Jan . 26, 2025 08:57

Back to list

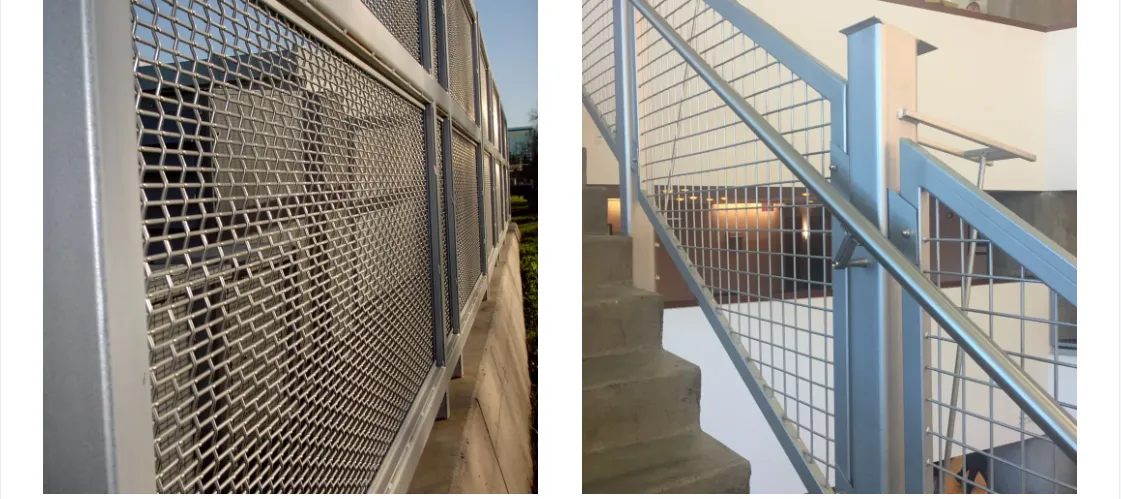

Traffic Trench Drain Grate China Manufacturing Metal Security Window Grates

Heavy duty stainless steel grating has become an indispensable component in industries where high strength, resilience, and safety are paramount. These gratings are known for their robustness and versatility, finding applications in sectors ranging from construction to manufacturing and even in residential setups. What sets this product apart is its ability to maintain integrity under extreme conditions while facilitating efficient drainage and ventilation.

Trustworthiness is perhaps the most compelling trait of heavy duty stainless steel grating. When industries manage valuable assets—be it in aerospace, maritime, or urban infrastructure—the reliability of structural components becomes crucial. These gratings support vast weights and structural elements, providing an assurance that comes from rigorous testing and quality checks. Manufacturers provide certifications and warranties that underscore their commitment to quality, ensuring customers that they are investing in a product that won't fail under pressure. Moreover, the stainless steel industry maintains transparency in its practices, enhancing consumer trust. The recyclability of stainless steel aligns with sustainable development goals, showcasing an environmentally responsible choice without compromising on performance. The widespread adoption of heavy duty stainless steel grating can also be attributed to its adaptability. Whether the requirement is for a moisture-heavy environment or a load-bearing structure, these gratings can be customized to suit different needs. With various configurations available, such as welded, press-locked, or swage-locked, customers can select a design that perfectly aligns with their operational requirements without sacrificing any of the core benefits. In conclusion, heavy duty stainless steel grating exemplifies a synergy of experience, expertise, authority, and trust. It serves as a backbone for many infrastructures, offering unyielding support and safety. Industries looking to enhance their operational efficiency, safety, and long-term sustainability find in stainless steel grating an unparalleled product that meets stringent demands and delivers consistently remarkable results.

Trustworthiness is perhaps the most compelling trait of heavy duty stainless steel grating. When industries manage valuable assets—be it in aerospace, maritime, or urban infrastructure—the reliability of structural components becomes crucial. These gratings support vast weights and structural elements, providing an assurance that comes from rigorous testing and quality checks. Manufacturers provide certifications and warranties that underscore their commitment to quality, ensuring customers that they are investing in a product that won't fail under pressure. Moreover, the stainless steel industry maintains transparency in its practices, enhancing consumer trust. The recyclability of stainless steel aligns with sustainable development goals, showcasing an environmentally responsible choice without compromising on performance. The widespread adoption of heavy duty stainless steel grating can also be attributed to its adaptability. Whether the requirement is for a moisture-heavy environment or a load-bearing structure, these gratings can be customized to suit different needs. With various configurations available, such as welded, press-locked, or swage-locked, customers can select a design that perfectly aligns with their operational requirements without sacrificing any of the core benefits. In conclusion, heavy duty stainless steel grating exemplifies a synergy of experience, expertise, authority, and trust. It serves as a backbone for many infrastructures, offering unyielding support and safety. Industries looking to enhance their operational efficiency, safety, and long-term sustainability find in stainless steel grating an unparalleled product that meets stringent demands and delivers consistently remarkable results.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP