Understanding Industrial Sound Barriers An Essential Solution for Noise Pollution

In today's rapidly industrializing world, noise pollution has become a prevalent issue, particularly in urban areas where factories, construction sites, and transportation hubs operate continuously. The rise in industrial activities has led to an increase in ambient noise levels, which can have detrimental effects on public health, worker productivity, and overall quality of life. One effective solution to combat this problem is the implementation of industrial sound barriers. These structures are designed to reduce noise pollution and create a more conducive living and working environment.

What Are Industrial Sound Barriers?

Industrial sound barriers are specially engineered walls or enclosures that are strategically placed around noise-producing sources in industrial settings. These barriers are typically made from materials such as concrete, metal, or composite materials, which are specifically chosen for their sound-absorbing and sound-reflecting properties. Their primary purpose is to block the transmission of sound waves from the noise source to the surrounding areas, thus minimizing the impact of noise on local communities and workers.

How Do Sound Barriers Work?

The mechanism of sound barriers is based on the principles of sound transmission and attenuation. When sound waves encounter a barrier, they can either be reflected back, absorbed, or transmitted through the material. The effectiveness of a sound barrier depends primarily on its height, density, and the frequency of the sound being generated.

1. Height Taller barriers are generally more effective in blocking sound, as they disrupt the line of sight between the noise source and the receiver. For instance, a barrier that extends several feet above the source can significantly reduce noise levels experienced in nearby residential areas.

2. Density Heavier materials are more effective at absorbing sound energy. This is why concrete is often used for industrial sound barriers, as its mass prevents sound waves from passing through easily. The density helps diminish the sound's intensity, thereby providing a quieter environment.

3. Frequency Different materials absorb various sound frequencies differently. Low-frequency sounds (such as those generated by heavy machinery) can be particularly challenging to mitigate. Therefore, the choice of materials for sound barriers must consider the specific sound profile of the industrial operations.

industrial sound barriers

Benefits of Industrial Sound Barriers

The implementation of industrial sound barriers offers a myriad of benefits that extend beyond just reducing noise levels

1. Improved Health and Well-being Excessive noise exposure can lead to a range of health problems, including stress, sleep disturbances, and cardiovascular issues. By mitigating noise pollution, sound barriers contribute to improved overall health for workers and nearby residents.

2. Enhanced Worker Productivity In industrial facilities, high noise levels can lead to decreased focus and efficiency among workers. Reducing ambient noise helps to create a more productive workplace, where employees can concentrate on their tasks without unnecessary auditory distractions.

3. Community Relations By investing in sound barriers, companies demonstrate their commitment to being good neighbors. This can foster a positive relationship with the surrounding community, leading to increased support for industrial activities and potentially leading to less regulatory scrutiny.

4. Regulatory Compliance Many regions have strict regulations regarding noise levels in industrial zones. Installing sound barriers can be an effective way for companies to comply with these regulations, thus avoiding potential fines or legal issues.

Conclusion

Industrial sound barriers are a practical and effective solution to the pressing problem of noise pollution associated with industrial activities. By reducing sound transmission and improving the quality of life for nearby residents and workers, these structures play a critical role in fostering a more harmonious balance between industrial development and community well-being. As industries continue to grow and expand, the importance of implementing sound mitigation strategies, such as sound barriers, will only increase. Investing in these solutions not only benefits the immediate environment but also contributes to a sustainable future where industrial growth can coexist with public health considerations.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

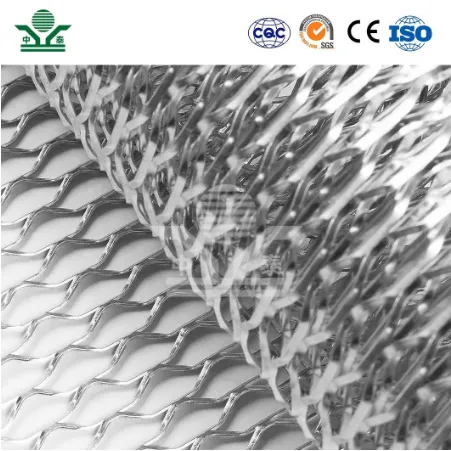

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.