Understanding Heavy Duty Bar Grating An Essential Component in Industrial Applications

Heavy duty bar grating is a crucial material used across a variety of industrial applications. Designed to support significant loads while facilitating drainage, ventilation, and visibility, heavy duty bar grating is widely favored in industries ranging from manufacturing to construction. This article explores the key characteristics, advantages, applications, and the selection process of heavy duty bar grating.

What is Heavy Duty Bar Grating?

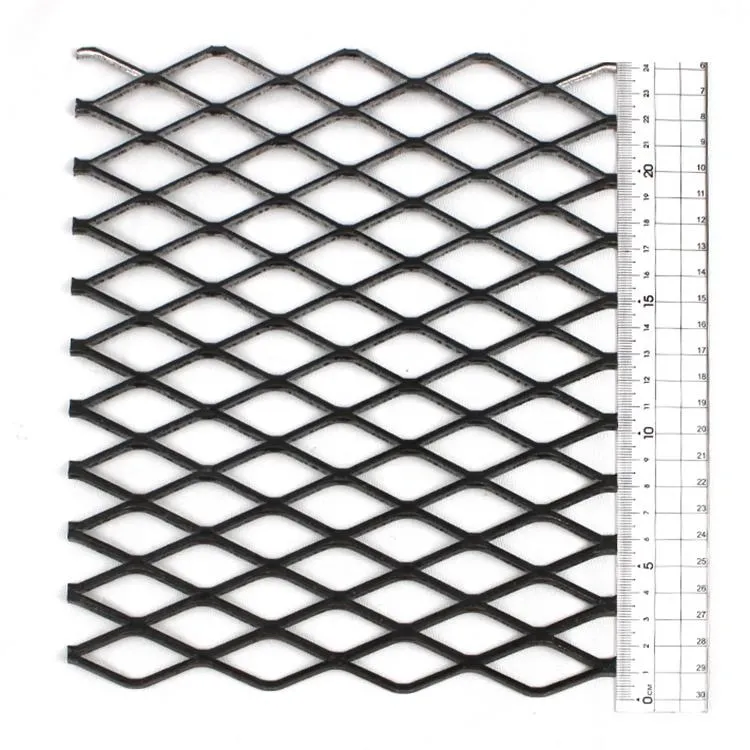

Heavy duty bar grating is composed of parallel bars that are typically made of steel, aluminum, or fiberglass. These bars are welded or mechanically assembled to create a grid-like structure, which allows for maximum strength and load-bearing capabilities. The spacing between the bars can vary, making it suitable for different operational needs and environments.

One of the defining features of heavy duty bar grating is its ability to endure high traffic loads while ensuring safety and stability. This capability makes it ideal for areas where heavy machinery operates or where substantial foot traffic occurs.

Advantages of Heavy Duty Bar Grating

1. Strength and Durability Heavy duty bar grating is designed to withstand extreme conditions, including high weights and dynamic forces. This durability ensures a long service life, reducing the need for frequent replacements.

2. Slip Resistance Many types of heavy duty bar grating come with slip-resistant surfaces. This feature significantly enhances safety in industrial environments, where spills and wet conditions are common.

3. Low Maintenance Due to its robust construction, heavy duty bar grating requires minimal maintenance. Its resistance to corrosion, when made from stainless steel or treated aluminum, adds to its long-lasting nature.

4. Versatility Available in various materials, sizes, and configurations, heavy duty bar grating can be adapted to specific needs, making it appropriate for walkways, platforms, and industrial flooring.

5. Ease of Installation Heavy duty bar grating can be easily cut and assembled on-site. This flexibility allows for quick installation, minimizing downtime in operations.

Applications of Heavy Duty Bar Grating

Heavy duty bar grating is utilized in multiple settings, including

- Manufacturing Facilities It serves as flooring on production lines, providing both drainage and support for heavy machinery.

heavy duty bar grating

- Power Plants Heavy duty bar grating is essential for walkways and platforms, allowing workers to move safely around heavy equipment.

- Wastewater Treatment Plants Its design facilitates efficient drainage while supporting the weight of machinery and personnel.

- Commercial Buildings In parking garages and loading docks, heavy duty bar grating ensures safety and durability under heavy vehicle traffic.

- Marine Applications Anti-slip and corrosion-resistant grating is used in shipbuilding and port terminals to ensure safety and efficiency.

Choosing the Right Heavy Duty Bar Grating

Selecting the appropriate heavy duty bar grating for a specific application involves considering various factors

1. Load Requirements It's essential to evaluate the maximum load that the grating will support to ensure it meets safety and performance standards.

2. Material Depending on the environmental conditions, different materials may be more suitable. For instance, aluminum is lightweight and corrosion-resistant, while steel provides strength and durability.

3. Bar Spacing The spacing between the bars should allow for adequate drainage without compromising strength. This is particularly important in applications involving liquid runoff.

4. Safety Features Slip resistance is vital in environments prone to spills. Choosing grating with appropriate surface treatment enhances worker safety.

5. Budget Constraints While opting for quality is important, budget considerations will also play a significant role in the selection process.

Conclusion

Heavy duty bar grating is a foundational component in various industrial applications, offering safety, durability, and functionality. Its adaptability to demanding environments and requirements makes it an essential choice for businesses looking to invest in reliable infrastructure. Understanding the specific needs of your operation and the characteristics of heavy duty bar grating will ensure optimal performance and longevity, ultimately contributing to the overall efficiency of industrial processes.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.