The Versatility of Holed Metal Sheets in Modern Applications

Holed metal sheets have become an indispensable material in various industrial and commercial applications. Their unique structure, characterized by a pattern of holes or perforations, offers a multitude of benefits that enhance functionality, aesthetics, and performance across several fields.

Understanding Holed Metal Sheets

Holed metal sheets are typically made from materials such as aluminum, stainless steel, or galvanized steel. The perforations in these sheets can vary in size, shape, and spacing, allowing for customization according to specific requirements. The process of creating these sheets involves different techniques such as laser cutting, punching, or drilling, each offering precise control over the hole specifications.

Applications Across Industries

1. Architecture and Design In the realm of architecture, holed metal sheets are frequently used as façade cladding. They provide an appealing aesthetic while allowing light to pass through, creating dynamic visual effects. The perforations can also contribute to energy efficiency by minimizing heat absorption and promoting ventilation. Designers often use these sheets for sunshades, balconies, and decorative wall panels, merging functionality with artistic expression.

2. Automotive Manufacturing The automotive industry employs holed metal sheets for various components such as grills, speaker covers, and interior design elements. The lightweight nature of these sheets combined with their strength makes them ideal for manufacturing parts that need to withstand stress without adding excessive weight to the vehicle.

3. Construction In construction, holed metal sheets are used in numerous applications including ventilation systems, fencing, and stairways. Their ability to allow airflow while providing structural integrity makes them valuable in creating spaces that are both functional and safe. For instance, perforated metal can be used to create safety barriers that offer visibility without sacrificing security.

holed metal sheet

4. Acoustic Applications Another significant use of holed metal sheets is in acoustic engineering. The perforations help in sound absorption and transmission, making them perfect for use in concert halls, auditoriums, and recording studios. By strategically designing the size and pattern of the holes, engineers can control sound dispersion and ensure optimal acoustics.

5. Filtration Systems In industries such as food processing and chemical manufacturing, holed metal sheets serve as effective filtration solutions. Their precise hole sizes allow for the separation of liquids and solids, enhancing the efficiency of the production processes. Moreover, these sheets can be easily cleaned and reused, providing a cost-effective and sustainable filtration method.

Advantages of Holed Metal Sheets

The popularity of holed metal sheets stems from several key advantages. First, their lightweight nature reduces shipping costs and eases installation. Secondly, the versatility of design means they can be tailored to meet specific needs, whether for practical usage or decorative purposes. Additionally, the durability of materials used ensures a long lifespan, even in harsh environments, making them a favorable choice for both indoor and outdoor applications.

Environmental Considerations

As industries increasingly focus on sustainability, the use of holed metal sheets can be aligned with eco-friendly practices. They can be fabricated from recycled materials, and their long-lasting properties reduce the need for frequent replacements. Furthermore, when used in construction, they can improve energy efficiency, thereby lowering the overall carbon footprint of a building.

Conclusion

Holed metal sheets represent a convergence of practicality and creativity, making them a vital component in numerous fields. From enhancing architectural designs to improving industrial processes, their applications are diverse and ever-expanding. With ongoing advancements in manufacturing technologies, the future of holed metal sheets looks promising, catering to an increasing demand for innovative and sustainable solutions across various industries.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

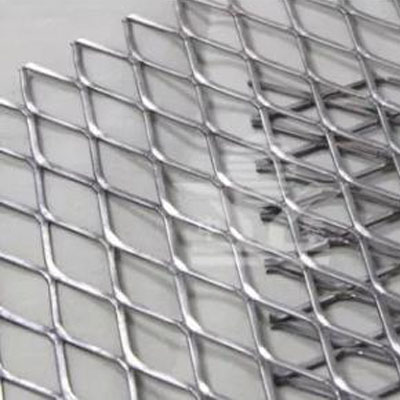

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.