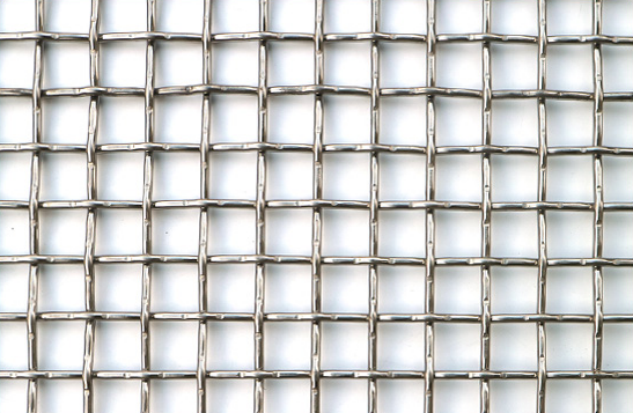

Understanding Extruded Metal Mesh A Versatile Solution for Modern Applications

Extruded metal mesh is a sophisticated material engineered for various applications across multiple industries. Utilizing the extrusion process, metal is forced through a die to create a mesh structure with specific dimensions and characteristics. This technique not only enhances the physical properties of the metal but also allows for the production of intricate designs that would be challenging to achieve with conventional fabrication methods.

One of the key benefits of extruded metal mesh is its lightweight nature combined with impressive strength. The extrusion process helps maintain the structural integrity of the metal while reducing unnecessary weight. This makes extruded metal mesh an ideal choice for applications where both strength and weight efficiency are critical, such as in the aerospace and automotive industries.

In addition to aerospace and automotive, extruded metal mesh is widely used in architectural applications. Designers and architects favor this material for its aesthetic appeal and functionality. The perforated patterns can be crafted to allow for natural light while providing privacy, making it a popular choice for facade treatments, sunshades, and decorative elements in modern buildings. Moreover, extruded metal mesh is often used in fencing and screening applications, where visibility and airflow are essential while maintaining security.

The versatility of extruded metal mesh extends to the industrial sector as well. It is commonly employed in manufacturing environments for safety barriers, workstations, and shelves. The open structure of the mesh offers excellent ventilation and visibility while maintaining containment, which is crucial for workplaces that prioritize safety and efficiency.

extruded metal mesh

Another significant advantage of extruded metal mesh is its corrosion resistance

. Depending on the type of metal used—be it aluminum, stainless steel, or other alloys—the material can be treated or coated to withstand harsh environmental conditions. This is particularly advantageous for applications in marine environments, chemical processing facilities, and other settings exposed to moisture and contaminants.Furthermore, the maintenance of extruded metal mesh is minimal, contributing to its appeal in various applications. Unlike traditional materials that may require frequent maintenance or replacement, extruded metal mesh typically retains its appearance and function over time, thereby reducing long-term costs.

The customizability of extruded metal mesh is another factor driving its popularity. Manufacturers can produce mesh with varying apertures, thicknesses, and patterns to meet the specific needs of clients. This adaptability makes it suitable for diverse applications, ranging from filtration systems to decorative art installations.

As industries continue to seek innovative materials that combine functionality with aesthetic appeal, extruded metal mesh stands out as a leading choice. Its unique properties, combined with the ability to customize designs, ensure that it will remain a relevant and essential material in the years to come. Whether in architectural design, industrial applications, or safety solutions, extruded metal mesh proves to be a versatile and valuable asset across multiple fields.

In conclusion, extruded metal mesh is an exceptional material that brings together lightweight strength, aesthetic appeal, and durability. Its flexible applications allow it to meet the evolving demands of modern industries, making it an integral part of contemporary design and engineering solutions.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.