Understanding Metal Grating Price

When selecting metal grating, one of the first considerations is the metal grating price. The price varies depending on the type of material, size, and application. Metal grating price can be influenced by factors such as the thickness of the bars, the finish, and whether the product is custom-made. Typically, higher-grade materials or special finishes will raise the cost, but they also provide enhanced durability and longer-lasting performance. It's essential to balance quality and budget when considering metal grating price for your project.

What Is Twisted Bar Grating?

Twisted bar grating is a unique type of grating known for its exceptional strength and aesthetic appeal. Made from twisted bars of metal, this type of grating is often used in environments where both durability and visual impact are important. Twisted bar grating is commonly found in architectural designs, walkways, platforms, and other industrial applications. The twisting process gives the grating a distinctive look while providing added resistance to stress and wear, making it ideal for both practical and decorative purposes.

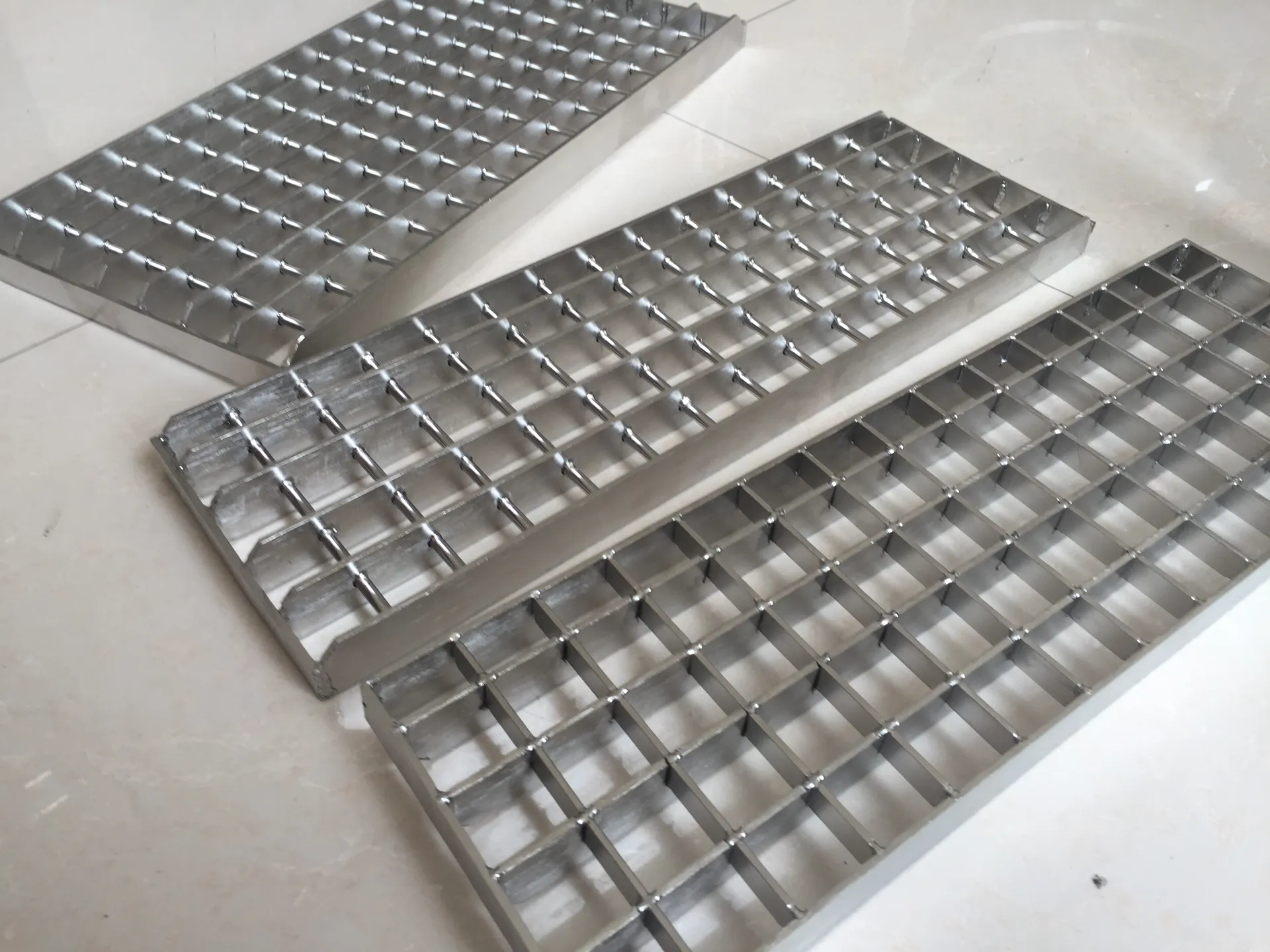

Benefits of Steel Mesh Floor Grating

Steel mesh floor grating is an excellent option for providing a solid, non-slip surface in high-traffic areas. This type of grating is made from welded steel mesh, which offers superior strength and load-bearing capacity. Steel mesh floor grating is often used in industrial settings, factories, and warehouses where high durability is required. Its design allows for easy drainage and airflow, making it a practical choice for areas exposed to water, chemicals, or debris. The open mesh structure also reduces the risk of slips and falls, ensuring safety in the workplace.

Advantages of Painted Steel Grating

For applications where aesthetics and corrosion resistance are important, painted steel grating offers a great solution. This type of grating combines the strength of steel with a protective coating that resists rust and weathering. Painted steel grating is ideal for outdoor applications, providing not only durability but also an attractive finish. The paint can be customized to match specific color requirements, making it suitable for both functional and decorative purposes. The protective coating helps extend the lifespan of the grating, ensuring long-term reliability in harsh environments.

Choosing the Right Metal Grating for Your Needs

When selecting the right type of metal grating for your project, it's important to consider factors such as load-bearing requirements, environmental conditions, and design preferences. Whether you are looking for twisted bar grating, steel mesh floor grating, or painted steel grating, each type has its own set of benefits that cater to different needs. By understanding the specific requirements of your project, you can choose the most appropriate type of metal grating that offers both durability and value for money.

Selecting the right metal grating is crucial to ensuring both functionality and safety in your project. Understanding the metal grating price, benefits of twisted bar grating, the advantages of steel mesh floor grating, and the protective qualities of painted steel grating will help you make an informed decision. No matter your requirements, there is a metal grating solution available to meet your needs, offering the perfect blend of performance and design.

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

-

Comprehensive Guide to Twisted Bar Grating – Uses, Benefits & Future Trends

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.