Understanding HDG Steel Grating Characteristics, Applications, and Benefits

HDG steel grating, or hot-dip galvanized steel grating, has become a preferred solution for a myriad of industrial and commercial applications due to its durability, strength, and resistance to corrosion. This article will delve into the characteristics, applications, and benefits of HDG steel grating, providing a comprehensive overview of this essential material.

What is HDG Steel Grating?

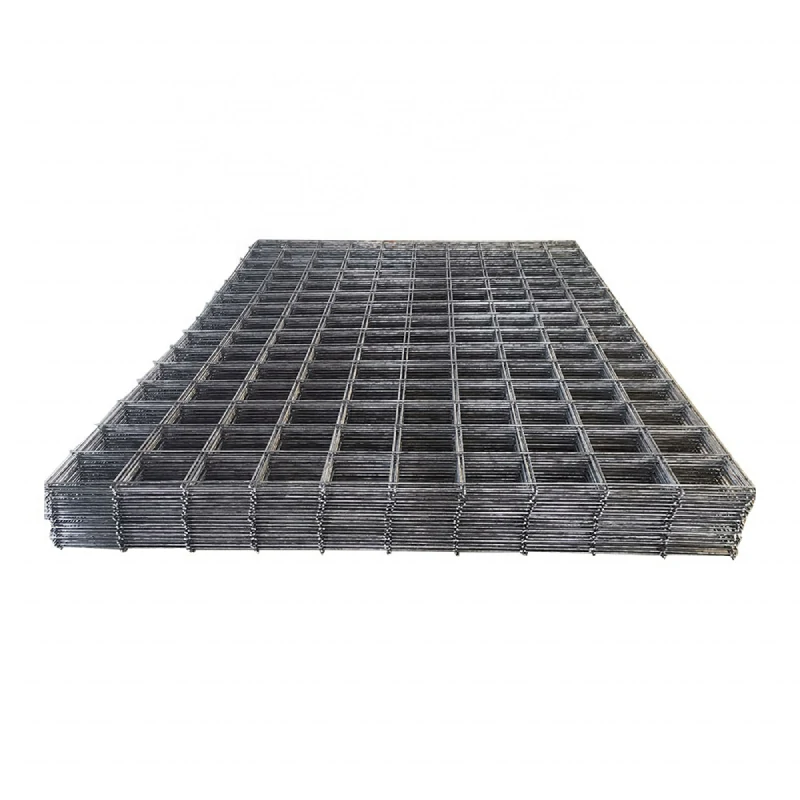

HDG steel grating is created from steel bars that are welded together to form a grid-like structure. The bars can be manufactured in various sizes and shapes, allowing for customization to meet specific project requirements. After the grating is fabricated, it undergoes a hot-dip galvanizing process, where the steel is immersed in molten zinc. This coating provides an extra layer of protection against environmental elements, making the grating suitable for outdoor and corrosive environments.

Key Characteristics

1. Strength and Durability HDG steel grating is known for its high load-bearing capacity, making it an ideal choice for applications that require heavy-duty support. The welded construction ensures robustness, while the galvanization process enhances its lifespan.

2. Corrosion Resistance The primary advantage of hot-dip galvanizing is its exceptional resistance to corrosion. The zinc coating acts as a barrier against moisture, chemicals, and other environmental factors that can lead to rusting and deterioration. This property is particularly valuable in harsh environments, such as coastal areas, chemical plants, or wastewater treatment facilities.

3. Safety Features Steel grating offers superior slip resistance, reducing the risk of accidents in high-traffic areas. The open design allows for debris, water, and light to pass through, which helps maintain visibility and improves safety conditions.

4. Reduced Maintenance Costs Because of its durability and corrosion resistance, HDG steel grating typically involves lower maintenance costs over its lifespan. It can withstand various environmental challenges, minimizing the need for frequent replacement or repair.

Applications of HDG Steel Grating

HDG steel grating finds application across a wide range of industries

hdg steel grating

1. Industrial Flooring Many manufacturing and processing facilities use HDG steel grating as flooring in walkways, platforms, and catwalks due to its strength and durability.

2. Drainage Systems The grating is commonly used in drainage systems to cover and protect open ditches, trenches, and drains, ensuring that debris does not clog the system while allowing water to flow freely.

3. Stair Treads and Ramps The slip-resistant properties of HDG steel grating make it an ideal choice for stair treads and ramps, providing safety for workers and visitors in industrial settings.

4. Fencing and Security Bars The rigid structure of steel grating can also be used in security applications, offering a combination of visibility and strength to deter unwanted access.

5. Architectural Features Beyond industrial use, HDG steel grating can be incorporated into architectural designs, such as facades and screens, adding both functionality and aesthetic appeal.

Benefits of Using HDG Steel Grating

1. Cost-Effectiveness Though the initial investment may appear higher than other materials, the longevity and reduced maintenance costs of HDG steel grating result in overall cost savings in the long term.

2. Environmental Sustainability The galvanizing process is environmentally friendly, and steel itself is recyclable. Utilizing HDG steel grating contributes to sustainable construction practices.

3. Customization Options HDG steel grating can be tailored to fit specific project dimensions and requirements, providing flexibility in design and application.

4. Rapid Installation The lightweight nature of steel grating facilitates easier handling and faster installation, minimizing downtime on job sites.

In conclusion, HDG steel grating is a versatile and reliable solution for various industrial and commercial applications. Its unique characteristics, combined with a broad range of applications and benefits, make it an invaluable asset in modern construction and manufacturing. With its high load capacity, resistance to corrosion, and safety features, HDG steel grating stands out as an essential material for creating durable and efficient environments. Whether for flooring, drainage, or security, the enduring value of HDG steel grating makes it a popular choice in today’s industries.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.