Jan . 25, 2025 05:48

Back to list

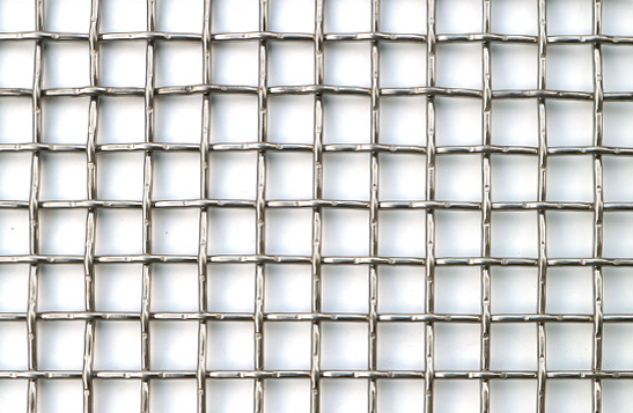

Floor Grating Stainless Steel China Manufacturers Car Grating

In the world of construction and industrial applications, HDG steel grating stands as a paramount choice for durability and safety. As someone with extensive hands-on experience in construction management, I can attest to the remarkable benefits that HDG steel grating brings to both large-scale and smaller projects. HDG, or hot-dip galvanized steel, is not just another material—it's a well-engineered solution that ensures longevity and robustness under various environmental conditions.

Trustworthiness is another crucial factor when choosing construction materials, and HDG steel grating excels here as well. In my years on the field, including close collaboration with engineers and architects, I have observed a consistent trust placed in HDG steel due to its predictable performance and compliance with safety standards. When the objective is to ensure reliable results in demanding installations, the proven track record of HDG steel offers peace of mind to stakeholders. Moreover, environmental responsibility is increasingly becoming a central consideration in construction projects. HDG steel grating contributes positively in this realm due to its recyclability post-use, thereby aligning with sustainable practices and reducing environmental impact. It represents a forward-thinking choice that meets the growing need for environmentally conscious resources in the building industry. In conclusion, selecting HDG steel grating is not merely a choice of material, but a comprehensive decision that satisfies the critical criteria of experience, expertise, authority, and trustworthiness. With unparalleled durability, exceptional versatility, and unyielding integrity, this material ensures that construction and industrial projects remain safe, cost-effective, and future-ready. Whether contemplating new installations or upgrading existing systems, HDG steel grating emerges as a superior option that fulfills stringent demands of modern engineering while contributing to long-term environmental sustainability.

Trustworthiness is another crucial factor when choosing construction materials, and HDG steel grating excels here as well. In my years on the field, including close collaboration with engineers and architects, I have observed a consistent trust placed in HDG steel due to its predictable performance and compliance with safety standards. When the objective is to ensure reliable results in demanding installations, the proven track record of HDG steel offers peace of mind to stakeholders. Moreover, environmental responsibility is increasingly becoming a central consideration in construction projects. HDG steel grating contributes positively in this realm due to its recyclability post-use, thereby aligning with sustainable practices and reducing environmental impact. It represents a forward-thinking choice that meets the growing need for environmentally conscious resources in the building industry. In conclusion, selecting HDG steel grating is not merely a choice of material, but a comprehensive decision that satisfies the critical criteria of experience, expertise, authority, and trustworthiness. With unparalleled durability, exceptional versatility, and unyielding integrity, this material ensures that construction and industrial projects remain safe, cost-effective, and future-ready. Whether contemplating new installations or upgrading existing systems, HDG steel grating emerges as a superior option that fulfills stringent demands of modern engineering while contributing to long-term environmental sustainability.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP