Exploring Extruded Metal Mesh Versatility and Applications

Extruded metal mesh has emerged as a preferred choice in various industries due to its remarkable strength, durability, and versatility. Unlike traditional woven or welded meshes, extruded metal mesh is manufactured through an innovative process that involves the extrusion of metal, typically aluminum or stainless steel. This results in a lightweight yet robust product, making it suitable for a myriad of applications.

One of the key advantages of extruded metal mesh is its exceptional structural integrity. Extrusion allows manufacturers to create complex profiles and designs that would be difficult to achieve with other methods. The resulting mesh exhibits uniform strength and even distribution of material, which means it can withstand significant loads and resist bending or deformation under stress. This characteristic makes it ideal for use in construction and architectural applications, where safety and stability are paramount.

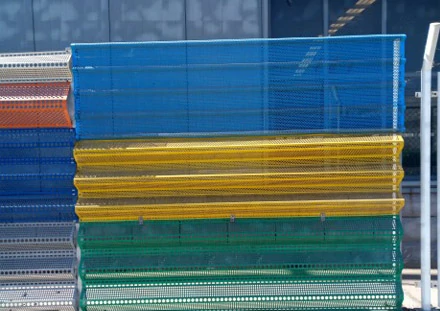

In the architectural field, extruded metal mesh is gaining popularity for both aesthetic and functional purposes. It is often used in facades, canopies, and as decorative elements in buildings. The unique appearance of extruded metal mesh adds a contemporary touch to architectural designs, allowing for light filtration while maintaining privacy. Additionally, its durability ensures that it can withstand harsh weather conditions, making it suitable for exterior applications.

Another sector that benefits greatly from extruded metal mesh is the filtration industry. The fine openings in the mesh can be tailored to filter out specific particles, making it an excellent choice for air, liquid, and sound filtration. Industries such as food and beverage, pharmaceuticals, and chemical processing extensively utilize extruded metal mesh for separating impurities and ensuring the highest levels of product purity. Furthermore, its corrosion resistance enhances its longevity in demanding environments.

extruded metal mesh

Moreover, the automotive and aerospace industries rely on extruded metal mesh for components that require strength without adding excessive weight. From interior structures to safety features, the lightweight properties of extruded metal mesh provide an edge in enhancing fuel efficiency and performance. The ability to customize the dimensions and properties of the mesh enables engineers to develop innovative solutions that meet stringent industry standards.

In the realm of industrial applications, extruded metal mesh is often employed in safety barriers, grating systems, and even conveyor belts. Its resilience to wear and tear ensures that it can withstand harsh operating conditions while providing security and accessibility. For instance, in mining and heavy manufacturing, extruded metal mesh serves as protective screens and containment solutions, ensuring safety for workers and machinery.

Sustainability is another important consideration in today’s manufacturing landscape, and extruded metal mesh shines in this regard. Aluminum and stainless steel are both recyclable materials, and the extrusion process generates less waste compared to other manufacturing methods. This aligns with the growing demand for eco-friendly products and practices across various industries.

In summary, extruded metal mesh is a multifaceted product that plays a crucial role in numerous sectors. Its combination of strength, versatility, and aesthetic appeal positions it as a frontrunner in modern manufacturing and design. As industries continue to innovate and evolve, the demand for extruded metal mesh is expected to grow, leading to more advanced applications and improved manufacturing techniques. Whether it's enhancing building designs, improving filtration processes, or contributing to the automotive sector, extruded metal mesh is undoubtedly a critical component of contemporary industrial solutions.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.