The Versatility and Advantages of HDG Steel Grating

Hot-dipped galvanized (HDG) steel grating is an essential component in various industrial and commercial applications, known for its strength, durability, and corrosion resistance. Produced through a process where steel is immersed in a molten zinc bath, HDG steel grating provides a protective layer that significantly enhances its lifespan. In this article, we will explore the characteristics, advantages, and applications of HDG steel grating.

Characteristics of HDG Steel Grating

HDG steel grating is designed to withstand heavy loads and harsh environments. The grating panels consist of a series of parallel steel bars, spaced evenly to create an open surface that allows for light, air, and drainage. This design not only ensures safety by preventing slips and falls but also promotes easy maintenance and cleaning. The hot-dipping process gives the steel a robust layer of zinc that acts as a barrier against moisture, chemicals, and other corrosive materials that might shorten the life of untreated steel.

Advantages of HDG Steel Grating

1. Corrosion Resistance One of the most significant benefits of HDG steel grating is its exceptional resistance to corrosion. The layer of zinc protects the underlying steel from rust and decay, making it suitable for outdoor and industrial environments, such as wastewater treatment plants, chemical processing facilities, and marine applications.

2. Strength and Durability HDG steel grating is engineered to support heavy loads, making it ideal for use in heavy machinery environments and pedestrian walkways. Its high tensile strength ensures that it can withstand extreme conditions without bending or breaking.

3. Low Maintenance The durability of HDG steel grating means that it requires minimal maintenance over time. Regular inspections and cleaning are often more than adequate to ensure its longevity, saving time and resources for businesses.

hdg steel grating

4. Safety The open design of steel grating allows debris to fall through, reducing fall hazards and promoting safety in workplaces. Additionally, the surface can be treated with anti-slip coatings to further enhance grip, making it safe for foot traffic and heavy equipment.

5. Cost-Effectiveness While the initial investment in HDG steel grating may be higher than other types of materials, its long lifespan and low maintenance costs make it a more cost-effective solution in the long run. Businesses can save money by avoiding frequent replacements and repairs.

Applications of HDG Steel Grating

HDG steel grating is highly versatile and can be found in a wide range of applications. In industrial settings, it is commonly used for walkways, platforms, and stair treads. Its resistance to chemicals makes it an excellent choice for factories, laboratories, and refineries. In commercial settings, HDG steel grating can be used in parking garages, outdoor stairways, and loading docks.

Additionally, HDG steel grating is often utilized in the construction of bridges, drainage covers, and security fencing. Its lightweight nature and ease of installation make it a popular option among architects and engineers, who appreciate both its functionality and aesthetic appeal.

Conclusion

In summary, HDG steel grating stands out due to its impressive properties and multifaceted applications. Its corrosion resistance, strength, low maintenance requirements, and safety features make it a valuable asset in many industries. As companies continue to seek durable materials that can withstand the rigors of their environments, HDG steel grating will undoubtedly remain a popular choice for years to come. Whether for industrial, commercial, or infrastructural purposes, the advantages of this material make it an indispensable component in modern construction and maintenance practices.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

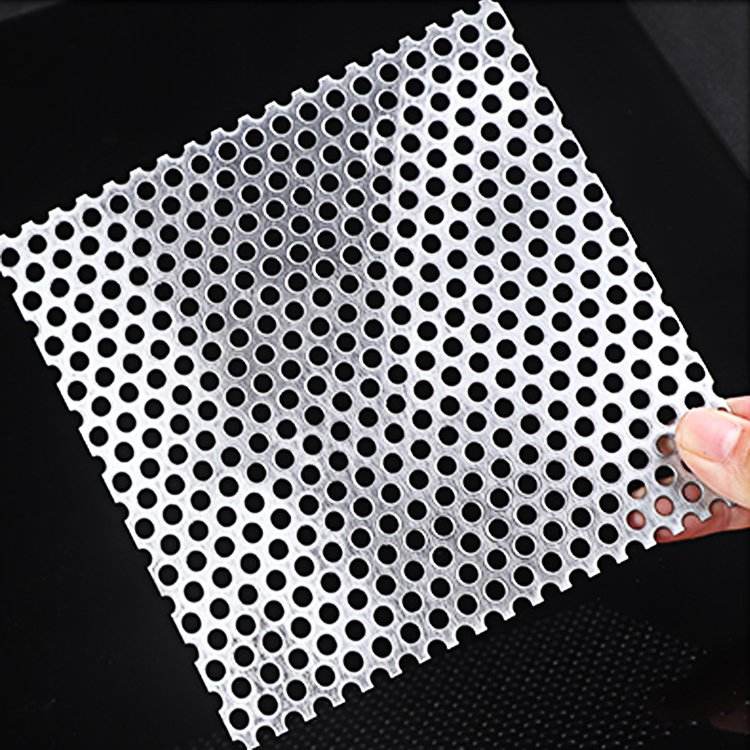

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.