The Versatility of Iron Sheets with Holes Applications and Benefits

Iron sheets with holes, commonly known as perforated iron sheets, are increasingly being utilized in various industries due to their unique properties and benefits. These sheets are made from durable iron material and are characterized by a series of uniformly spaced holes that can vary in size, shape, and pattern. Their versatility is what makes them valuable across different applications, ranging from architecture to engineering.

Structural Integrity and Strength

One of the primary attributes of iron sheets is their inherent strength and durability. Iron, known for its high tensile strength, forms an effective substrate that can withstand heavy loads and stress. When these sheets are perforated, they retain a significant amount of structural integrity, owing to the ridges and support provided by the unperforated areas. This feature is essential in applications where safety and stability are paramount, such as in construction scaffolds and safety barriers.

Aesthetic Appeal

In addition to functionality, perforated iron sheets can enhance the aesthetic appeal of a design. The patterns formed by the holes can add an artistic touch to building facades and interior spaces. Architects and designers utilize these sheets to achieve a modern look while allowing for light and air to penetrate the structure. Various hole configurations can create unique shadows and visual effects that change throughout the day, making perforated sheets not just functional but also a critical component in architectural design.

Acoustic Properties

Another significant advantage of using perforated iron sheets is their sound-absorbing qualities. In environments where noise control is crucial, such as in auditoriums, concert halls, and offices, these sheets help mitigate sound reflection and enhance acoustic performance. The holes in the sheets disrupt sound waves, reducing reverberation and helping to maintain an enjoyable auditory environment. This makes them an invaluable asset in the fields of music, broadcasting, and general interior design.

iron sheet with holes

Air and Fluid Flow Management

Perforated iron sheets are ideal for applications involving air and fluid flow management. For example, they are commonly used in ventilation systems, allowing for adequate airflow while maintaining structural integrity. In water treatment facilities, perforated sheets can act as filters, aiding in the separation of sediment and other materials. These sheets can be adapted further for specific purposes, enabling customized solutions to meet the demands of different industries.

Industrial Applications

In the manufacturing sector, perforated iron sheets play a crucial role in machinery, component assembly, and packaging. They can be used as protective covers, packaging containers, or sorting trays, optimizing the production process. Their ability to provide visibility yet security makes them suitable for various industrial applications. Furthermore, the ability to customize hole size and arrangement allows for tailored solutions that meet specific operational needs.

Easy Maintenance and Longevity

Iron sheets, particularly when treated or coated, have excellent resistance to corrosion and wear. This quality ensures that perforated sheets can withstand exposure to harsh environments, making them an excellent choice for outdoor applications, such as fences and outdoor screens. Maintenance is typically minimal; regular inspections and cleaning can prolong their life and keep them looking good.

Conclusion

The applications of iron sheets with holes are vast and varied, covering aesthetic, structural, and functional roles in multiple industries. Their strengths lie not only in their durability and flexibility but also in their ability to enhance environmental performance through sound absorption and airflow management. As industries continue to evolve and the demand for customized solutions grows, perforated iron sheets will undoubtedly remain a staple in innovation and design. Their versatility opens the door to countless possibilities, making them an essential component in modern engineering and architecture. Whether used in artistic applications or practical engineering solutions, perforated iron sheets demonstrate the perfect blend of form and function.

-

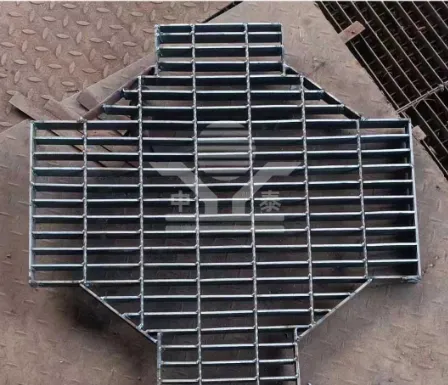

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.