Understanding Filter Tubes An Essential Component in Filtration Systems

In the evolving landscape of industrial processes, environmental management, and water purification, the role of filter tubes cannot be overstated. These tubular components are integral in various applications, ranging from air purification systems to water treatment facilities. Their primary function is to facilitate the filtration of unwanted particles, ensuring the output is clean and safe for use, which is increasingly important as global pollution levels rise and the demand for clean resources intensifies.

What are Filter Tubes?

Filter tubes are cylindrical devices designed for the purpose of separating solids from liquids or gases. Generally made from materials such as polypropylene, stainless steel, or specialized polymers, these tubes feature a permeable wall that allows fluid to pass while trapping impurities inside. They come in various sizes, shapes, and mesh configurations, catering to the specific needs of different applications.

The design and material choices for filter tubes are critical, as they must withstand various pressures and temperatures while maintaining their efficiency over time. Some filter tubes are designed for single use, while others can be cleaned and reused, which is an important consideration for waste reduction and cost-effectiveness in industrial settings.

Applications of Filter Tubes

Filter tubes have a wide range of applications across various industries, reflecting their versatility and effectiveness. In water treatment, for instance, they play a crucial role in sedimentation processes, removing suspended solids and ensuring that potable water meets safety standards. In the pharmaceutical industry, filter tubes are essential for ensuring that products are free from contaminants, thus protecting consumer health and adhering to regulatory standards.

In air purification, filter tubes are used within systems designed to improve indoor air quality

. They capture airborne particles, allergens, and other harmful substances, making the environment safer for occupants. Additionally, in industrial applications, these tubes are often found in chemical processing, where they filter out contaminants to protect machinery and improve product quality.The Mechanics Behind Filter Tubes

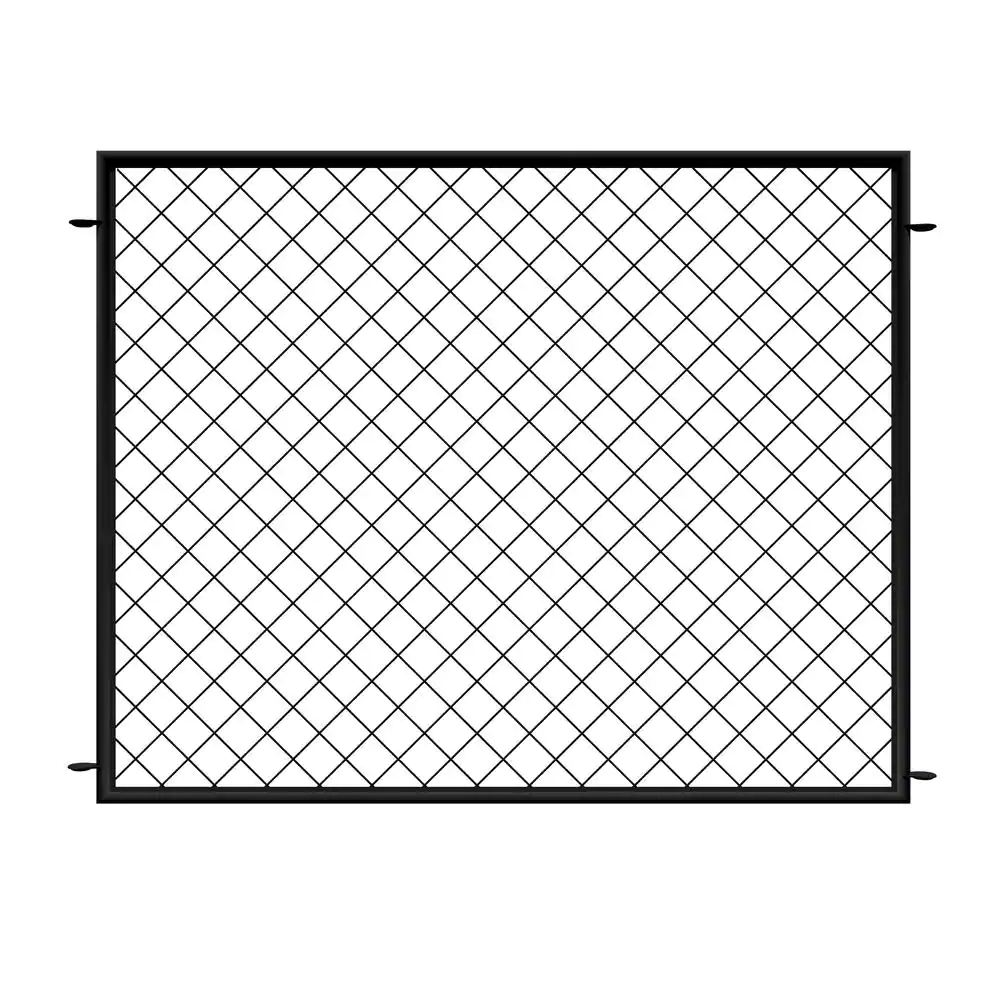

filter tube

The effectiveness of a filter tube lies in its filtration mechanism, which can vary significantly depending on the application. Generally, the two primary methods of filtration utilized by these tubes are depth filtration and surface filtration.

Depth filtration involves trapping particles within the thickness of the filter material. This method is effective for removing larger particles from liquid or air streams and is often employed in applications requiring pre-filtration or the elimination of significant levels of impurities.

In contrast, surface filtration captures particles on the surface of the filter medium. This method is highly effective for finer filtration and is generally used in applications like air filtration systems, where even the smallest pollutants need to be captured.

Maintenance and Replacement of Filter Tubes

To ensure optimal performance, regular maintenance and replacement of filter tubes are essential. Over time, filters can become clogged with debris, leading to decreased efficiency and potential system failures. The frequency of replacement depends on various factors, including the type of materials being filtered, the flow rate, and the operating environment.

Organizations often utilize monitoring systems to track the performance of filter tubes, prompting replacement before issues arise. This proactive approach not only protects the filtration system but also extends the lifespan of the equipment it serves.

Conclusion

In conclusion, filter tubes are indispensable components in a wide range of applications, playing a critical role in maintaining the quality of air and water. As industries continue to evolve and the need for pollution control becomes more pressing, the development and implementation of efficient filter tube systems will remain a priority. Understanding their design, applications, and maintenance requirements is essential for ensuring their effectiveness and longevity. As we move towards a more sustainable future, the contribution of filter tubes to cleaner environments will be increasingly recognized, highlighting the importance of innovation in filtration technologies.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.