Jan . 19, 2025 23:36

Back to list

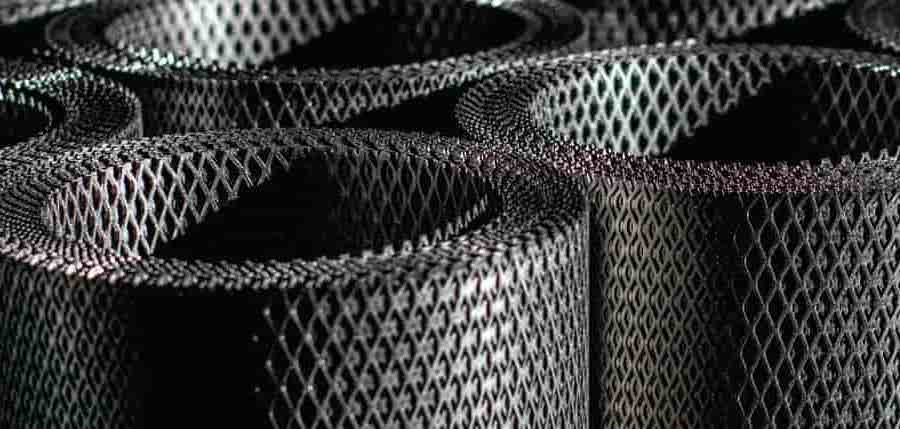

galvanized safety grating

Galvanized safety grating stands as a beacon of innovation in the world of industrial flooring solutions, demonstrating how functionality and durability can unite to provide maximum safety. As someone with extensive experience in the field of industrial safety solutions, I can attest to the indispensable role that galvanized safety grating plays across a range of industries worldwide.

In addition to practicality, galvanized safety grating lends itself to aesthetic applications. The sleek, metallic look integrates seamlessly into more contemporary designs, offering both functionality and visual appeal. This makes it highly relevant to architects and designers looking to incorporate industrial chic elements into their projects. The aesthetic component, while secondary to safety and durability, is nevertheless a value-add that should not be underestimated. Perhaps one of the most reassuring aspects of using galvanized safety grating is the industry’s commitment to continuous improvement and quality assurance. Leading manufacturers employ rigorous quality control measures to ensure each grate meets specific engineering criteria before it reaches the consumer. This vigilance instills confidence among users, knowing they are investing in a product with a proven track record and an illustrious pedigree. On the trustworthiness scale, suppliers of galvanized safety grating bolster their reputation by pinpointing their product's performance post-installation. Numerous case studies and customer testimonials serve as a testament to the enduring quality and reliability that these gratings represent. By documenting real-life applications and identifying areas of ongoing research and enhancement, the industry supports a narrative of dependability and client-centric innovation. To sum up, galvanized safety grating embodies the principles of Experience, Expertise, Authoritativeness, and Trustworthiness through its robust design, ease of application, and ongoing industry endorsement. Its implementation across varied sectors not only showcases its versatility but also guarantees an environment where safety, efficiency, and aesthetics coalesce. As businesses continue to place a premium on products that deliver on all fronts, galvanized safety grating stands out as a premier choice for those looking to enhance operational safety without compromise. As such, it remains an integral component in modern industrial design, proving its value time and again by addressing current challenges and anticipating future needs.

In addition to practicality, galvanized safety grating lends itself to aesthetic applications. The sleek, metallic look integrates seamlessly into more contemporary designs, offering both functionality and visual appeal. This makes it highly relevant to architects and designers looking to incorporate industrial chic elements into their projects. The aesthetic component, while secondary to safety and durability, is nevertheless a value-add that should not be underestimated. Perhaps one of the most reassuring aspects of using galvanized safety grating is the industry’s commitment to continuous improvement and quality assurance. Leading manufacturers employ rigorous quality control measures to ensure each grate meets specific engineering criteria before it reaches the consumer. This vigilance instills confidence among users, knowing they are investing in a product with a proven track record and an illustrious pedigree. On the trustworthiness scale, suppliers of galvanized safety grating bolster their reputation by pinpointing their product's performance post-installation. Numerous case studies and customer testimonials serve as a testament to the enduring quality and reliability that these gratings represent. By documenting real-life applications and identifying areas of ongoing research and enhancement, the industry supports a narrative of dependability and client-centric innovation. To sum up, galvanized safety grating embodies the principles of Experience, Expertise, Authoritativeness, and Trustworthiness through its robust design, ease of application, and ongoing industry endorsement. Its implementation across varied sectors not only showcases its versatility but also guarantees an environment where safety, efficiency, and aesthetics coalesce. As businesses continue to place a premium on products that deliver on all fronts, galvanized safety grating stands out as a premier choice for those looking to enhance operational safety without compromise. As such, it remains an integral component in modern industrial design, proving its value time and again by addressing current challenges and anticipating future needs.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP