The Versatile Applications of Perforated Iron Sheets

Perforated iron sheets, characterized by their unique pattern of holes, have emerged as one of the most versatile materials used across various industries. These sheets combine strength and durability with aesthetic appeal, making them an ideal choice for numerous applications, from architectural design to industrial uses.

Understanding Perforated Iron Sheets

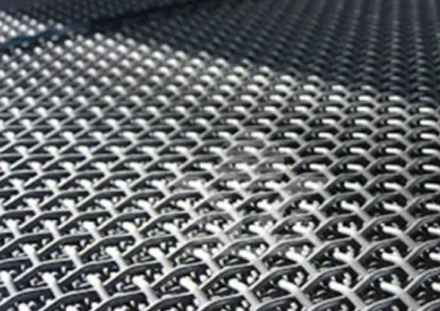

Perforated iron sheets are created by punching holes through iron panels, producing a variety of patterns and hole sizes to meet specific needs. The manufacturing process allows for great customization, permitting designers to select the shape, size, and arrangement of the holes. This flexibility is vital for applications that require unique designs or specific functionality.

One of the primary characteristics of perforated iron is its strength. Iron, being a robust metal, ensures that these sheets can withstand considerable weight and stress. Additionally, the perforation adds a degree of lightweight functionality, making transport and installation more manageable without sacrificing structural integrity.

Architectural Applications

In architecture, perforated iron sheets are increasingly popular due to their aesthetic and functional properties. They can be utilized as facade cladding, allowing natural light to filter through while providing privacy and protection from the elements. This feature is particularly valuable in urban environments where high-density buildings can create dark and oppressive spaces. Moreover, the varying hole patterns can be designed to enhance the visual appeal of a building, contributing to modern and innovative architectural styles.

Furthermore, perforated sheets are used in interior design for creating decorative screens or room dividers. The intricate patterns can evoke a sense of elegance and charm, making them suitable for both residential and commercial spaces. Additionally, their ability to provide ventilation while maintaining design integrity makes them a practical choice for areas that require airflow, such as lobbies or open office spaces.

perforated iron sheet

Industrial and Functional Uses

Beyond architecture, perforated iron sheets find extensive use in various industrial applications. They are commonly used in filtration systems, where they serve as a barrier to larger particles while allowing smaller substances to pass through. This is particularly crucial in sectors such as water treatment, dust collection, and air filtration, where maintaining quality is paramount.

Moreover, these sheets serve as protective barriers in numerous environments. For example, they can be employed in making protective enclosures or guards for machinery, ensuring safety without obstructing visibility. The perforations allow for air circulation, preventing overheating while safeguarding workers and equipment.

Environmental Considerations

The use of perforated iron sheets also aligns with modern sustainability efforts. By allowing natural light to illuminate spaces, these sheets can reduce the need for artificial lighting, leading to lower energy consumption. Additionally, perforated structures can promote green building practices, where natural cooling and ventilation are maximized, resulting in more environmentally friendly buildings.

Conclusion

In conclusion, perforated iron sheets are a remarkable material that balances functionality with aesthetics. Their diverse applications in architecture, interior design, and industrial sectors showcase their versatility and adaptability. As industries continue to seek innovative solutions that respect both functionality and design, perforated iron sheets are likely to play an increasingly prominent role in the materials used for construction and manufacturing. The ongoing exploration of their potential will undoubtedly lead to new uses and designs that enhance our environments, making them more beautiful and functional.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.