The Benefits of Heavy-Duty Bar Grating in Industrial Applications

Heavy-duty bar grating is an essential component in various industrial applications, serving as a reliable solution for flooring, walkways, and platforms. Constructed from high-quality materials such as steel or aluminum, heavy-duty bar grating is designed to withstand substantial loads and harsh environmental conditions. This article explores the benefits and applications of heavy-duty bar grating, highlighting why it is a preferred choice in numerous industries.

Strength and Durability

One of the most significant advantages of heavy-duty bar grating is its strength and durability. This type of grating is engineered to bear heavy loads without bending or deforming. It is often used in areas where heavy machinery operates and where pedestrian traffic is common. The robust construction ensures that the grating can withstand impacts and resist corrosion, making it suitable for outdoor environments or facilities where exposure to chemicals is a concern.

Versatility in Design

Heavy-duty bar grating comes in various designs and configurations, making it versatile for different applications. Manufacturers offer a range of materials, including carbon steel, stainless steel, and fiberglass, allowing users to select the best option based on specific needs. Additionally, bar spacing can be customized to meet specific requirements, ensuring safety while allowing for efficient water drainage and airflow.

Safety Features

Safety is paramount in industrial settings, and heavy-duty bar grating excels in providing a secure walking surface. The grid-like structure of the grating ensures excellent slip resistance, even in wet or oily conditions. This characteristic significantly reduces the risk of slips and falls, making it a preferred choice for walkways, catwalks, and staircases in factories, warehouses, and outdoor environments.

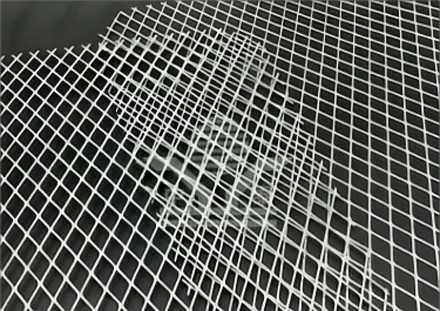

heavy duty bar grating

Cost-Effectiveness

While the initial investment in heavy-duty bar grating may be higher than traditional flooring options, its long-term cost-effectiveness cannot be overlooked. The durability and low maintenance requirements of heavy-duty grating reduce the need for frequent replacements and repairs. Consequently, organizations can save on costs associated with replacement materials and labor over time. Its longevity also means that companies can allocate their budgets to other critical areas rather than recurring flooring expenses.

Environmentally Friendly Options

With growing awareness of environmental sustainability, many manufacturers now produce eco-friendly heavy-duty bar grating options. For instance, aluminum grating is fully recyclable, making it an excellent choice for organizations committed to green practices. By opting for sustainable materials, companies can enhance their environmental footprint while still benefiting from the performance features of heavy-duty grating.

Applications in Various Industries

Heavy-duty bar grating is utilized across numerous sectors, including manufacturing, oil and gas, aerospace, and food processing. In manufacturing, it provides sturdy flooring for assembly lines. In the oil and gas industry, it is often used for offshore platforms and refineries due to its resistance to corrosion and extreme conditions. In the food processing sector, heavy-duty grating ensures sanitary conditions, as it allows for easy cleaning and prevents water pooling.

Conclusion

Heavy-duty bar grating is a vital material that offers a combination of strength, safety, and versatility, making it ideal for many industrial applications. Its durability and customizable designs cater to various operational requirements, while its slip-resistant surface enhances workplace safety. With its long-term cost-effectiveness and eco-friendly options, heavy-duty bar grating continues to be a preferred choice in industries aiming for both performance and sustainability. Whether for flooring, walkways, or specialized platforms, heavy-duty bar grating stands out as a trusted solution in the industrial landscape.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.