Jan . 24, 2025 03:19

Back to list

drain channel & grating 1m steel grating

Grating treads are an essential element in various construction and industrial applications, providing a safe, durable, and efficient solution for areas requiring a secure footing. Whether utilized in commercial buildings, industrial facilities, or outdoor landscapes, grating treads significantly enhance safety and functionality in high-traffic areas. The selection of appropriate grating treads involves a combination of materials, designs, and finishes tailored to meet specific requirements. Understanding these components is crucial for anyone involved in the specification, purchase, or maintenance of grating treads.

Authoritativeness in the industry is demonstrated through rigorous testing and compliance with safety standards. Grating treads must adhere to specifications set by organizations such as the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA). These standards ensure that the products meet or exceed safety requirements, providing peace of mind to engineers and project managers. Additionally, many manufacturers offer third-party certification, providing an added layer of trustworthiness. The certification process includes load testing, corrosion resistance assessments, and slip resistance testing, ensuring the grating treads are equipped to handle their intended use. Real-world experience underscores the critical importance of professional installation and regular maintenance of grating treads. Incorrect installation can lead to issues such as instability, premature wear, or increased accident risk. It is paramount to engage trained professionals who use specialized equipment and techniques to ensure the treads are securely fastened and aligned. Post-installation, routine inspections and maintenance extend the lifespan of grating treads and ensure continued compliance with safety standards. Cleaning to remove debris and checking for signs of wear or corrosion are fundamental procedures that maintain the functionality and safety of grating treads. For businesses looking to enhance their facility's safety and efficiency, investing in high-quality grating treads engineered to meet specific needs is non-negotiable. The selection process should consider environment conditions, expected load, and compliance with safety regulations. Suppliers and manufacturers with a demonstrable track record provide invaluable guidance, ensuring that customers receive products that not only comply with industry standards but also deliver optimal performance. The commitment to quality, safety, and reliability not only reinforces the credibility of the grating treads but also establishes trust with all stakeholders involved in a construction or industrial project.

Authoritativeness in the industry is demonstrated through rigorous testing and compliance with safety standards. Grating treads must adhere to specifications set by organizations such as the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA). These standards ensure that the products meet or exceed safety requirements, providing peace of mind to engineers and project managers. Additionally, many manufacturers offer third-party certification, providing an added layer of trustworthiness. The certification process includes load testing, corrosion resistance assessments, and slip resistance testing, ensuring the grating treads are equipped to handle their intended use. Real-world experience underscores the critical importance of professional installation and regular maintenance of grating treads. Incorrect installation can lead to issues such as instability, premature wear, or increased accident risk. It is paramount to engage trained professionals who use specialized equipment and techniques to ensure the treads are securely fastened and aligned. Post-installation, routine inspections and maintenance extend the lifespan of grating treads and ensure continued compliance with safety standards. Cleaning to remove debris and checking for signs of wear or corrosion are fundamental procedures that maintain the functionality and safety of grating treads. For businesses looking to enhance their facility's safety and efficiency, investing in high-quality grating treads engineered to meet specific needs is non-negotiable. The selection process should consider environment conditions, expected load, and compliance with safety regulations. Suppliers and manufacturers with a demonstrable track record provide invaluable guidance, ensuring that customers receive products that not only comply with industry standards but also deliver optimal performance. The commitment to quality, safety, and reliability not only reinforces the credibility of the grating treads but also establishes trust with all stakeholders involved in a construction or industrial project.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

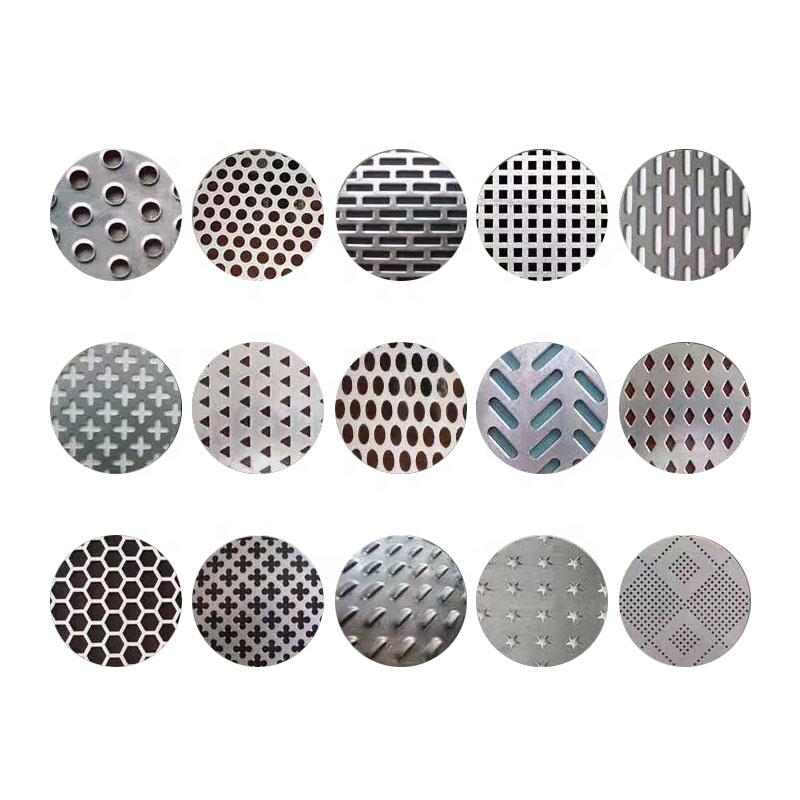

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP