or painting to enhance their durability and resistance to corrosion.

Advantages of Perforated Metal Sheets

1. Versatility One of the primary benefits of perforated metal sheets is their versatility. They can be used in a wide range of applications—from architectural facades and ceiling tiles to filters and grilles.

2. Aesthetic Appeal Perforated sheets can add a decorative element to structures. The various hole patterns and finishes allow for creative designs that enhance the visual appeal of buildings and products.

3. Lightweight Yet Strong Despite being punched through with holes, perforated sheets maintain a high degree of structural integrity. This makes them lightweight and easy to handle, yet capable of withstanding significant stress.

4. Acoustic Properties Many industries require soundproofing or noise reduction. Perforated metal sheets can absorb sound effectively, making them ideal for use in music venues, theaters, and industrial settings.

5. Airflow and Ventilation The holes in perforated sheets allow for effective airflow, making them suitable for applications such as HVAC systems, where ventilation is critical to maintaining a comfortable environment.

jual perforated metal sheet

6. Customization Perforated metal sheets can be easily customized to fit specific dimensions and can feature a variety of hole shapes such as round, square, slotted, or decorative patterns. This allows for tailored solutions to meet diverse needs.

Applications of Perforated Metal Sheets

The applications of perforated metal sheets are diverse. In the architectural sector, they are used for building facades, interior designs, and ceiling panels, contributing both functional and aesthetic benefits. In industrial settings, they serve as filters and screens, effectively separating materials and enabling processes such as liquid filtration or air filtration. Additionally, perforated metal sheets are used in automotive parts, protective coverings, and fencing materials.

Considerations for Purchasing

When considering the purchase of perforated metal sheets, several factors should be taken into account

- Material Type Choose the appropriate material based on the environment and the intended use of the sheet. For example, stainless steel is better for outdoor applications due to its corrosion resistance.

- Hole Pattern and Size Determine the desired hole size and pattern based on aesthetic preferences and functional requirements.

- Thickness The thickness of the sheet should align with the application; thicker sheets generally provide better durability and load-bearing capabilities.

- Finish Depending on the environment, a specific finish may be required to enhance resistance to corrosion or wear.

Conclusion

Perforated metal sheets are an invaluable resource across various industries, combining functionality with aesthetic appeal. Their manufacturing process, versatility, and multitude of applications make them a popular choice for many design and construction projects. Whether for architectural innovation or industrial efficiency, understanding these sheets' characteristics can help make informed purchasing decisions that will lead to optimal results.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.