Understanding 1% 204% Perforated Aluminum Sheet

Perforated aluminum sheets are versatile materials that find applications across various industries due to their unique combination of properties. When referring to a 1% 204% perforated aluminum sheet, it may initially seem perplexing. However, breaking down this term reveals a lot about what makes this material special and its potential uses.

Overview of Perforated Aluminum Sheets

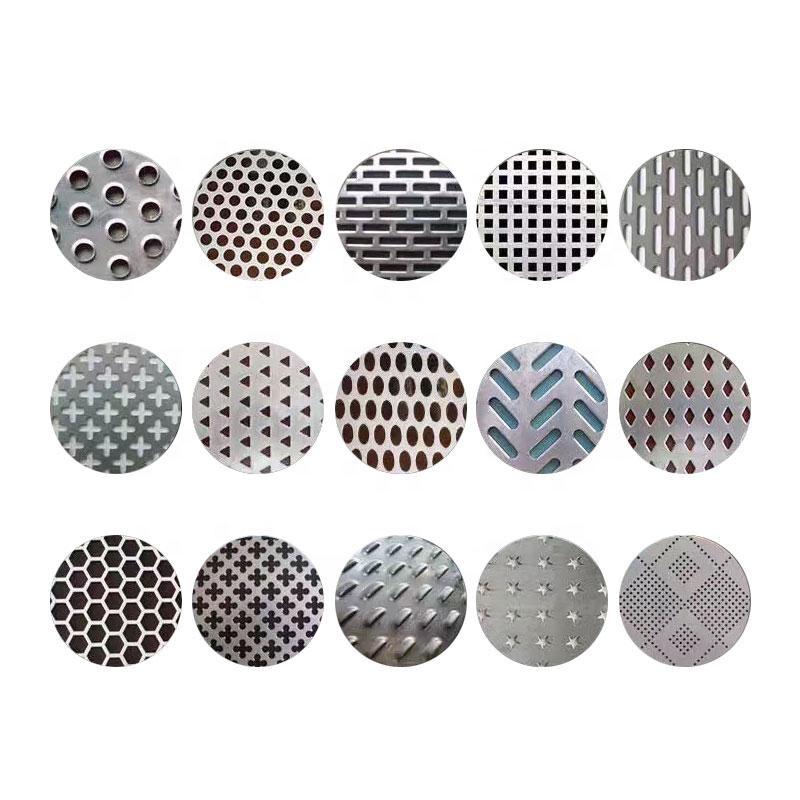

Perforated aluminum sheets are essentially aluminum sheets that have been mechanically stamped or punched to create a pattern of holes. These holes can vary in size, shape, and arrangement, tailored to meet specific requirements for aesthetic appeal, functionality, or both. Aluminum itself is known for its lightweight, corrosion resistance, and strength, making it an ideal choice for various applications.

The Significance of 1% and 204%

The numbers 1% and 204% may refer to specific characteristics or performance metrics, which can include the percentage of open area provided by the holes or perhaps the percentage increase in material efficiency compared to solid sheets. In the case of perforated materials, the open area percentage is crucial, as it dictates air flow, light penetration, and drainage capabilities in applications such as screens and partitions.

When considering a sheet with a 1% open area, it means that only a small part of the sheet is open to the environment, which can be advantageous for applications requiring a level of privacy or noise reduction. On the contrary, a 204% reference could suggest a highly efficient design or a specific type of usage where the balance of structural integrity and openness is optimized.

Applications in Various Industries

1 4 perforated aluminum sheet

1. Architecture and Construction Perforated aluminum sheets are widely used in building facades, sunshades, and railings. Their aesthetic appeal combined with functionality, such as allowing light while reducing heat, makes them a popular choice for modern architecture. The ability to customize hole patterns also means they can be integrated seamlessly into design elements.

2. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, these sheets are often used in diffusers and screens, where air flow is essential. A 1% perforation might be suitable for instances where restricted airflow is necessary while still providing ventilation.

3. Automotive Industry Lightweight yet durable materials are essential in the automotive industry to improve fuel efficiency without compromising safety. Perforated aluminum sheets are used for various components, including grilles and interior panels, which benefit from reduced weight while maintaining structural integrity.

4. Consumer Products From lighting fixtures to furniture, the creative use of perforated aluminum can add a modern touch to consumer products. The ability to create unique designs while ensuring the product remains lightweight and strong makes this material a preferred choice among designers.

Advantages of Using Perforated Aluminum Sheets

- Lightweight yet Strong The high strength-to-weight ratio of aluminum allows for ease of transportation and installation. - Corrosion Resistance Aluminum naturally forms a protective oxide layer, making it suitable for both indoor and outdoor applications. - Versatile Aesthetics With customizable hole patterns and finishes, perforated aluminum sheets can complement any design.

Conclusion

In a nutshell, 1% 204% perforated aluminum sheets illustrate the remarkable versatility and functionality of this material in modern applications. By understanding the specific characteristics denoted by the percentages, industries can leverage the unique benefits of perforated aluminum to create products that are not only practical but also aesthetically appealing. As innovation continues to evolve, the use of perforated aluminum will undoubtedly play a significant part in developing solutions that meet contemporary demands across various sectors.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.