Understanding Floor Grating Panels A Comprehensive Overview

Floor grating panels are essential components in various industrial and commercial settings, playing a crucial role in safety, functionality, and design. These panels, often made from materials such as steel, fiberglass, or aluminum, are designed to provide a sturdy surface that allows for effective drainage while supporting heavy loads. Understanding the characteristics and applications of floor grating panels is vital for engineers, architects, and facility managers as they navigate the complexities of modern construction and infrastructure design.

Types of Floor Grating Panels

There are several types of floor grating panels, each tailored to specific environments and uses. The most common types include

1. Steel Grating Known for its strength and durability, steel grating is widely used in industrial environments. It comes in various forms, including welded, pressed, and riveted gratings, providing flexibility for different load requirements.

2. Fiberglass Reinforced Plastic (FRP) Grating This type is particularly popular in environments prone to corrosion, such as chemical plants and wastewater treatment facilities. FRP grating is lightweight, non-conductive, and resistant to various chemicals, making it an excellent choice for challenging conditions.

3. Aluminum Grating Lightweight and resistant to corrosion, aluminum grating is often used in less demanding environments or where weight is a factor, such as walkways and platforms. Its aesthetic appeal also makes it suitable for decorative applications.

4. Plastic Grating Often used for drainage purposes in both commercial and residential settings, plastic grating is lightweight and resistant to various elements. It is ideal for environments where ease of installation and maintenance is prioritized.

Advantages of Floor Grating Panels

floor grating panels

1. Safety One of the primary advantages of using floor grating panels is enhanced safety. The open design of grating facilitates runoff and drainage, minimizing slip hazards in wet conditions. Additionally, the load-bearing capacity provides a secure walking surface for personnel and equipment.

2. Ventilation Grating panels allow for airflow, reducing heat buildup in industrial settings and promoting improved ventilation. This feature is particularly beneficial in environments with high-temperature equipment or chemical processes.

3. Cost-Effectiveness Utilizing floor grating panels can be a cost-effective solution. Their durability means less frequent replacement, while their lightweight nature can reduce transportation and installation costs.

4. Versatility Floor grating panels can be used in a myriad of applications, from industrial workplaces to commercial settings. They can be customized to fit various configurations, making them suitable for both large-scale projects and smaller installations.

Installation and Maintenance

The installation process for floor grating panels varies depending on the type and the intended use. Steel gratings, for example, may require welding or fastening, while FRP grating can be installed with simple tools. Proper maintenance is essential to ensure the longevity of the panels. Regular inspections for wear and tear, particularly in high-traffic areas, can help prevent accidents and extend the lifespan of the materials.

Conclusion

Floor grating panels are critical elements in the design and function of modern infrastructures. Their safety features, versatile applications, and cost-effectiveness make them indispensable in many settings. By understanding the different types available and their specific advantages, stakeholders in construction and facility management can make informed decisions that enhance both safety and functionality. With the right choice of floor grating panels, the benefits extend beyond mere aesthetics, contributing to a safer and more efficient working environment.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

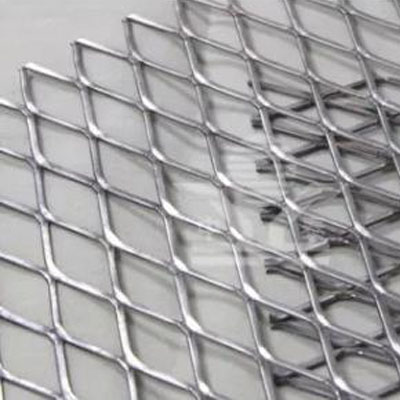

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.