Exploring Honeycomb Perforated Sheet Metal Versatile Solutions for Modern Design

In the world of materials and design, honeycomb perforated sheet metal stands out as a remarkable innovation that combines functionality with aesthetic appeal. This unique material, characterized by its intricate honeycomb structure and perforated pattern, has found applications across various industries, including architecture, automotive, and aerospace. In this article, we will delve into the characteristics, benefits, and uses of honeycomb perforated sheet metal.

Characteristics of Honeycomb Perforated Sheet Metal

Honeycomb perforated sheet metal is fabricated from thin sheets of metal that are perforated to create a structured pattern resembling a honeycomb. This design not only enhances the visual appeal of the metal but also contributes to its lightweight and strength. The perforation can vary in size and shape, allowing designers to customize the sheet metal for specific applications. Common materials used for honeycomb perforated sheet metal include aluminum, stainless steel, and galvanized steel, each offering different properties, such as corrosion resistance, weight, and durability.

Benefits of Honeycomb Perforated Sheet Metal

1. Lightweight Yet Durable One of the most significant advantages of honeycomb perforated sheet metal is its lightweight nature. Despite its reduced weight, the honeycomb structure provides excellent structural integrity, making it ideal for applications where weight savings are critical, such as in the aerospace and automotive industries.

2. Aesthetic Appeal The perforated design not only serves functional purposes but also adds a modern touch to architectural projects. The ability to customize hole patterns allows architects and designers to create visually striking facades, ceilings, and decorative features.

3. Enhanced Acoustic Properties Honeycomb perforated sheet metal can effectively reduce noise levels, making it suitable for use in environments where sound control is essential, such as concert halls, theaters, and public spaces. The perforations allow sound waves to be absorbed, resulting in improved acoustics.

4. Ventilation and Airflow The perforated holes in the sheet metal enable efficient airflow, making it a popular choice for ventilation systems, machinery covers, and enclosures. The honeycomb design promotes optimal air circulation, which is crucial for cooling and ventilation purposes.

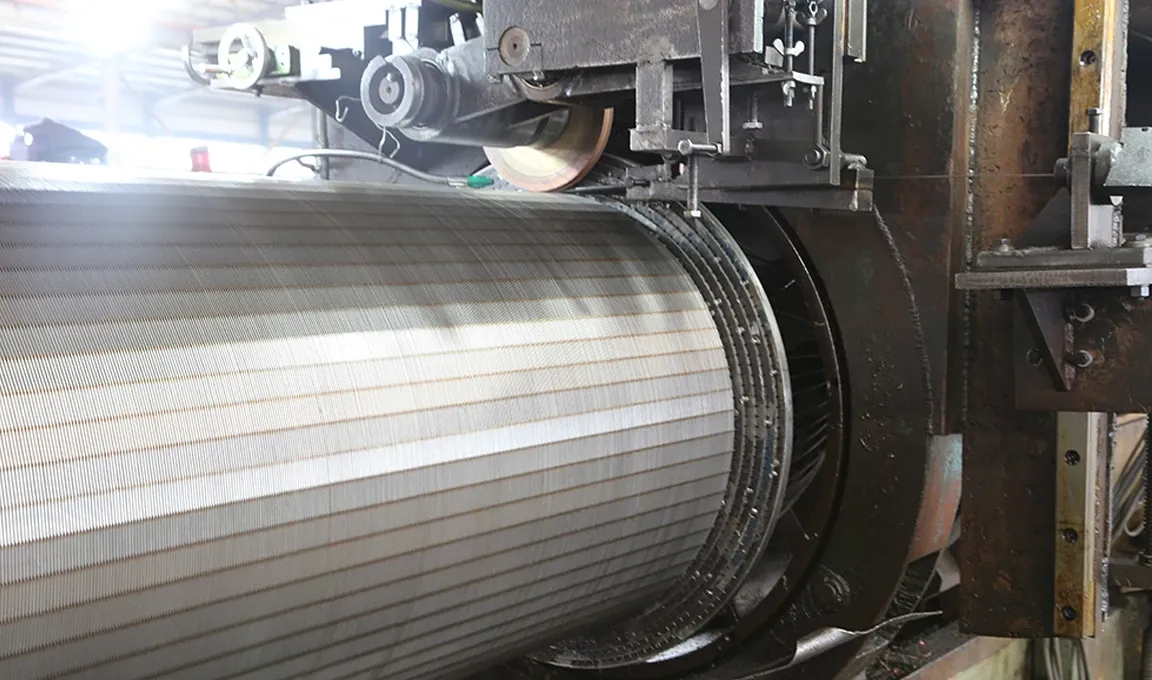

honeycomb perforated sheet metal

5. Versatile Applications Honeycomb perforated sheet metal is incredibly versatile and can be used in a range of applications. From decorative panels in interior design to functional components in industrial machinery, its adaptability makes it a preferred choice for designers and engineers.

Uses of Honeycomb Perforated Sheet Metal

The applications of honeycomb perforated sheet metal are diverse and include

- Architectural Facades Its aesthetic qualities make it an ideal choice for modern buildings, providing a unique exterior while allowing natural light to filter through.

- Automotive Interior In car manufacturing, honeycomb perforated sheet metal is used in trim and paneling, adding style without compromising on weight.

- Industrial Equipment This material is employed in machinery for protective covers, grilles, and guarding to prevent debris while maintaining airflow.

- Furniture Design Designers utilize honeycomb perforated sheets in creating contemporary furniture pieces, enhancing both functionality and style.

Conclusion

Honeycomb perforated sheet metal represents a remarkable intersection of design and engineering, offering lightweight durability, aesthetic flexibility, and practical functionality. As industries continue to evolve and demand innovative materials, the versatility of honeycomb perforated sheet metal ensures its relevance in modern applications. Whether in architecture, automotive design, or industrial use, this exceptional material is set to shape the future of design and construction, proving that function and form can indeed go hand in hand.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.